RESCUE TEAM SCRUBS UP FOR EXTRICATION

RESCUE COMPANY

“Tower One, respond to emergency at Orlando Regional Medical Center emergency room with hydraulic power cutter; industrial equipment extrication.”

As we responded down South Orange Avenue we reviewed our extrication SOP.

I waited with the rest of the crew while Lieutenant Joe Samillano and our forcible entry man entered the hospital to size up the situation. Shortly thereafter we received a message over the radio from Lt. Samillano to come inside.

In the emergency room an apprehensive but quiet young man was the center of a great deal of attention. His arm was trapped inside a commercial pasta machine. A roomful of emergency personnel hovered over him, taking vitals, applying monitor patches, and starting IVs.

His arm had been pulled down into the stainless steel hopper and was wrapped around the mixing shaft. There were numerous breaks in his arm’s radius and ulna. Two of the ½- inch-by-5-inch mixing rods extending from the shaft had completely penetrated his arm. There was little bleeding because the brachial artery was compressed by the hopper’s inside wall.

Our job was to remove the man’s arm from the hopper, but how?

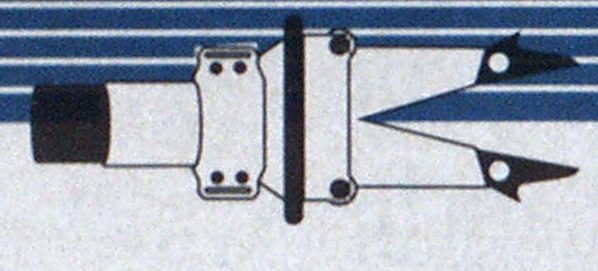

We believed that the safest course of action would be to separate the hopper from the rest of the mixer assembly, thereby providing medical personnel with the room to work the arm free of the mixing rods. We ruled out a cutting torch immediately because the space was too confined and the patient would be placed at too great a risk. Dismantlement wasn’t a possibility because the special tools required to assemble and disassemble that particular piece of equipment were unavailable —it couldn’t be done with standard work tools. We felt that a power saw should be used only as a last resort because besides the considerable noise and engine fumes it generates, its size would leave little margin for error while working in such a confined space. Finally, we decided to remove the hopper from the mixing shaft with a pneumatic whiz saw because it is maneuverable and compact and capable, we felt, of making the necessary cuts on the stainless steel hopper.

Lt. Samillano explained to the doctors how the tool works, what equipment would be needed, and the risks associated with using such a tool. The doctors agreed with his decision to use the whiz tool and in turn advised him that the removal attempt would be best facilitated in the operating room for three reasons: The patient would have to be anesthetized, doctors could control more effectively the possibility of infection and blood loss, and equipment and personnel would be in place should the extrication attempt fail and amputation become necessary.

With the help of operating room personnel we procured the equipment needed for the extrication attempt-air hoses, wrenches, safety goggles, and a carbon dioxide fire extinguisher. Since the operating room’s air connectors had female threads and the whiz tool required male threads, we brought our unit’s 300-cubic-foot air cylinder to the operating room. All equipment had to be cleaned thoroughly before we could take it into the operating room. Before entering, we scrubbed and were outfitted with surgical clothes.

Lt. Samillano explained to all personnel that cutting the stainless steel would produce sparks and smoke and throw metal shavings around the room. He made certain that there were no flammable or explosive materials in the operating room that could be ignited by sparks. The patient was administered oxygen through a mask fed off the hospital oxygen supply, and this did not present a significant hazard. The lieutenant requested that a firefighter stand ready with the fire extinguisher during the entire operation; this precaution not only minimized the chances of the hospital bedding catching fire but also served to ease the tensions of hospital personnel, because this was an unusual incident for them as well as for us, and they were not used to sparks and smoke in their operating room. Our communications center personnel were advised of what was about to take place in case they received a mechanical alarm initiated by the operating room’s smoke detectors.

After all equipment was set up and checked and the patient was anesthetized and intubated, we were given the go-ahead. All personnel donned eye protection. We made two long hut incomplete cuts along the underside of the hopper, stopping ⅛ inch short of a complete cut at each of the four corners. We were concerned that if we made the first cut from one end to the other, the hopper could shirt and release pressure on the artery, resulting in large blood loss. The two cuts were made using two compositetype blades and 1,000 pounds of air at 90 to 100 psi. Then we installed a new blade so that the final cuts at the four corners of the hopper could be made without interruption. Members were positioned to secure the hopper and prevent sudden shifting.

lhe four ⅜-inch cuts were completed about 1 5 minutes after we had begun the operation, and the hopper was removed. Personnel carefully rolled the young man’s arm out of the mixing shaft. The extrication procedure was a success, as was the subsequent surgery to restore the use of the man’s arm and hand.

It was an exciting experience working alongside highly skilled surgeons and knowing that our actions were as important as theirs. Sometimes we re called on to perform unusual and interesting tasks. But we must remember that the many mundane and unglamorous tasks we perform every day are equally important to public safety and require our maximum effort as well