Controlling Hazardous Material Spills

features

There has been a heightened interest in recent years in the control of hazardous materials spills. Not only is life safety a concern of fire service personnel, hut protection of the environment is also of prime importance. Spills of hazardous materials must therefore be controlled and it usually falls to the fire service to either accomplish this or at least coordinate it.

The first step in controlling a spill of a hazardous material is to identify the product. The basic ways to accomplish this are through the use of:

- Placards,

- Shipping and/or transporting documents and

- Reference sources.

By federal law, vehicles transporting hazardous materials must be identified on four opposing exterior sides by placards. These placards identify the broad category to which the material belongs. Such chemical properties as corrosives, poison gas, poisons, oxidizers, explosives or radioactive are named.

Vehicles without placards

However, it is important to point out that under certain circumstances there will be no placard. If the amount of most hazardous materials is less than 1000 pounds in the transporting vehicle, no placards are required. The only exceptions to this are a poison gas, some radioactive materials and some explosives. In addition, only specific chemicals listed by the Department of Transportation (DOT) must be placarded. This means, for example, that some pesticides which are poisonous to human beings could be shipped without any indication on the outside of the transporting vehicle.

Finally, the complexity of federal regulations and approved exceptions increase the likelihood that the placarding regulations will not be correctly applied. Fire service personnel must approach all vehicle incidents with caution until the exact contents have been determined.

Shipping papers for trucks are carried by the driver in the cab. The bills of lading will contain the names of all products carried on the truck as well as the amounts. If any material is classified as hazardous, some technique to call attention to this fact is usually used. Some companies use a red and white border while others utilize large red dots. In any case, locate the papers as soon as possible.

On freight trains, the conductor usually carries the shipping papers in the caboose. However, they may sometimes be found in the engine. Called a waybill, train shipping papers contain the product name for each material carried. There is a single waybill for each freight car which makes up the train.

Waybill has car number

When an accident involving a train occurs, fire service personnel must obtain the shipping documents for all affected cars. The waybill will contain the specific car serial numbers. So fire service personnel must obtain these numbers from the freight cars with the problem and then locate the corresponding waybills.

Again, as in the case of trucks, the shipping papers must he located as soon as possible. Since there will be a large number of documents to go through, time will be critical.

With the many thousands of commodities being shipped today, it is impossible for fire service personnel to know how to deal with them all. Therefore, reference sources must be utilized.

One of the best sources of information on a hazardous materials spill is as close as your telephone. By calling 800-424-9300 toll free, you can reach the Chemical Transportation Emergency Center, CHEMTREC. Here, 24 hours a day, seven days a week, a communicator is available to provide information on how to handle an incident. In addition, the communicator can contact a great many other resources. For example, the Pesticide Safety Team Network or the Chlorine Response Team can be activated. Using special contacts within many of the chemical companies, definite information can also be obtained.

Facts affecting decisions

Once you have identified the product and received advice on a course of action, you must now implement the recommendations. The incident commander’s decisions will be based on several immediate factors.

- Is the material burning or in danger of being ignited?

- Is it poisonous? What are the life safety considerations to the general public, emergency response personnel on the fringes of the incident, and the emergency response personnel who will actually attempt to control the incident?

- Is the special equipment needed to control the spill available? Are such things as entry suits, transfer pumps, storage tanks, diking material, and absorbent material available? Is the fire department prepared with sufficient quantities of foam? Is there a standard procedure for providing backup supplies?

- Has a plan been developed for working with outside agencies, such as the environmental protection agency, law enforcement agencies, civil defense, and heavy equipment operators? Has a plan for a command post been developed?

- What is the terrain where the incident occurred? Can advantage be taken of the ground formation? What are the disadvantages of the ground formation?

- What is the availability, source, amount, and setup time of the water supply? How much equipment will be needed to move it to the incident scene and is this equipment available?

- What would happen if the emergency response personnel did nothing? Is the risk to personnel greater than the risk of leaving the spill alone until experts with special knowledge and equipment arrive on the scene?

Once all these questions are answered, the incident can be brought under control. However, the job still isn’t finished. The final process involves the cleanup and restoration of the site. While many fire service administrators will argue that cleanup is someone else’s responsibility, the fact remains that if there is still a danger to life and property, the incident commander (usually the fire chief) is still responsible. While the actual workers can be supplied by the transportation company, the environmental protection agency and/or the chemical manufacturers, supervision and coordination must still be provided.

Liquid asphalt spill

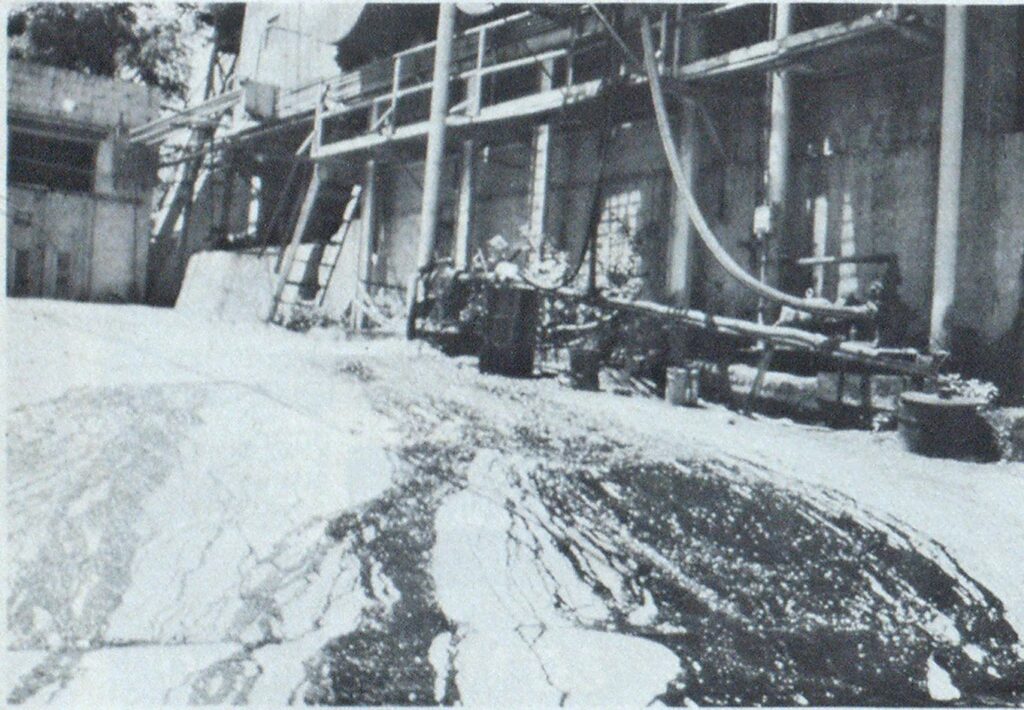

Montgomery County recntly experienced a liquid asphalt spill. Some individuals might immediately minimize the problems associated with this type of spill on the assumption that the only danger is to the environment. Unfortunately, an attitude of this type can really cause problems.

In this particular spill, the asphalt was a rapid-curing type with a flash point of 80°F. This clearly put the material in the DOT flammable liquid category.

In the early morning hours, a truck was filled with the asphalt from a storage tank. The valve was shut and the truck left the facility. Either the valve was not closed tight enough or it developed a leak. In any case, the material leaked from the tank for several hours before being discovered.

The storage tanks were elevated and located on top of a hill. Downhill about 200 yards was a stream which flowed in a southerly direction toward the Potomac River. The stream entered a tunnel about 1000 feet away and then passed under a railroad bridge which carries the main line of the B & O Railroad.

When the fire department was notified and arrived on the scene, the fire fighters saw the extent of the spill. The incident commander, Captain David Dennis of the Kensington Fire Department, ordered units to check downstream from the railroad bridge. These units found that the spill had just passed the bridge.

Two vital considerations

Two factors now became critical. All possible ignition sources had to be eliminated and the spill had to be contained before going farther downstream.

It was fortunate that this portion of the stream passed through an isolated area. The spill was located between the only two road crossings. With police assistance, access by the public was controlled and there were no other ignition sources in the area of the spill.

Containing the spill however, was not quite as easy. It was obvious that a dam had to be built to prevent the spill from going farther. Dennis requested that our special unit containing spill control equipment be dispatched.

On this special unit in addition to Light Water and Purple K is some special diking material. The equipment was manufactured by Mine Safety Appliance (MSA) and provided to Montgomery County for evaluation by the Federal Environmental Protection Agency in Edison, N. J.

The equipment consists of two chemicals in a backpack arrangement. When the pack is activated, the two chemicals are fed to a nozzle where they are mixed and then applied. As the mixture comes from the nozzle, it has the consistency of shaving cream. As the chemicals react, they expand and harden, forming a rigid barrier. One backpack will create about 25 cubic feet of finished product.

Leaves no residue

The final product will adhere to dirt and concrete. The adhesion capability will hold back the pressure developed by the static head of the liquid being contained. When cleanup is complete, the foam can be shoveled up and removed without leaving any residue. Thus, it is environmentally safe.

Most types of chemicals can be contained by the foam. However, it is itself flammable so that it cannot be used on a running spill fire.

In our particular spill, the foam was laid across the stream bed a layer at a time. As the foam expanded and hardened, the next layer was applied, increasing the height of the dam.

A second dam was built downstream about 500 feet as a precautionary measure. This was done to protect against t he first dam giving way and sending the asphalt downstream.

As soon as the dam was completed, the water backed up behind it. The next difficulty to overcome was to prevent the spill from overflowing the dam. Since asphalt has a lower density than water, it floats. Holes were made at the bottom of the dam to allow the clear water to continue downstream. These holes were enlarged so that the flow to the dam equalled the flow downstream and the water level remained constant.

The asphalt then accumulated behind the dam. Straw was placed on the upstream side of the dam to absorb some of the spilled material. In addition, absorbent material was spread on the surface of the stream to absorb the remainder of the spill.

Once all the asphalt was absorbed, the straw and absorbent were removed from the stream and hauled away by truck. The dams were picked up, leaving no damage to the stream bed.

For a hazardous materials spill to be successfully controlled, the fire department must be prepared in advance. The officers must know how to obtain information, what reference sources are available, where specialized equipment is located, and how to establish control of the incident. Only by being prepared can you expect a favorable outcome.

If the incident is handled this way, we probably won’t even read about it in the newspaper. However, if an error is made, the chances of the incident becoming spectacular are great and then we wll all know about it. Don’t be caught shorthanded. Plan your response now while you are not under pressure. Avoid the last minute rush which leads to newspaper headlines.

There are many reference texts available to fire service personnel which will provide information on specific chemicals. The names and addresses of suppliers of reference material are shown below. Prices are not shown because of the possibilities of changing costs.

National Fire Protection Association, 470 Atlantic Av., Boston, Mass. 02210:

Fire Protection Handbook Fire Officer’s Guide to Dangerous Chemicals

Fire Officer’s Guide to Emergency Action

Fire Protection Guide on Hazardous Materials

Hazardous Materials Slide Program

Glencoe, Press, 17337 Ventura Blvd., Encino, Calif. 91316:

Flammable Hazardous Materials Explosive and Toxic Hazardous Materials

Hazardous Materials Handbook

Bureau of Explosives, Association of American Railroads, 1920 L St., Washington D.C. 20036:

Emergency Handling of Hazardous Materials in Surface Transportation

Department of Transportation, Materials Transportation Bureau, Washington, D.C. 20590:

Emergency Services Guide for Selected Hazardous Materials Hazardous Materials Placards— Chart 3

Hazardous Materials Warning Labels—Chart 4

Labelmaster, 6001 N. Clark St., Chicago, Ill. 60660:

Hazardous Materials Commodity List

Maltese Enterprises, Inc. P. O. Box 34048, Indianapolis, Ind. 46234:

The Firefighter’s Handbook of Hazardous Materials

General American Transportation Corp., P. O. Box 532, Sharon, Pa. 16146:

Tank Car Manual

Manufacturing Chemists Association, Publications Service, 1825 Connecticut Av., N.W., Washington, D. C. 20009:

Chem-Card Manual

Cargo Information Card Manual

Agricultural Ammonia Institute Publications, 703 DuPont Building, 22 South Second St., Memphis, Tenn. 38103:

Operations Safety Manual for Anhydrous Ammonia Agricultural Ammonia Emergency

Chlorine Institute, Inc., 342 Madison Av., New York, N. Y. 10017: Chlorine Manual

Able Fire and Safety Equipment Co., Inc., 260 N. Fairfield, Chicago, Ill. 60612:

Dangerous Materials Emergency

Procedures Slide Rule

Railroad Systems and Management Association, 181 E. Lake Shore Drive, Chicago, Ill. 60611:

Chemical Transportation Safety Index

National Safety Council, 425 N. Michigan Ave., Chicago, Ill. 60611:

Chemical Safety Slide Rule

Fire Rescue Consultants, Inc., P. O. Box 5703, Rockville, Md. 20855: Identification of Hazardous Materials Slide Program Fire Instruction Research Enterprises, Inc., P. O. Box 357, Zelienople. Pa. 16063:

Fire Hazard Calculator

LP Gas Sales Department Phillips Petroleum Company, Bartlesville, Okla. 74003:

How to Handle LP-Gas Emergencies

Superintendent of Documents, U. S. Government Printing Office, Washington, D. C. 20402:

Chemical Data Guide for Bulk Shipment by Water, U.S. Coast Guard. DOT

Van Nostrand and Reinhold Co., Inc., 300 Pike St., Cincinnati, Ohio 54202:

Dangerous Properties of Industrial Materials, N. Irving Sax