Louisville Engine Company Doubles As City wide Haz-Mat Response Team

features

Like a number of progressive fire departments throughout the country, the Louisville Fire Department is experimenting to find the most efficient and effective hazardous materials response and control organization from among a number of alternatives.

The Louisville department, with 23 engine and 10 truck companies, initially operated a special two-man chemical unit for a year but felt it was underutilized. On Sept. 16, 1979, Louisville combined the chemical unit apparatus with an additional engine to form Engine Company 15, which operates as a regular engine company in a limited area and as a hazardous materials team citywide.

Engine 15 is staffed by three platoons with a captain, two sergeants, and three fire fighters in each platoon. Personnel, who all volunteered for the assignment, are on duty 24 hours and off 48.

Type of men needed

“We went for volunteers because we wanted people who had specialized experience and a particular desire for this type of assignment,” noted Major Robert Bailey, public information officer for the Louisville Fire Department. “We knew from the beginning the effort would require a lot of training, a great deal of time, rather significant involvement, and a high level of interest. We tried to explain this right up front to candidates. Those who were selected jumped right in and did a hell of a job.

“Like a number of departments around the country, we in Louisville found ourselves faced with an increasing number of hazardous material and chemical incidents,” explained Bailey. “We realized that under the system we had been using—a one-vehicle chemical company—anytime it was dispatched, we had to designate an engine company to support it. We were looking for a way to modernize our hazardous materials incident response.”

“We respond throughout the city as a hazardous materials team, but cover just our stationhouse area as a regular engine company,” added Captain Tom Sheehan, a platoon commander for Engine 15. “If we are on a structural fire call and receive a hazardous material alarm, we leave two men on the pumper, supported by other engine companies, and four of us respond to the hazardous materials incident with the chemical unit. Probably 98 percent of the time, the engine and the chemical unit respond together to a hazardous materials call. The few times the engine has been tied up at a structural fire, the chemical unit responded by itself while another company was designated to support it at the incident scene.”

During the last 12 months, in addition to normal fire suppression calls, the team has handled approximately 25 incidents plus a number of runs that turned out to be false alarms or did not involve a hazardous material. There have been a half dozen train derailments with various commodities, including two with acrylonitrile. A wrecked and ruptured gasoline tank truck, a horizontal storage tank of no. 6 fuel oil on fire at the dome area, and a paint fire in a metal finishing plant were among recent incidents.

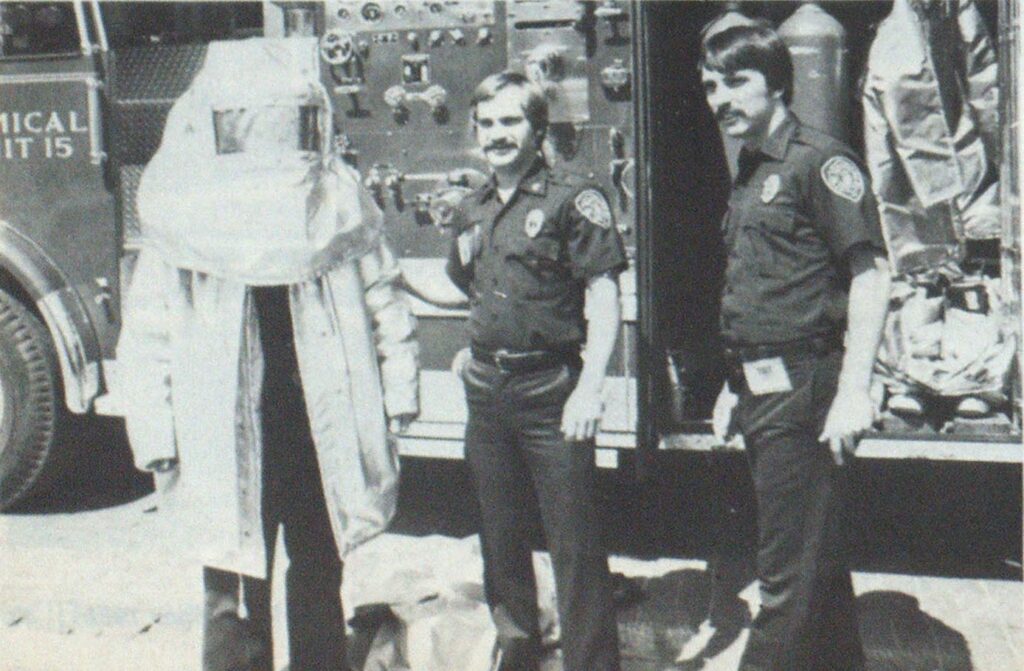

Photo by John R. Cashman

The team uses a command post style of operation. It uses perimeter tapes to seal off a work area and allows access to an incident site only to persons who have an absolute need to be there.

The team’s chemical apparatus carries a variety of response equipment normally available from commercial suppliers, such as proximity suits, acid-gas-entry suits, self-contained breathing apparatus, and explosimeters; as well as three 150-pound, wheeled extinguishers of dry chemical, Metal-X, and CO2 that can be accessed from drop ramps at the rear of the apparatus.

Lot of scrounging

In addition, the team did a lot of scrounging.

“We have a collection of plugs and clamps, plus pipeline caps from 1Vi -inch to 3 1/2-inch that we put together ourselves,” Sheehan said. “We also carry duct seal and large blocks of putty-like material that will patch a variety of containers. For a while, we were pretty regular visitors at plumbing supply houses and hardware stores.”

“Much of our equipment selection resulted from plain, old common sense,” said Bailey. “Out on inspections, we often obtained what we might need by procuring it from the industry we were visiting. Local industry has been very good about helping us stock up with what we need.”

Louisville team members say they have never yet seen a list of items that might be needed by the “average” hazardous materials response team because each locale is going to have different commodities and different containers unique to that locale. They feel something used regularly in another town might not be needed in Louisville. A tool or device they use all the time might sit on the truck in another locale.

The team uses experience gained through preplanning and actual incidents to guide their selection of response equipment and materials to ensure that the limited space on the apparatus contains only equipment for which there is a proven need. In addition, the team periodically reevaluates materials stored on the apparatus to determine if it has earned the space it occupies.

Target hazard program

“The department has had a target hazard program in effect for about eight years now,” Bailey stated. “We identify and preplan any building or complex we feel needs special attention.” Target hazard booklets for facilities handling hazardous materials are routinely made available to Engine 15. Also, the team is encouraged to inspect citywide any industry and any facility it deems necessary, and all files developed by other companies that might be of interest to the team are made available.”

Training is a continuous routine for the Louisville team. In addition to training in hazardous materials control and response provided by the department’s training bureau, individual team members regularly attend seminars, training programs, and classes throughout the country—as many as the budget will allow. As an example, a number of team personnel have journeyed to Florida to work and study with the hazardous materials team of the Jacksonville Fire Department.

“Money is a problem in any fire department,” emphasized Sheehan. “By utilizing a regular engine company for hazardous materials response, we feel we are getting maximum usage of personnel and equipment. We don’t have these men sitting around the stationhouse waiting for a hazardous materials incident that might occur twice a month. They cover a regular fire suppression response area but are free at a moment’s notice to break away and respond to a hazardous materials incident. They are a regular, on-line fire company, but trained and teamed to handle hazardous materials incidents citywide as needed.”

Indentification vital

When asked his opinion as to the most critical aspect of incident response, Sheehan replied without a moment’s hesitation, “Positive identification of the product. Until you get that waybill or shipping paper in your hand, you can hear all kinds of stories from people on the scene as to what the product in question might be. People want to be helpful in providing information, but they can unintentionally mislead you.

“When everybody at an incident location is suddenly placed under great stress and strain, the captain continued, “they may volunteer information that is far from correct. We make every possible effort to get that waybill, get that bill of lading, get hold of that piece of paper to be sure of what we are dealing with. Oftentimes, industrial or transportation people will have only a rough idea of what is in a container, or they may know but want to keep the situation very low-key.

“We have learned to get the waybill at all costs to obtain a positive identification,” Sheehan emphaiszed. “Then we use our manuals and reference materials to come up with the proper response and control techniques. We use all the well-known response manuals—NFPA, Coast Guard, DOT—possibly a half dozen. We often reference two or three different manuals to obtain the information we need to properly control a specific commodity. So far, we have been able to identify proper response and control procedures for each commodity we have been faced with, but we are quite cautious in making our initial identification of products.”

“Every day new chemicals are being developed and placed into the transportation stream,” Bailey remarked. “In some cases, the fire service has not kept abreast of the new chemicals and other materials added over the years. We may not be able to handle any situation that arises, but we are a heck of a lot better prepared than we were a year ago. There are definitely areas we can improve upon, but at least we have realized that we are faced with a problem area that is growing every day. A year from now, the problem will be worse than it is today.

“In Louisville, we have managed to achieve a bit of a head start,” Bailey said, “but three years from now we had better be even further down the road to hazardous materials preparedness.”