International Hazardous Material Training

TRAINING

Photo by Keith Weisgerber

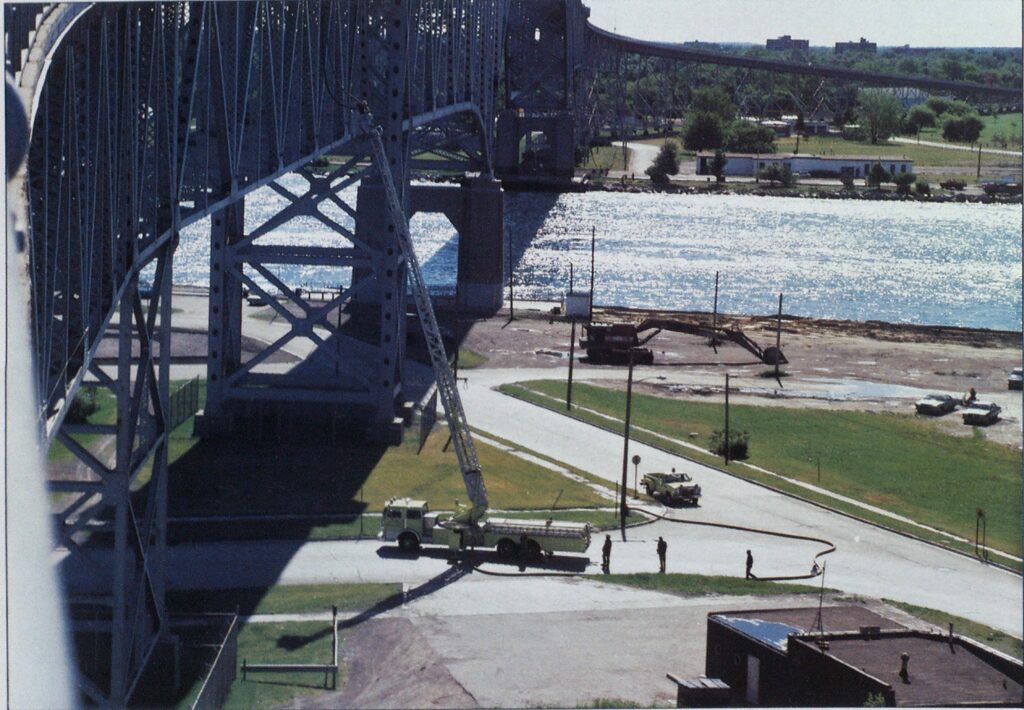

A tanker truck loaded with toluene is en route from Canada to the United States via the Blue Water Bridge. Before reaching the center of the bridge, the driver notices a sudden loss of air pressure. At this point, he knows that he has to stop the truck. He glances at the north side guard rail and then travels across the eastbound traffic lane, striking the south side guard rail, which brings his truck to a sudden stop.

The driver is not injured and exits the cab. It is then that he notices the puncture in the tank and the toluene that is flowing from it and traveling down the eastbound lane into the plaza area on the Michigan side of the bridge. A passerby alerts United States Customs personnel who, in turn, notify the Port Huron, MI, Fire and Police Departments.

The beginning of a potential disaster? Perhaps. But the incident depicted above never really happened. However, such an incident could very possibly occur anytime, day or night. This prompted the Port Huron Fire Department and the Point Edward and Sarnia, Ontario, Canada, Fire Departments to work together on an intensive training drill.

The assimilation was part of a drill executed on May 21, 1985, under the direction of the Port Huron Fire Department Assistant Chief Charles Nelson. If a similar hazardous material accident happened today, Chief Nelson believes his department would be much better prepared to cope with such an emergency.

BACKGROUND

The Blue Water Bridge, constructed in the 1930s, spans the St. Clair River, connecting Port Huron with Point Edward. The bridge provides highway access for the international point of entry into the United States and Canada.

According to Chief Nelson, “Since its construction, no serious attempt has ever been made to determine the consequence of a possible accident, such as this. The fire departments involved had no idea if water could be supplied to the middle of the bridge structure. With the increasing transportation and variety of hazardous materials crossing the bridge daily, firefighters would need a limitless supply of water. Our fire apparatus carry an average of 500 gallons of water, which is fine for vehicle fires, small incidents, etc. But, if a potentially disasterous situation such as this became a reality, we couldn’t begin to control or contain the problem. This was my primary objective in conducting the drill—determining our water capabilities.”

There is no water system on the bridge itself. The fire departments are dependent on relaying water from either end, using hydrants below the bridge and/or the river itself as a source of supply. With this in mind, Chief Nelson began to formulate emergency plans.

The primary bridge structure is as follows: There is 870 feet between main anchor piers, with two anchor arms, each approximately 330 feet long. The approach from the United States side is 2,300 feet, and from the Canadian side 2,660 feet. The bridge has no movable span, as 150-foot clearance above normal water levels is provided to vessels plying the shipping channels. The roadway is 30-feet wide and provides lanes for motor vehicle traffic. There is also a pedestrian walkway on the south side of the bridge.

Because the approach lengths are so long, laying supply lines from them to the middle of the bridge was assumed unrealistic. There were many problems involved in the organization and execution of such a drill.

Because the bridge is an international port of entry, the following departments and government agencies from both the United States and Canada became involved: the Port Huron Fire and Police Departments, the Sarnia Fire and Police Departments, the Point Edward Fire and Police Departments, United States Customs and Immigration, Canadian Customs and Immigration, the Blue Water Bridge Authority, the Port Huron Waste Water Treatment Plant, the Michigan Department of State Highways and Transportation, along with an international communications system. They all had common interests in the training exercises, and their consent and cooperation were necessary before a drill could be conducted.

Other areas taken into consideration prior to the drill included: water flow calculations, friction loss, apparatus setup, drafting possibilities, necessary manpower, etc. In addition, the bridge traffic would have to be halted for the initial setup, and then the eastbound lane into Canada would remain closed until the evolution was completed. This meant closing down an international border.

Undaunted by these obstacles, Chief Nelson and his department continued planning. He coordinated his efforts with Chief Steve Jay of the Point Edward Fire Department and Deputy Chief Jim Knight of the Sarnia Fire Department. There is an international mutual aid agreement between the three departments.

Research on the amount of hazardous materials that are transported across the bridge revealed the following results: Between the hours of 8 A.M. and 4 P.M. on a typical day in April 1985, 734 trucks crossed the bridge (either eastbound or westbound). Of these, 134 were placarded and contained hazardous materials. A random sampling included some of the following: gasoline, methyl ethyl ketone, liquid hydrogen, hydrochloric acid, propane, toluene, and anhydrous ammonia.

The closest alternate route is located in Detroit, 60 miles away. However, the crossing is privately regulated and does not allow the transport of hazardous materials across it. All placarded trucks attempting to cross are diverted to the Blue Water Bridge.

EXECUTION OF DRILL

After the government agencies in both countries granted their permission and the planning stage was completed, the drill commenced at 10 A.M. on May 21, 1985. The unique aspects of the plan included its handling of the international boundary problem and the solution it offered for delivering water to the bridge span (see diagram below).

The Port Huron Fire Department’s portion of the evolution atop the Bridge involved the response of five pieces of apparatus: a chief’s vehicle, three pumping engines, and an 85-foot Sutphin tower ladder equipped with a 1,500-gpm pump.

Chief Nelson performed the initial size up and determined that the strategic factor for the incident described would be the ability to develop a large caliber stream at the scene of the disaster. One engine was to respond to a location below the bridge ramp (at Gratiot Avenue) and take supply from a hydrant, previously tested at 3,900 gpm with 20 psi residual pressure.

Photo by Deborah Rietzler-Wager

The tower ladder also set up at that location and, at maximum extension, reached the roadway of the bridge. The dual deluge nozzles removed, the tower represented the water supply source from the hydrant to the bridge roadway.

Although the bucket level was 25 feet short of bridge access, two engine companies responding to the elevated location lowered two lengths of 2 1/2-inch hose. These were connected to each of the male outlets of the tower ladder.

The bridge crews connected a double 2 1/2-inch to 5-inch adapter (wye) and stretched 1,000 feet of 5-inch supply line toward the center of the ramp. (Each pumper laying their 500-foot complement in turn.)

This evolution permitted a pumping engine to receive an adequate water supply 200 feet from the incident at the center of the bridge span. The second engine layed two 272-inch lines to a 600-gpm deluge gun that would be used to mitigate the incident.

The total time that had lapsed from the dispatching of the units to the point at which an efficient large caliber stream was operating center span (1,300 feet from its supply) was 17 minutes.

The Canadian efforts produced similar results within the same time frame. The logistic and terrain problems on the Canadian side permitted them to use a more “basic” evolution, as can be seen from the diagram.

Due to problems encountered with supplying water 110 feet to the bridge deck and up the bridge grade another 60 feet, and through a total lay of over 1,000 feet, extensive hydraulic calculations were necessary. This was to ensure that engine company placement would provide adequate residual pressures, yet allow the pumps to operate at 100% efficiency.

Photos by Keith Weisgerber

RESULTS

Problems encountered

The following conditions had to be taken into consideration during the training drill: friction loss in the aerial tower standpipe, back pressure exerted in a 17-story lift, friction loss in hose lays, and minimum gallons per minute necessary to provide adequate fire scene attack. All of these details, planning, and hydraulic calculations proved to be correct. The evolution went off smoothly and as planned.

One problem was encountered with the kinking of the supply lines where they came up and over the bridge railings. These bends restricted the gallons per minute and affected discharge pressure. This problem was corrected by securing ropes to the hose and lifting them off the railings, which straightened out the bends.

Lessons learned

The primary recommendation that has been made as a result of this training is that a standpipe system should be installed on the bridge structure itself. This would solve the problem of relaying water from the street level.

During the evolution, water flow drainoff was monitored closely, as the bridge has scuppers along the roadway to allow for water runoff and drainage. These scuppers are closed off in the areas of the bridge approach that are over the streets, but not over the housing area. A hazardous material spill would run off into these areas, creating another problem. These areas of runoff were noted, and hopefully they will be dealt with sometime in the future.

The St. Clair River, a major link in the St. Lawrence Great Lakes Seaway System, has an average current of 7-9 mph. Because the cities along its course depend on it for their water supply, any hazardous material runoff that spilled directly off the bridge would affect their health and well being. Depending on conditions, the water treatment plants downstream might have to cease operation.

There is also heavy freighter traffic in this area. Boating, fishing, and recreational areas abound. All could be adversely affected by a hazardous material incident.

SUMMARY

As the result of the training drill on the Blue Water Bridge, a crisis such as this may be averted. Preplanning is essential when potential problem areas such as this are present in a community.

Chief Nelson commented on the results of the Blue Water Bridge exercise: “The training was a tremendous success. Everything went smoothly and was well organized. Now that we know what the effects of a spill and/or fire may be, we are much better prepared to handle one. Hopefully, we will never need to, but the seriousness of a potential disaster situation being created at anytime is now recognized by all.”