FARM EXTRICATION Rescue Technique Guidelines

RESCUE

Nationally, farm-work accidents claim it more than 1,800 lives annually and result in disabling injuries for 10 times that number of people. National statistics indicate huge losses from such accidents, and a recent University of Idaho survey showed that over a four-year period, rural accidents occurring in Idaho alone were responsible for 70 deaths and 70 injuries. What does this mean for the fire service? One more set of problems to overcome.

Rescue operations involving rural extrications are the most demanding of any in the emergency services. When an alarm sounds to signal a farm-work accident, details as to the type of machinery involved, the victim’s condition, and the accessibility to the situation are often sketchy. The response can be a long one: 20 miles of uneven roads to the farmer’s north section.

The initial response calls for your rescue/extrication unit with two men on board and an ambulance with two paramedics. Should you feel confident that you can adequately handle the incident? Absolutely not! Even though the responding men and equipment may be sufficient to handle many rescue situations, an incident without detailed information given on the initial response could result in disaster.

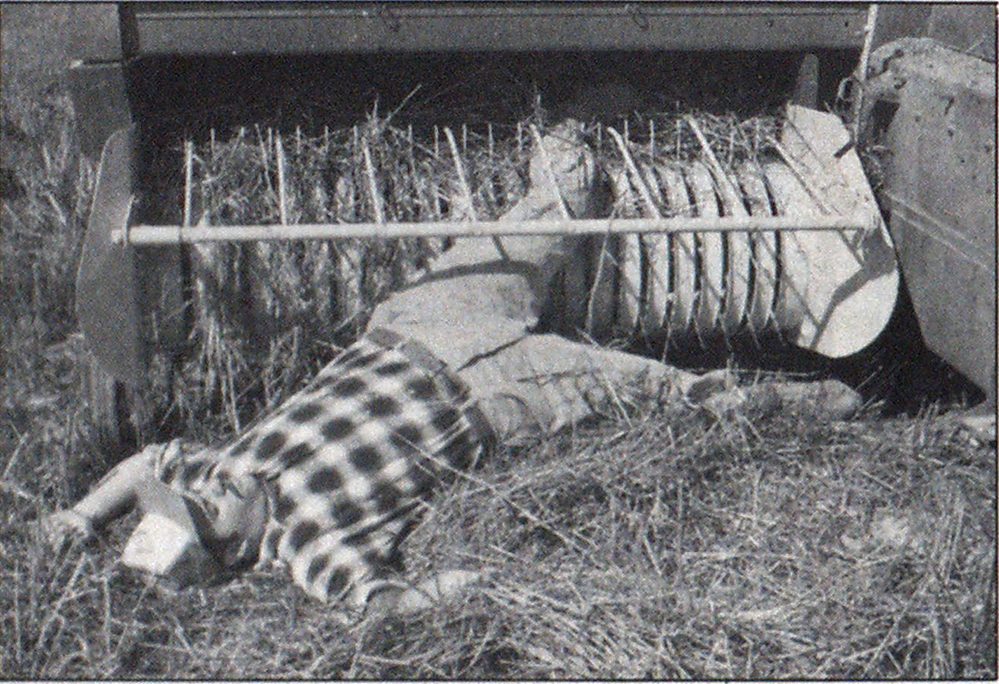

Photo courtesy of Pennsylvania State University

Handling emergencies in rural agricultural areas is difficult due to long response time, limited available rescue equipment, and an insufficient number of men to handle emergency apparatus. Conventional extrication equipment routinely used for removing trapped persons in auto wreckage prove either unsuitable or too light for effective extrication from farm machinery. The wide variety and intricacies of different models and types of heavy-duty machinery make standardized removal techniques impractical. The problem of long distance responses often results in serious injury or death for the trapped persons who can’t be reached in time to receive proper medical attention. Hilly or broken terrain also adds to the difficulties by creating dead zones for radio transmissions, making the ability to communicate for additional supplies or units poor.

Sound dismal? It should. However, proper preparation can overcome many of these problems. There are some guidelines that can aid in a smoother, more effective rescue operation even if you don’t have specialized equipment in your department.

The most important step in an effective farm rescue, especially if communication is expected to be poor, is to obtain as much pertinent information as possible on the original call to the dispatcher. It is always valuable to establish the specific type of machinery that is involved. The machine’s age, make, size, present disposition (overturned, collapsed, etc.), the portion that entraps the victim, etc., are essential.

This information is as important as the victim’s condition, as it will enable the rescue team to dispatch appropriate equipment (heavy wreckers, portable cutting tools, off-road vehicles, etc.) and save costly time, time that cannot be recovered after arrival.

If additional equipment is needed to make the rescue, it can very often be obtained from the victim himself, neighboring farmers, allied agencies, or local construction sites. It is also a good idea to keep a list of local dealers who handle various farm machinery in the dispatcher’s office. They may provide technical assistance if dismantling the machinery becomes necessary.

The on-scene setting will vary from emergency to emergency, but some common procedures will remain the same at all incidents:

- Life safety to the victim, by standers, and rescuers themselves is the primary concern. A hazard zone that encompasses the minimum number of necessary rescuers, and is off-limits to bystanders, should be established around the scene. If the extrication process is going to be lengthy, call for additional medical assistance.

Continued on page 72

Continued from page 68

- The machinery involved should be stabilized by cribbing, chocking, or shoring techniques, tying off to another vehicle, or some other measure to prevent additional injury. Most cultivated fields have unstable ground that can complicate matters by allowing the machinery to move in the soft footing during extrication procedures.

- Always anticipate the possibility of fire and have appropriate extinguishers or hose lines charged and manned! Large machinery have large fuel tanks containing gasoline, diesel, or LPG.

- Hydraulic fluid reservoirs are flammable and pose an additional threat of being stored under pressure. When heated, trapped fluid in hoses and cylinders can exceed pressures of 2,000 psi and rupture lines and tanks quite easily. Large amounts of spilled fluids can create a fire hazard; or if a rupture causes the fluid to be sprayed, open injuries are in danger of becoming burned and contaminated.

- Assume that any machinery involved in a situation is still running. Shut off all ignitions. Disconnect batteries. In the case of diesel engines, air intake ports may be blocked with rags to achieve the effect. This will eliminate all potential ignition sources and false starts of the machinery during rescue attempts.

- Have a selection of small hand tools such as wrenches, wedges, hammers, hacksaws, and bolt cutters. These are all that may be required to safely disentangle a victim from more complex machinery.

- The heavy construction of combines, balers, augers, and pickers under many circumstances will diminish the effectiveness of air chisels, most hydraulic jacks, etc. These tools still may be of some assistance in other situations, however, and should be made available just in case.

- Dismantling procedures, although time consuming, may be the only method available. If sufficient help is on the scene, executing more than one rescue procedure simultaneously may be considered, but only as long as one attempt will not interfere with the efforts of the other, and only when they both can be coordinated by a rescuer who will ensure their safety.

It is important to remember that farming accidents are unfortunate occurrences that will undoubtedly continue to happen. Effective dispatching and coordinated rescue efforts are the only tools on the side of the rescue services. Take note of your resources and pre-plan situational rescues so that you will be ready for those problems that lay ahead.

Penn State University Teaches Agricultural Rescue Procedures

Since 1978, Pennsylvania State University’s Department of Agricultural Engineering has been conducting a “Farm Accident Rescue” program throughout Pennsylvania.

During the first three years of the course, a lecture and workshop format was used. Slides from past agricultural safety programs were shown and divided into four areas; tractor rollovers, manure storages, grain-bin storages, and silos. The workshop also consisted of limited hands-on experiences using various farm tractors and pieces of equipment.

In 1981, Penn State’s College of Engineering instituted a new instructional development program. Videotape, supported by printed material, was selected as the effective medium for the new course. It would help solve the inadequacies of the old hands-on program, which included: 1) the difficulty of obtaining appropriate equipment; 2) the inability to disassemble or destroy equipment as in a real rescue; 3) a high turnover rate in the rescue service, which resulted in requests for repeat programs in the same geographic area; 4) the lack of qualified instructors; and 5) the need for more sophisticated instructional methods.

In the videotapes, rescue techniques are performed correctly and are supported by simultaneous on-camera explanations. Freeze-frame and voice-over commentaries are used to clarify activity that occurs too rapidly to be easily absorbed by students. Slides and overhead graphics are used to explain details that are not clear in videotape and in situations that would put rescuers or victims in unacceptably unsafe positions or operations.

Student workbooks are also used in the course. The workbooks are in outline form and allow the student to take notes. The most important feature is a listing of objectives for each lesson to help clarify the most significant points. Preand post-tests are developed for each topic. The testing helps to measure what the student has learned and allows for an evaluation of the course structure and content.

The program views agricultural accidents as a specialized area of rescue. A prerequisite for the course is a knowledge and understanding of basic rescue practices and skills; that is, the student should be familiar with rescue terminology, basic first aid, rescue philosophy, how to use rescue tools, etc.

Hands-on experiences with tractors, machinery, and farm structures are not required for certification. However, it is highly recommended that ail programs have some field experiences whenever possible. Other programs offered by Penn State include field experience with tractors, typical farm machinery, silos, and grain storages.

Field experience helps to reinforce the information presented by the videotapes and lectures. These include: 1) a general “walk around” with explanations of farm structures and machinery; 2) simulating entrapments and rescue from specific machinery and structures without major disassembly or destruction; or 3) full-scale simulation with old equipment and structures that can be torn apart or destroyed. The type of field experience possible depends on the number of instructors, the availability of farm machinery, and the size of the class.

For additional information concerning this program, Pennsylvania residents should contact William L. Sipple, 306 Agricultural Administration Building, University Park, PA 16802.

Dennis J. Murphy Extension Safety Specialist Pennsylvania State University