THE RESCUE COMPANY ❘ By JAKE HOFFMAN

As fire departments across the nation are tasked with additional responsibilities such as emergency medical services (EMS), community risk reduction, public education, and others, it has become even easier for perishable skills such as those needed for technical rescues to become rusty. Although technical rescue incidents are rare, the public will undoubtedly call you for these high-risk/low-frequency events and expect you to know what to do or to call someone who does. Just as fire preplans are essential tools in developing a game plan prior to a fire occurring in a structure, departments should not overlook the importance of developing a technical rescue preplan.

You can conduct preplans for firefighting operations easily in public facilities or buildings to which the fire department responds frequently. However, obtaining access to high-hazard locations such as industrial facilities, construction sites, and high-rise rooftops may be difficult without advance coordination with building personnel. Therefore, the technical rescue preplan is especially valuable for crews who may not have been able to attend the walk-through because of calls, working a different shift, and so on.

RELATED FIREFIGHTER TRAINING

Technical Rescue Response: Awareness First for Safety

Implementing and Maintaining an Effective Technical Rescue Team

Training the Technical Rescuer

(1) The superintendent of a shipyard welcomes rescuers as they begin a preplan of the facility, including a large freighter in dry dock. (Photos courtesy of author.)

The Basics of the Preplan

When brainstorming locations to preplan, consider previous incidents, news stories, tips obtained from fire inspections or other fire crews, or even an invitation from facility personnel. Even if the location to be preplanned is easily accessible to fire crews, they should always attempt to arrange in advance as a courtesy and to ensure a knowledgeable person can accompany the crews on the walk-through.

Developing a preplan worksheet to assist crews in obtaining the needed information is imperative for ensuring that pertinent information is not overlooked. Basic information needed on all technical rescue preplans includes street addresses and any other locations to where crews could be called (other gates or addresses); the number of workers/occupants per shift or time of day; 24-hour contact information for security, maintenance, management, or other important personnel; and any basic information on the site (e.g., a 46-story, mixed-use high-rise or a 35-million-gallon underground storm water retention tank).

(2) The “Scenarios” section of a rescue prelan.

(3) In addition to offering a potential rescue scenario, tower cranes also provide a terrific training platform.

A diagram of the location will also be very helpful for responding crews; if you cannot obtain one from on-site personnel, take notes and pictures so you can develop an accurate diagram using a satellite view such as Google Earth. Next, include a brief description of the location and the work being performed so all responding personnel have a basic understanding of what normal operations include. Follow this with general safety considerations that all responders should follow, which includes needed personal protective equipment, access/parking instructions, communications information (if normal radio use may be difficult or impossible), security concerns, and any other information deemed necessary.

Following is other information that may prove useful for your technical rescue preplan:

- Floor plans and diagrams.

- Hazardous materials stored on scene and how they could affect a rescue operation.

- The number of confined spaces on site (include diagrams/photos whenever possible).

- Access challenges for confined spaces (e.g., limited headspace that does not allow for a tripod).

- Overview of the project and hazards found.

- Response and staging considerations.

The “Scenarios” Section

The main part of the technical rescue preplan is the “Scenarios” section where crews brainstorm the potential emergencies that may occur and how to respond to them. Begin this portion of the preplan process by asking building or facility personnel what they believe are their “worst-case scenarios.” An easy way to start this process is by asking facility personnel to identify all confined spaces, especially those that require a permit. Sketch out each space and list the hazards present that make it a permit-required space. Also, note the location of safety controls and power supplies so that, in the event of an emergency, arriving crews can isolate them without delay. Ask for copies of maps, plant diagrams, and so on that could prove useful to crews in the future.

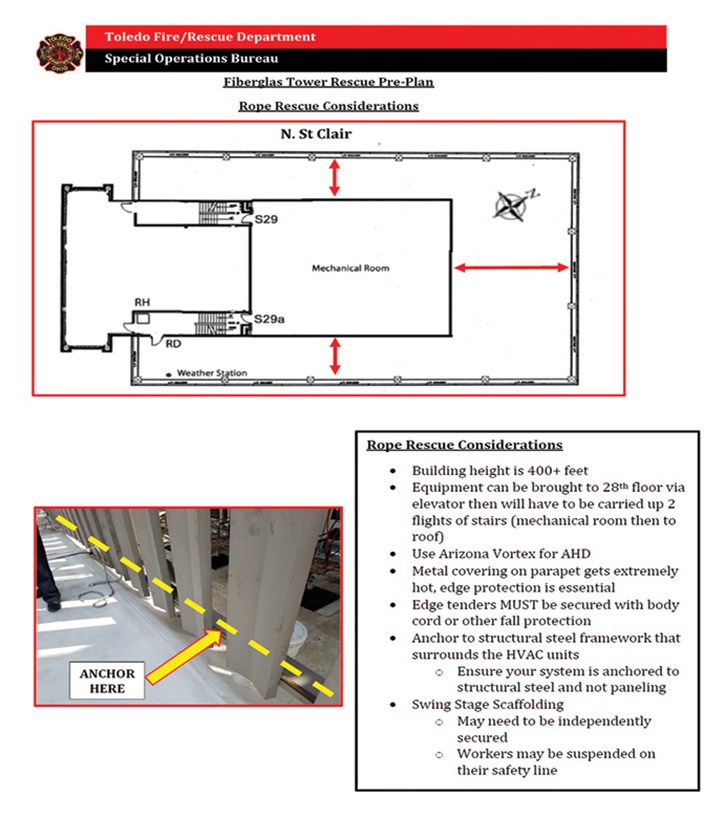

(4) Include photos of potential anchor points for rope rescue systems in your rescue preplan.

(5) Note access challenges in a rescue preplan. This machinery is located atop a 150-foot-tall grain silo with limited access, lengthening the time it will take for equipment to arrive. Consider a “recon” team at facilities with access challenges.

(6) Maintenance personnel offer a wealth of knowledge during preplanning and incident response.

In industrial settings, lockout/tagout and energy control are essential to not only a successful outcome but also the safety of fire/rescue personnel. While conducting the rescue preplan walk-through, rescuers should have facility personnel identify the location of energy control and demonstrate how it is secured. If the fire department does not have lockout/tagout equipment or has the equipment but does not have a device needed to lock out a specific valve, switch, and so on, ask the facility to donate one to your department. Even if these devices are kept on site for routine maintenance work, they inevitably will be used elsewhere or not be found when needed for a rescue.Even if lockout/tagout equipment has been placed prior to the arrival of the technical rescue team, send a rescuer to verify that lockout/tagout is in place and to apply his own lock and tag to the device in question.

Once facility personnel have identified their scenarios, have rescuers develop realistic scenarios they could eventually face. These scenarios could include window washer scaffolding failure, tunnel collapse, conveyor entrapment atop a grain elevator, machinery entrapment, difficult locations to access, and so on. Accompany each scenario with pictures and a description of the potential scenario and list a “Plan A” option to mitigate the emergency. Information such as rigging points, which elevators reach the roof, environmental concerns, and so on are essential to not only describe but also show through pictures or diagrams. Include a basic list of needed equipment for each scenario; the list doesn’t have to be all-inclusive.

Identifying potential rooftop anchor points for rope rescue systems should be the foundation of any preplan involving high-rise buildings or other elevated areas where rescues could occur. Inevitably, these anchors will not be ideally located when an incident does occur, but by preplanning the options available, rescuers can more easily develop a comprehensive rigging plan involving directional anchors, tiebacks, and so on.

If the facility allows, you can use these scenarios in training to provide technical rescue team members with realistic, scenario-based training at an unfamiliar location. Although this type of incident may not ever occur at the facility where you conduct the training, firefighters will become more accustomed to operating in unfamiliar environments such as industrial facilities, construction sites, bridges, and so on; this will improve their competency and capabilities for all technical rescue incidents.

Industrial Facilities

When operating in industrial facilities, rescuers must also consider the prevalence of automation technologies and robots. Not only can these devices prove hazardous to rescuers if they do not recognize and mitigate them, but they can also cause the incident to which you have responded. Many modern manufacturing and warehouse operations use automation to streamline their operations. No longer are these technologies limited to a particular skill such as welding or a fixed location such as an assembly line. “Free range” robots that operate completely independent of any direct human guidance are being found in many industrial facilities.

If you find these technologies in the facility being preplanned, ask questions related to this unique 21st-century hazard such as the following:

- How can we disable these robots/vehicles?

- Keep in mind that “time is money” for these large operations. Although the primary concern should be the patient, if you do not have to shut down robots on the opposite side of a large factory, don’t.

- Are the robots isolated to one particular area or are they “free range”?

- If isolated, lockout/tagout is essential prior to entering the machine’s space.

- If they are “free range,” consult with facility personnel to determine safe ways to operate near these machines. Robots use multiple technologies to “see” the world around them including lasers and radar. Even if the machines close to the rescue site are shut down, a firefighter may encounter one while retrieving additional equipment from the apparatus.

Community Partnerships

An underrated benefit of conducting technical rescue preplans is the development of public or private partnerships with the community. Corporate social responsibility (CSR) is defined by the Business Dictionary as, “A company’s sense of responsibility towards the community and environment (both ecological and social) in which it operates.” Collaborative efforts such as technical rescue preplans and training are an easy way for organizations to help fulfill their CSR goals.

In the modern business world, corporations are eager to demonstrate that they wish to improve not only their bottom line but also their communities. An easy way to accomplish this task that serves as a win-win for all involved is through training and collaboration with the fire department. The fire department public information officer can use his media contacts to publicize this partnership, which shows all involved parties in a positive light.

Additionally, sending a simple “thank you” letter to organizations stating that the technical rescue team was successful in its training, preplans, and so on shows your appreciation for the cooperation of your community partners. Many times, these organizations will frame these letters and hang them on their walls to prominently illustrate their commitment not only to the community but also to the safety of their workers.

Although preplans are often thought of as being useful only for firefighting activities, if you conduct them with technical rescue incidents in mind, they will help the technical rescue team perform more efficiently during emergencies, demonstrate a company’s commitment to the safety of their workers, and develop relationships with external agencies that provide good publicity and long-lasting benefits for all parties involved.

If you need to call an external agency such as another fire department or regional technical rescue team for an incident, identify target hazards in your response area and invite the technical rescue team to conduct preplans and train whenever possible. Not only will this familiarize the technical rescue team with potential rescue scenarios, but it will undoubtedly foster cooperation between departments. Building relationships through events such as this will pay dividends when an incident occurs.

For many departments, the monetary and training concerns of operating an all-hazards technical rescue team are too great; they either depend on another department or a regional rescue team to provide these services. When a fire department is dependent on other agencies to assist during technical rescue incidents, it must first take a realistic look at its own capabilities to understand its limitations and to identify whom it can call for assistance. Obtain 24/7 contact information for the technical rescue team so you can request assistance early in the incident so as not to delay the start of rescue operations.

JAKE HOFFMAN is a private with the Toledo (OH) Fire & Rescue Department assigned to Rescue Squad 7, one of the city’s two heavy rescue companies. He serves as a member of FEMA Ohio Task Force 1 and was on the technical panel for the Underwriters Laboratories fire attack and victim survivability study.