Something in Common:

INDUSTRIAL FIRE PROTECTION

For International Business Machines Corp., the world’s largest computer manufacturer, coming up with a couple of personal computers and some programmers’ time at its Rochester, Minn., plant was a simple matter. And for the Rochester Fire Department, having a hazardous materials team on hand was just as routine; it was already in place a minute away from the plant, at Station 4.

The special ingredient that brought a major corporation and a local fire department together in preincident planning—and joint training—was the proactive attitude shared by both.

IBM Rochester, with 7,000 employees and 3.6 million square feet under one contiguous roof, has a long history of emergency response preparedness. In 1956, the plant organized a fire brigade for incipient firefighting, composed of about 70 maintenance and security workers. A medical response team, with 240 first aiders sitewide, goes back to 1965. And a chemical spill team 50 persons strong began operating five years ago. The fire and spill teams are joining into one unit of about 40 people that will also handle rescue. All the responders are volunteers from the work force.

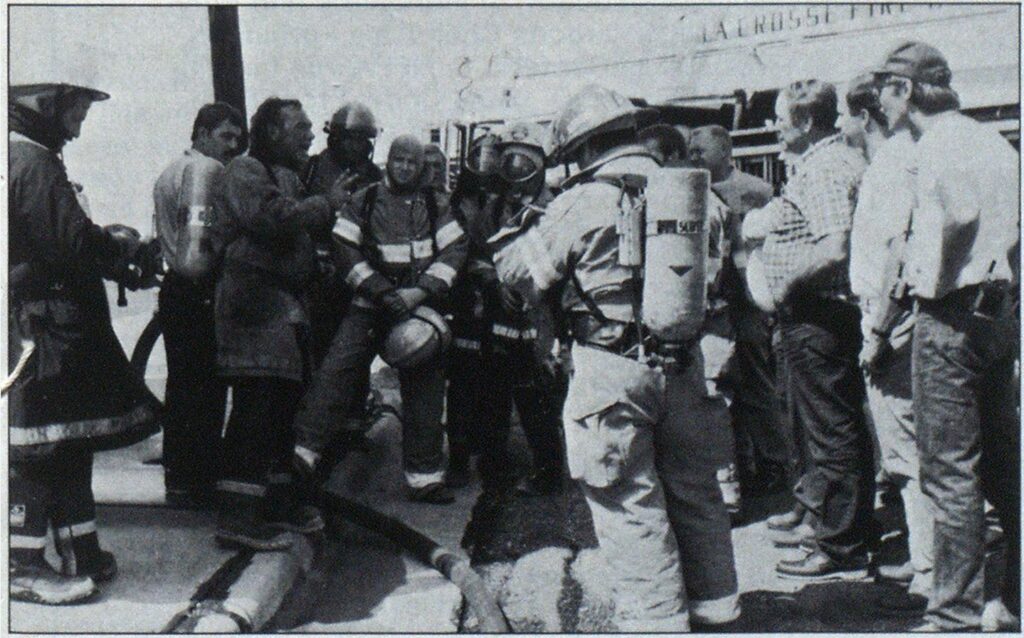

The spill team planted the seed for cooperation between IBM and the Rochester Fire Department in July of 1985 after spending some time 70 miles away, crawling through a fire maze training trailer at Western Wisconsin Technical Institute in La Crosse. The trailer is used to simulate a smoky atmosphere; firefighters train in it blindfolded while wearing their turnout gear and self-contained breathing apparatus.

“We’d been looking for a vehicle for joint training” with the fire department, says Victor Vickmark, emergency response team coordinator in IBM’s safety engineer department at Rochester. The strenuous workout in WWTI’s trailer gave the spill team “confidence in themselves and in their equipment. They suggested it as training for the fire department as well, so we decided it was a good place to start training together.”

IBM added some incentive by, buying an extension course from’ WWTI, bringing the trailer to Rochester in October of last year, and hiring a La Crosse Fire Department training officer to run simulations of chemical leaks. The corporation footed the bill for both Rochester firefighters and smaller departments in the area.

There was no particular incident at the plant that sparked the interest in cooperation, the parties involved say. Instead, responders on both sides took their cue from the potential for an incident.

IBM Rochester makes two product lines: midsize computers and disks for data storage. It also performs research and development. Thousands of chemicals have a place at the plant, in quantities from a few ounces to several thousand gallons—enough to require an outside tank farm. The substances range from acetone used in general cleaning, to freons used in cleaning computer parts, to kerosene used in cooling drill presses.

Rochester firefighters and a local IBM plant joined in preplanning because they shared an outlook.

(Photo by Marlene Lake)

“Since we do work with a large number of chemicals on a daily basis, we have personnel whose knowledge of chemicals can be a very valuable resource both for training and in the event of an incident,” says Vickmark.

That information had to be augmented by what the fire department knew about how the chemicals would behave after ignition, as Gerald Loftus, a captain of the Rochester Fire Department’s hazardous materials team, points out. “The IBM response team members who have worked with chemicals in a controlled state were not totally aware of chemical behavior in fire conditions,” says Loftus, who’s also in charge of the department’s training programs. For instance, although harmless when not burning, fluorocarbons give off highly poisonous phosgene gas when they burn, and kerosene becomes as explosive as gasoline.

Information of that type is going into a cooperative preplanning document. And IBM is providing more data than it’s required to make available under Minnesota’s Commodity Disclosure Act. “We could hand the fire department copies of all the material safety data sheets we have on file,” says Vickmark, “but that’s not the type of information they need when responding to an incident or fire at our location.” IBM is cooperating by “physically going through each and every building, listing in detail exactly what information the fire department would need.”

The computerized document will provide emergency responders with information in printed form or electronically within three or four minutes of an alarm. The personal computers to make it available are in three places: the fire department (Station 4 and dispatch); the IBM command center, to which the incident commander responds; and the IBM spill cart, to which the operational commander responds. The cart is a trailer, pulled by a golf cart, which carries extinguishing supplies, encapsulating suits, and reference materials.

Part 1 of the document is a general diagrammatic layout of each building, showing floor plans and the locations of chemicals, fire hose cabinets, extinguishers, emergency exits, and so on. Part 2 lists types and quantities of chemicals present in each of the plant’s 31 buildings. Part 3 gives control procedures for fires and chemical spills, as well as listings of special protective clothing, extinguishing procedures, containment and cleanup procedures, and decontamination processes.

The document stays up to date because all changes in chemical usage at the plant must go through IBM Rochester’s chemical distribution group for approval, and the person who manages the document is involved in that loop.

The information-sharing process does more than put data at the ready for emergency responders; it gives responders a chance to prepare by making sure they have the appropriate equipment. The fire department checks the encapsulating suits it has on hand. If they’re not appropriate for all the chemicals firefighters could come in contact with at the IBM Rochester site, the department must provide room in the budget for others that are, Capt. Loftus points out.

Noting that the Rochester Fire Department is putting a lot of its emergency response information on computer, Loftus says the IBM haz-mats project “is going to be a model for how we do preplanning communitywide.”

The hazardous materials team leader views it as part of a progressive trend. “I think what we’re seeing is a new generation in the fire service,” Loftus says. “We’re trying to be proactive instead of reactive.”