By CALEB McNEIL

On January 16, 2017, construction workers arrived to investigate a section of a newly paved road on a quiet street in Key Largo, Florida. The workers had been asked to investigate a newly paved section of road that was not settling properly.

- What’s Your First Step in a Confined Space Rescue?

- Confined Space Rescue: Body Recovery vs. ‘Buddy’ Recovery

- Rigging for Horizontal and Vertical Confined Space Entry

- Confined Space Rescue: Hazards and Operations

One worker popped a manhole cover and climbed into a storm drain to see what was happening beneath the street. Soon thereafter, fellow workers realized their coworker had gone silent and attempted to call for him, but the man would not answer. One at a time, two other men entered the space, trying first to investigate and then save their unresponsive colleagues. All three men were quickly overcome by toxic gasses in the space.

Other frantic workers called 911, and the Key Largo Volunteer Fire Department was dispatched to the scene. On arrival, firefighters rushed into action, attempting to rescue the victims. One firefighter attempted to enter the space in his self-contained breathing apparatus (SCBA) but was unable to fit through the opening. The pack was removed, and the firefighter descended unprotected into the storm drain; within moments, he, too, became unresponsive at the bottom of the hole. A second firefighter, who was able to squeeze into the space with his SCBA, quickly packaged his fellow firefighter and, together, with those topside, performed emergency extrication of their fellow firefighter. Emergency medical attention was rendered on scene, and the first firefighter was airlifted to the hospital. With proper air monitoring, the presence of lethal levels of hydrogen sulfide and carbon monoxide was found within the space, and the scene was transitioned from a rescue to a recovery for the remaining patients. Three bodies were eventually recovered from the storm drain. The first firefighter survived his injuries.1

The incident in Key Largo is a classic example of how people are killed in confined spaces. The incident reveals patterns and confirms statistics well known to regulating and investigative bodies. Agencies such as the Occupational Safety and Health Administration (OSHA), National Fire Protection Association (NFPA), and National Institute for Occupational Safety and Health (NIOSH) have long known and taught about the dangers associated with these spaces and have created standards to deal with them. As a professional rescuer who will find yourself in and around confined spaces, it is imperative that you know and follow these regulations, too.

Following is a review of confined spaces and the regulations that govern the work done within them. As professional rescuers who may be called to do work in these spaces, it is vital that you understand these regulations. Some apply to you directly, while others teach critical lessons that will increase your understanding of the history, hazards, and risks of these spaces. Confined spaces are often deadly spaces; regulators have worked hard to create parameters that decrease the likelihood of you or your citizens succumbing to their dangers.

Early History of Confined Space Research

Following its creation in 1970, OSHA set about investigating leading causes of death and injury in American workplaces. Most of this work fell to NIOSH, the arm of OSHA responsible for investigation and research. As their studies developed and trends emerged, NIOSH instituted a program in 1982 known as the Fatality Accident Circumstances and Epidemiology (FACE). This study focused on deaths in the workplace and identified the following four categories of common deaths:

- Falls from elevation.

- Contact with electrical energy.

- Machine-related accidents.

- Entry into confined spaces.

From 1983-1993, the FACE study investigated 480 deaths stemming from 423 accidents. Of these deaths, 70 occurred in confined spaces involving the deaths of 109 workers.2 In addition to their FACE studies, NIOSH instituted the National Traumatic Occupational Fatalities (NTOF) surveillance system. Recognizing a gap in record keeping, the NTOF became the first national system to track workplace deaths.

From 1980-1989, the NTOF analyzed all death certificates involving workplace accidents. Through this study, NIOSH and the NTOF found an additional 585 deaths that had occurred in confined spaces with 670 victims.3 What was becoming clear to OSHA through NIOSH was that when workers entered these confined spaces, the risk of tragic death was an all-too-frequent outcome.

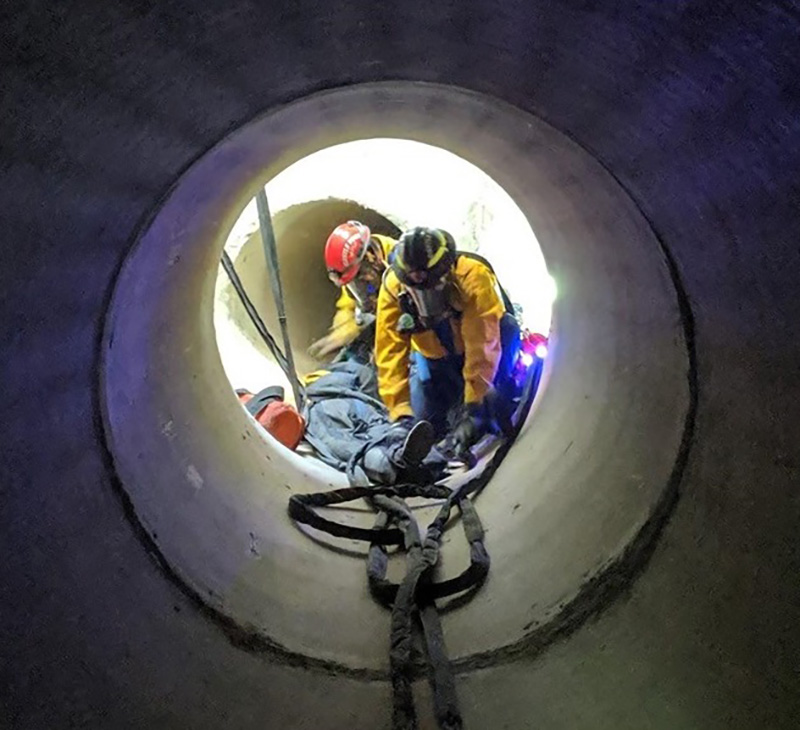

(1) A Castle Rock Fire & Rescue Department (CRFD) crew performs a confined space rescue drill in the storm drains in front of Fire Station 2. (Photos by author.)

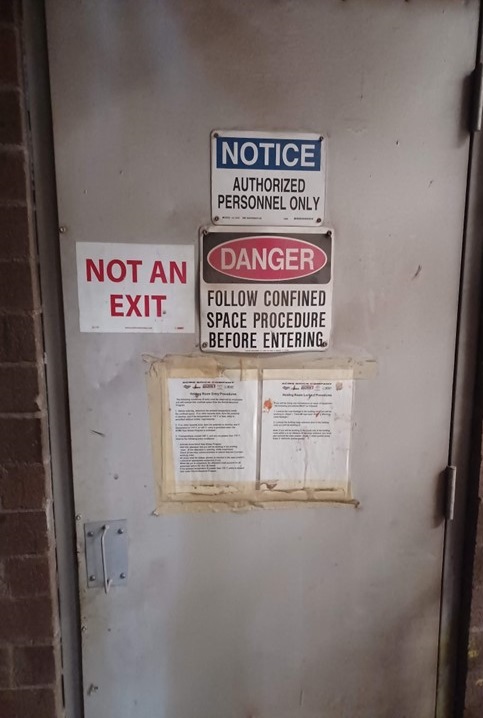

(2) Confined space markings on an entry door.

Accidents involving multiple victims. While looking through the data, NIOSH noticed some alarming trends. In both the FACE studies and NTOF analysis, an alarmingly high number of deaths involved more than one worker. Often, these additional deaths involved victims who entered the spaces following the identification of a problem, and they entered attempting to rescue the original victim but ended up succumbing to the same fate.

Workers lack training. Another theme in the studies was that workers seemed to be entering spaces unaware of the hazards posed. When training occurred, it most often involved only general workplace safety, rarely touching on the specific hazards posed by confined spaces. In the NTOF analysis of confined space deaths, only 6% of the workers involved had any specific confined space training.4 Often, they had received no training at all. Commensurate with this data was the lack of written policy or procedure for confined space entry by the companies employing the workers. When deaths occurred, lack of education, training, and planning seemed correlated.

Hazardous atmospheres and engulfment. The leading cause of death in both studies was hazardous atmospheres. Workers were entering spaces without recognizing the presence of an atmosphere that could kill them. These atmospheres could come in many forms; sometimes, the cause was a toxic gas present within the space, and other times it was simply a lack of oxygen. In the NTOF study involving 670 deaths, 40% (373) were because of atmospheric conditions and the most frequent location of these deaths was in tanks and sewage pipes.5

Following atmospheric hazards, engulfment was the next leading cause of death in the NTOF data. Engulfment happens when workers are overcome by the content of the spaces. The most common occurrence of these was in grain or other agricultural silos. Separate studies were done on trench cave-ins, which also accounted for many deaths involving engulfment. These trench incidents also displayed many of the patterns of confined space accidents but were classified separately.

Lack of emergency services. When emergencies happened, no plans or provisions were in place to deal with them. Not only did the companies lack written policies to guide the entry of these spaces, no one had planned on how to deal with the problems when they arose. When accidents happened, rescue services were too far away or nonexistent to do anything to affect the outcomes.

OSHA

This research led NIOSH to conclude that regulatory changes were needed. OSHA’s mission was to prevent worker injury and death, and these deaths were happening in preventable ways in confined spaces. In one publication released in 1986, NIOSH wrote the following:

“NIOSH investigations indicate that workers usually do not RECOGNIZE that they are working in a confined space and that they may encounter unforeseen hazards. TESTING and EVALUATION of the atmosphere are typically not initiated prior to entry and MONITORING is not performed during the confined space work procedures. RESCUE is seldom planned and usually consists of spontaneous reaction in an emergency situation.”6

OSHA 29 CFR 1910.146—the general industry standard. In 1993, OSHA compiled all its data into its first list of standards aimed specifically at the work performed in confined spaces by releasing 29 CFR 1910.146. Its goal was, “To protect employees in general industry from the hazards of entry into permit-required confined spaces.”7

With this standard, the first problem that OSHA tackled was the issue of recognition. Workers needed to recognize that entering a confined space posed unique risks, but no clear definition of confined spaces yet existed. To remedy this, OSHA created 1910.146, which says the following about a confined space:

- It is large enough and so configured that an employee can bodily enter and perform assigned work.

- It has limited or restricted means for entry or exit—e.g., tanks, vessels, silos, storage bins, hoppers, vaults, and pits, which are spaces that may have limited means of entry.

- It is not designed for continuous employee occupancy.8

When these three conditions are met, the location would be considered a confined space.

After recognizing that they were dealing with a unique space, OSHA needed workers to evaluate whether that space was hazardous. OSHA created two separate categories of spaces, ones that would not require permits and ones that would.

Evaluating: Non-Permit vs. Permit

Non-permit required. The first category was those that did not require a permit to enter them. These spaces “do not contain or, with respect to atmospheric hazards, have the potential to contain any hazard capable of causing death or serious physical harm.”9 Workers could enter these spaces without fear; thus, they did not need a permit.

(3) CRFD members attached to supplied air respirators package a dummy while training in the storm drains below Castle Rock. Supplied air systems located outside of the confined space allow members to operate for unlimited amounts of time without interruption in their air supply.

(4) CRFD crews train in a large confined space. Not all confined spaces involve tight working areas. OSHA’s definitions stipulate that only the entry/exit points need to be restricted to be considered “confined spaces.”

(5) CRFD’s technical rescue team performs a technician-level entry into a hopper filled with gypsum while training at a decommissioned brick factory. Any space involving any form of hazard should be considered a technician-level response.

Permit-required spaces. For those spaces that could or did contain hazards, a permit would be required. OSHA defined these spaces as the following:

- Contain or have the potential to contain a hazardous atmosphere,

- contain a material that has the potential for engulfing an entrant,

- have an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor that slopes downward and tapers to a smaller cross-section, or

- contain any other recognized serious safety or health hazard.10

Through 1910.146, OSHA required an employer to evaluate any space to which it would send its workers. If those spaces met the conditions of a permit-required space, they must clearly mark them as permitted spaces. Then, if the employer has determined that its employees would need to enter those spaces for any reason, it would need to develop and implement a written permit program. Prior to entering any of these spaces, a person aware of the hazards would create a plan to deal with those hazards, document all of this on the permit, and sign off on the entry. This permit would be kept at the location for the duration of the entry and remain available for anyone to reference.

Testing and Monitoring

After dealing with the problem of recognition, OSHA turned its attention to the issues of testing and monitoring. Deaths in confined spaces were happening when people did not recognize the hazards of the spaces they were entering. Through permits, OSHA hoped to stop the uneducated entry of spaces. If a space required a permit, 1910.146 required that certain things would be done prior to entry. First, employees would perform atmospheric testing of that space prior to entry (all permitted spaces would be tested): “Before an employee enters the space, the internal atmosphere shall be tested, with a calibrated direct-reading instrument, for oxygen content, for flammable gases and vapors, and for potential toxic air contaminants, in that order.” [1910.146(c)(5)(ii)(C)] If any of these things were outside of normal limits, workers would not be permitted to enter the space without further safety measures.

In addition to atmospheric monitoring, the spaces would be evaluated for other potential hazards such as engulfment or entrapment. When possible, these hazards should be eliminated prior to entry. This could be done through things like forced air ventilation, the removal of products, or the isolation of energy sources. The plan to deal with these hazards would be documented on the permit and signed off on by a qualified employee. Then the plan would be communicated and shown to the entrant. At no time would a worker be permitted to work in the presence of immediately dangerous to life or health conditions (IDLH). The monitoring of spaces would not end with the creation of a permit; periodic retesting would be required throughout the duration of the work being performed.

Training and Duties of Workers

1910.146’s subparts g and h also require employers who have employees entering permitted spaces to train their employees in the dangers of confined spaces and be knowledgeable on how to protect themselves. Each entry would require trained entrants, attendants, entry supervisors, and emergency service providers.

Entrants. An entrant is any worker who will be entering the space to perform work. These workers are knowledgeable of the hazards in the space and know how to detect them. They also know how to use the equipment for the work they will be performing. In the event of an emergency, entrants know how they will be notified and how to evacuate quickly.

Attendant. The attendant is a worker who remains at his post outside the space at all times. This worker’s primary duty is to monitor the space to ensure it remains safe for the workers inside. He does not participate in work that will distract him from his assigned duties; he is only permitted to enter a space to perform a rescue if he has been trained to do so. The attendant is responsible for maintaining communication with the workers inside and is familiar with the work being performed, the configuration of the space, and the hazards contained within. The attendant maintains constant monitoring of the space and is prepared to notify entrants when hazards are detected and work must cease.

Entry supervisor. The entry supervisor is the responsible party for each entry. This person is familiar with the space and the hazards that it may contain. He fills out the entry permit and creates a plan to deal with the hazards prior to entry. Once those hazards have been dealt with, he certifies acceptable entry conditions and then records his name and contact info on the permit and then ensures that the plan is understood by entrants and the attendant. Additionally, the entry supervisor creates a plan for emergency operations and makes sure the provider can respond within an acceptable time frame. Entry supervisors do not need to remain present on scene but, once work is completed, the entry supervisor will be responsible for terminating the permit and closing the space.

Emergency services. All permit-required spaces must have a designated emergency services provider. This provider is identified by the entry supervisor, who determines that he is qualified and prepared to handle the hazards of his space and can respond in a “timely manner,” which is a phrase that is often misunderstood; the intent is that the rescue service is close enough to effect a successful rescue from the known hazards. Rescue services must be knowledgeable about the configuration and hazards of the space and have the equipment and training needed to handle entry and rescue from the space. Although 911 is often the default service provider, in many cases, they do not meet the “timely manner” requirement and are often not familiar with the space prior to an emergency.

(6) CRFD members enter a vertically oriented confined space while using a tripod with a prebuilt 4:1 and lowering system.

(7) Aboveground confined spaces like this training prop at Texas A&M’s Extension Engineering campus pose unique challenges and hazards for personnel operating within them. Aboveground confined spaces are common throughout the country and likely exist within your jurisdiction.

OSHA 1910.146 Subparts

With its creation, OSHA 1910.146 became the governing standard for most workers in the United States. All employers and workers in “general industry” were expected to follow its precepts. Over the following 30 years, OSHA has continued to update and evaluate the effectiveness of this standard.

OSHA 29 CFR 1926, subpart AA (1200)—the construction standard. OSHA standards apply to only specific industries. For 20 years following the release of 1910.146, which applied to “general industry” and not construction, the construction industry remained without a confined space standard to govern it. However, confined spaces existed all over construction job sites, and workers continued to be hurt and killed.

In 2015, OSHA released 29 CFR 1926.1200 “Confined Spaces in Construction.” CFR 1926 had long existed as the OSHA standard for the construction industry but with the addition of 1200 OSHA dealt with how to guide the industry in confined spaces. In many ways, 1926.1200 mirrored 1910.146. It defined spaces the same way, required a permit program, and stressed the importance of evaluating and dealing with hazards. But unique challenges existed in construction that did not exist in general industry. In general industry OSHA could put the burden of responsibility on the employer; it was their job to analyze the work site. On construction sites, often multiple companies worked side by side. Who was responsible?

Competent persons and controlling contractors. OSHA 1926.1200 requires every contractor to designate a “competent person” to be in charge of the spaces on the job site. This person must understand what a confined space is and can determine whether it necessitates a permit. When multiple contractors exist on a job site, a “controlling contractor” would be designated. This controlling contractor acts as the entry supervisor and is the person responsible for creating a plan for entry, authorizing those plans, and keeping all those on the job site informed of them.

Air monitoring. Both OSHA 1910.146 and 1200 stress the importance of air monitoring, but 1200 takes things even further. Where 1910 requires the testing of three things (oxygen, flammability, and toxins), 1200 requires five, adding in combustible dust and any other IDLH hazard. Additionally, in the construction standard, OSHA states that “continuous air monitoring” should be done. This takes things a step further than 1910.146, which only requires periodic monitoring.

Early warning for engulfment hazards. The construction standard also added a provision not required by the general industry for engulfment hazards. When a potential for engulfment is present on a construction site, an early-warning system must be included and communicated to workers, allowing them time to exit the space. These hazards can include water, soil, or other products.11,12

NFPA

Although OSHA standards are directed at the safety of general U.S. workers and, in many cases, do not directly apply to emergency services, the NFPA exists for the specific purpose of “eliminating death, injury, property and economic loss due to fire, electrical and related hazards.”13 Like OSHA, it is a standard and code-creating organization. The codes that it creates are intended to prevent harm to both the general public and you, the firefighter.

Two standards were developed by the NFPA to deal specifically with technical rescue teams and individuals, which follow.

NFPA 2500—the search-and-rescue team standard. Originally published in 2004 as NFPA 1670, Standard on Operations and Training for Technical Search and Rescue Incidents, this standard was consolidated in 2022 with several other standards into the single standard of NFPA 2500, Standard for Operations and Training for Technical Search and Rescue Incidents and Life Safety Rope and Equipment for Emergency Services. In chapters 4-23, NFPA 2500 is still referred to as 1670, which addresses operations and training for technical search and rescue teams. NFPA 1670 provides guidance to the authority having jurisdiction (AHJ) to help it decide how to classify its team and how to train them accordingly. NFPA 1670 addresses seven different technical rescue disciplines, including confined spaces. As discussed above, OSHA requires that confined spaces have a designated rescue team. The NFPA fills in the gaps left by OSHA regarding what these teams should know and be capable of. In NFPA 1670, 4.2.1, the AHJ (rescue team) will be responsible for the following:

- Hazard identification.

- Risk assessment.

- Training level of personnel.

- Availability of internal and external resources.

To accomplish these things, the AHJ must know its needed response capabilities. For example, how complicated are the spaces the team will be entering? Once this has been assessed, the team will determine how to train for these responses. To determine the team’s needed training level, NFPA 1670, 4.2.4, breaks down team capabilities into the following three levels:

- Awareness.

- Operations.

- Technician.

(8) CRFD lowers a training dummy off a hopper silo while training at a decommissioned brick factory.

Awareness level. This is the minimum requirement for teams that have confined spaces in their jurisdiction. They identify confined spaces, know their hazards, and can summon the appropriate emergency response. These teams do not enter spaces to perform rescue.

Operations level. This level of provider understands everything that the awareness level does. However, these teams are allowed to enter and perform rescue in spaces that do not have hazards or potential for them. Operations-level personnel are also trained to assist with technical-level response.

Technician level. When spaces contain hazards such as physical, atmospheric, or engulfment, advanced technical rescue skills are required. Any emergency response to a space that has the potential or does include a hazard must utilize personnel trained to the technician level.

Once the AHJ determines what level it believes it should operate at, it can refer to NFPA 1670 to understand the specific qualifications its teams should have. These requirements include procedures, training, and equipment. As such, NFPA 2500, 4.2.11, states, “The AHJ shall provide for training in the responsibilities that are commensurate with operational capabilities of the organization.”

According to NFPA 2500, if your fire department responds to confined space incidents and will potentially enter a space that contains any hazard, it should operate at the technician level. Use it as a reference and guide in creating and maintaining your team.14

NFPA 1006—the search and rescue individual standard. Although NFPA 2500 deals with the technical rescue team, NFPA 1006, Standard for Technical Rescue Personnel Professional Qualifications, deals with the individual rescue technician. As a technician, what do you need to know to stay safe and be prepared? NFPA 1006 is only concerned with the technician; it defines nine different technician types (rope, trench, and so on), one of which is the confined space technician. Confined space rescue teams can use this as a guide for the specifics of what their individuals should be capable of performing.

NFPA 350. Twenty years after releasing the OSHA and NFPA standards, these organizations continued to gather data to see if the standards were working. This data indicated that confusion and misuse still existed surrounding confined space work. So, in 2015, NFPA released NFPA 350, Guide for Safe Confined Space Entry and Work, as a “guide for safe confined space entry and work.” This document explains how confined space work should be done instead of how it shall be done. It exists as a “how-to” document explaining how to safely perform the required things outlined in previous standards. The committee that created it targeted gaps that continued to lead to workplace incidents.15

All spaces receive a preentry evaluation. One of these gaps in was the confusion surrounding both non-permit- and permit-required entries. Confined spaces are not static spaces. A space that poses no risks to workers one day and can be classified as non-permit can change the next when workers enter to perform maintenance with chemicals or equipment, causing it to become a permit-required space. For workers and rescuers, this change is not always understood or communicated. Misunderstandings have led to complacency and confusion, leaving dangerous spaces unpermitted and unevaluated. NFPA 350 eliminates this confusion by referring to all spaces as “confined spaces” and requiring all of them to have an evaluation done before entry.

NFPA 350, 10.1.3.1 states the following: “The confined space rescue chapters of NFPA 1670 and 1006 consider all spaces to which they respond to possibly contain hazards. These standards make no delineation between confined spaces and permit-required confined spaces since an emergency involving a response has already occurred. These standards assume that a hazard may have caused this emergency, regardless of whether that is the case.”

If no hazards are found present or possible, then no additional paperwork would be necessary. If hazards are present/possible, the space is treated as a permit-required space, and plans should be put in place to deal with those hazards. For rescuers, like firefighters, this change is key; if summoned to a scene, they should assume that something has gone wrong. Every space at an emergency incident should receive a preentry evaluation prior to entry.

(9) Entry teams must wear personal protective equipment appropriate for the space they are entering. Supplied air systems should be considered a last line of defense.

Required Roles

NFPA 350 also adds supplemental information and roles for the rescue team from what is required by OSHA. In OSHA 1910.146, the duties of entry supervisor, entrant, attendant, and rescuer are required. NFPA 350 elaborates and adds to these roles for their purposes in rescue, which follows.

Rescue supervisor. This is the entry supervisor for the rescue. Like the entry supervisor, this member is responsible for the evaluation of the space and authorizes the plan for rescue.

Entry and backup teams. OSHA does not account for a backup team. NFPA 350 says that if a rescue is in progress, a backup team must be in place with equal preparation and training.

Attendant. Remains in place as required by OSHA.

Safety officer. This function is an addition to OSHA-required roles. The safety officer is an observer of the scene who understands potential hazards and is not a hands-on participator in the rescue.

Hazards

As identified by NIOSH and OSHA in the 1990s, confined spaces are uniquely dangerous. Proper evaluation of hazards prior to entry is paramount to the safety of workers and rescuers. NFPA 350, 6.3.4 asks for a broader evaluation than OSHA, stating that hazards can be inherent, introduced, or adjacent to the space. Not only can a space be dangerous because of what is inside it, but an evaluation of a space must also consider that the hazard may come from something outside of the space, like machinery operating in the vicinity, or be introduced, as would be the case when a welder enters to perform maintenance. Preentry evaluations must consider all these factors prior to entry.

Once identified, the work is not complete. Prior to entry, make every attempt to eliminate these hazards. This can be accomplished through a variety of ways such as lockout/tagout, ventilation, and removal of products. When you are unable to eliminate the hazards, entry can still be performed if proper steps are taken. NFPA 350, 8.3.1.5 states the following: “Personal protective equipment (PPE) provides a last line of defense to minimize the risk of exposure. It is the least desired control as it does not eliminate or reduce the hazard.”

(10) Technical rescue team members assist a teammate into a tight drainpipe. These situations pose unique challenges including the psychological condition of claustrophobia. Its risks should not be minimized while training or operating on the scene of a confined space.

Thirty years after OSHA released its first national standard dealing with confined spaces, people are still being hurt and killed in them. Statistical research by the U.S. Bureau of Labor Statistics spanning 2011 to 2018 shows that an average of 128 workers are still dying annually in confined space accidents.16 Workers continue to be hurt and killed in preventable accidents.17

Your job as a professional rescuer will be to respond appropriately when things go badly. In Key Largo in 2017, construction workers entered manholes without adequately considering the hazards that could exist in those spaces. One by one, the workers descended into the hole, succumbing to the deadly gases that had become trapped in its depths. Rescuers summoned to the scene failed to account for these hazards and nearly met the same fate.

As a professional rescuer, it is incumbent on you and your organization to ensure that you have the proper plans and procedures in place to deal with the dangers of confined spaces. The standards that have been written will aid you in these responses; they span more than 30 years of research into what is killing people in these spaces. The standards come directly from this research, creating rules to keep people safe when they descend into their depths. You are one of these people. When you understand and follow the intents of the standards, you provide everyone with the greatest chance of survival. Know the standards that govern the work you will be performing, evaluate and test every space prior to every entry, know the procedures of your organization, and be proficient in the equipment you will use. Ensure that when you arrive on the scene of a confined space you come as an educated professional ready to do your job.

Endnotes

1. Schmidt S. “One by One, 3 Utility Workers Descended into a Manhole. One by One, They Died.” The Washington Post, WP Company, 18 Jan. 2017, https://www.washingtonpost.com/news/morning-mix/wp/2017/01/18/three-utility-workers-descend-to-their-deaths-in-florida-manhole-overcome-by-fumes/.

2. Anthony SJ, et al. “Worker Deaths in Confined Spaces.” Centers for Disease Control and Prevention, Centers for Disease Control and Prevention, Jan. 1994, https://www.cdc.gov/niosh/docs/94-103/default.html.

3. Marsch S. “NTOF: Understanding Worker Deaths through Surveillance.” Centers for Disease Control and Prevention, Centers for Disease Control and Prevention, 26 Mar. 2021, https://blogs.cdc.gov/niosh-science-blog/2021/03/26/ntof/.

4. “Preventing Occupational Fatalities in Confined Spaces.” Centers for Disease Control and Prevention, Centers for Disease Control and Prevention, Jan. 1986, https://www.cdc.gov/niosh/docs/86-110/default.html.

5. U.S. Department of Labor. “1910.146 – Permit-required confined spaces | Occupational Safety and Health Administration.” OSHA, https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.146. Accessed 16 May 2023.

6. U.S. Department of Labor. “1926 Subpart AA – Confined Spaces in Construction | Occupational Safety and Health Administration.” OSHA, https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926SubpartAA. Accessed 16 May 2023.

7. MSA Safety Company. “Subpart AA: 1926.1200 – Confined Spaces in Construction.” https://f.hubspotusercontent10.net/hubfs/330211/Training%20Center/Training%20Center%20PDFs/OSHA%201926.1200%20Confined%20Spaces%20in%20Construction.pdf.

8. National Fire Protection Association. “NFPA overview.” https://www.nfpa.org/overview.

9. National Fire Protection Association. “NFPA 2500: Standard for Operations and Training for Technical Search and Rescue Incidents and Life Safety Rope and Equipment for Emergency Services.” NFPA, 2022, https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=2500.

10. National Fire Protection Association. NFPA 350: Guide for Safe Confined Space Entry and Work. NFPA, 2022, https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=350. Accessed 16 May 2023.

11. U.S. Bureau of Labor Statistics. “Fatal Occupational Injuries Involving Confined Spaces.” BLS, 15 July 2020, https://www.bls.gov/iif/factsheets/fatal-occupational-injuries-confined-spaces-2011-19.htm.

12. Carlsen C. “Confined Space Fatalities…an Updated Look at the Numbers.” Roco RescueTalk.™ Roco Rescue, 2 Sept. 2021. https://blog.rocorescue.com/roco-rescue-blog/confined-space-fatalities-an-updated-look-at-the-numbers.

13. Eady M. “The Rescue Tech and NFPA Standards.” The Rescue Technician and NFPA Standards, https://www.gpstc.org/wp-content/uploads/2013/06/gfa_resources_articles_rescue_tech_and_nfpa_standards.pdf.

14. “OSHA News Release—Region 4.” OSHA Investigation Finds Safety Failures Led to the Death of 3 Workers Who Entered a Manhole Containing Lethal Gases | Occupational Safety and Health Administration, 18 July 2017, https://www.osha.gov/news/newsreleases/region4/07182017.

15. Pettit TA, et al. “Working in Confined Spaces.” Centers for Disease Control and Prevention, US Department of Health, Education, and Welfare, Dec. 1979, https://www.cdc.gov/niosh/docs/80-106/default.html.

16. “Injuries, Illnesses, and Fatalities.” U.S. Bureau of Labor and Statistics (2020).

17. “Confined Space Fatalities…an updated look at the numbers.” ROCO Rescue (2021).

z

CALEB McNEIL is a firefighter/EMT with the Castle Rock (CO) Fire & Rescue Department (CRFD). He has a bachelor of science degree from Multnomah University in Portland, Oregon, and is a lead trainer and program manager for CRFD’s technical rescue team, specializing in rope and confined space rescue. McNeil is also a member of FEMA’s Colorado Task Force 1 as a rescue specialist.