Chemical Spill Spreads to Major Haz-Mat Incident

HAZARDOUS MATERIALS

Propylene oxide was in the process of being transferred from a railroad tank car into a 30,000-gallon underground tank at a transfer and storage point at Owens Corning Fiberglas plant in Newark, Ohio. A little after 11 p.m., a 15 X 30-foot spill was discovered in and around the transfer point and two adjacent, smaller spills were to the east.

At 11:10 p.m., the Newark Fire Department received a report of the chemical spill and immediately responded to the location. Identification of the chemical was made instantly by the placard on the tank car, causing the officer in charge to proceed with caution. Full protective fire clothing including Nomex hoods, SCBA and duct tape to seal all joints on the fire clothing were used in si/e-up.

Size-up

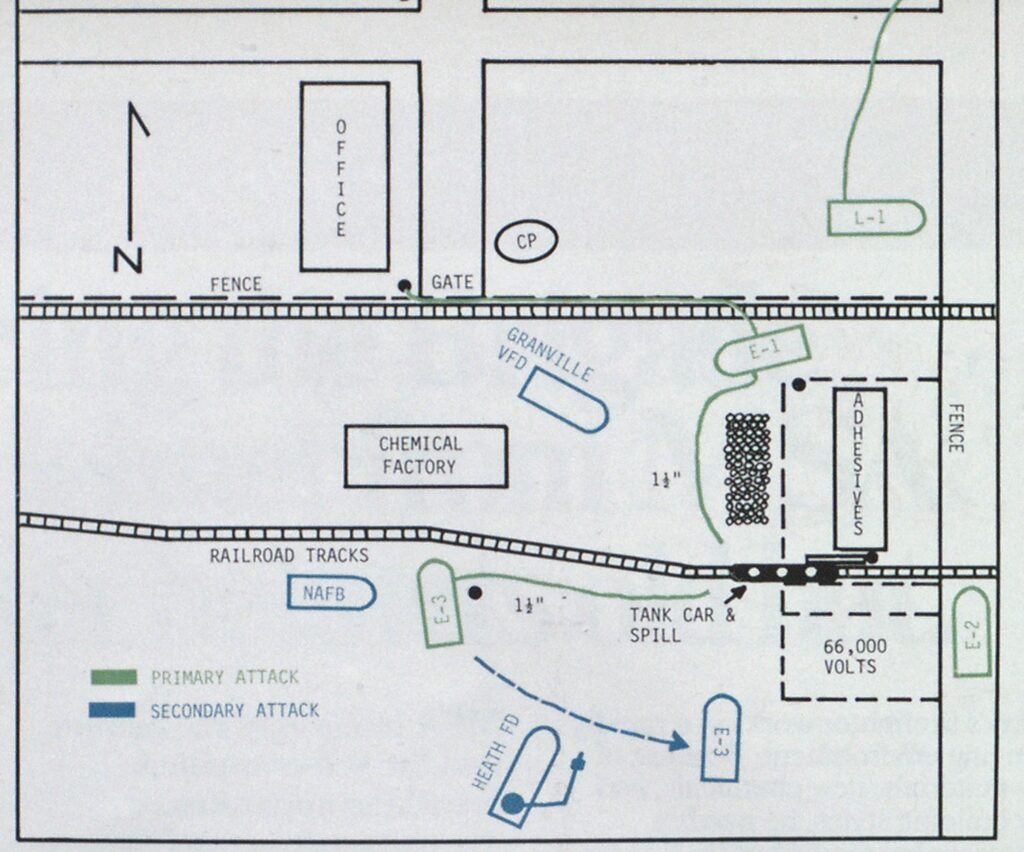

Minimum commitment of manpower necessary for a size-up of the situation was ordered by the commanding officer. A command post and staging area was immediately set up north of the spill. Natural boundaries—a fence, railroad tracks, storage areas and curbing— helped to define the hot (contaminated) zone. The National Weather Service was contacted to determine any changes in wind velocity and direction.

Two pumpers were positioned at hydrants located outside the hot zone, and two l/2-mch lines were stretched to protect fire fighters conducting a size-up within the hot zone itself. A ladder unit was positioned outside the fence as exposure protection if needed. The spill area was found to be surrounded by approximately 400 55-gallon drums containing traces of styrene, toluene, hexane, methyl ethyl ketone and diethvlamine. Five to 10 feet south of the spill was an adhesive plant and several aboveground tanks of unmarked solvent; a chemical factory and a 30,000-gallon tank of poisonous phenol was to the west; and a propane tank farm, storing approximately 300,000 gallons of liquid gas, was to the southeast.

When size-up was completed, the command post ordered the immediate evacuation of civilian personnel from buildings adjacent to the hot zone. The fire department life hazard in the hot zone was limited to a controlled number of personnel, and was physically assisted by a gate in the fence that defined the spill area. It was determined that anyone beyond the fence gate would be considered contaminated. Mutual-aid companies were radioed to respond with all available alcohol-type foam, carbon dioxide and dry chemical.

Preliminary containment efforts

The plant chemist, who was at the scene, was ordered to the command post for immediate consultation. Pending the arrival of the mutal-aid units with the necessary blanketing agents, the chemist suggested the use of the plant’s limited supply of inert absorbent pads.

The pads were used to line the edge of the spill area, preventing further spread. The supply was exhausted after accomplishing this. The chemist further suggested covering the spill with a pulverized clay material used as an oil residue absorbent. This was spread by hand dumping the bags on the spill area.

In the meantime, Newark police coordinated traffic control and evacuated not only the plant but 12 homes south of the incident. Ohio’s environmental protection agency and hazardous materials response teams arrived on the scene. The National Weather Service was again consulted for any changes in weather and wind conditions.

When the pulverized clay supply was exhausted, fire personnel were ordered to withdraw to await additional supplies and equipment. Moments after the clay material was spread, the spill area began to give off a thick, gray smoke. Hand lines were ordered abandoned and emergency personnel prepared for the possible use of master streams.

BLEVE

No sooner had this order been issued than the smoke gave way to ignition in the center of the spill. A small point of flame roared into a 100-foot fireball in a matter of seconds. The fire immediately exposed the 400 drums north of the spill.

Within five minutes, 12 55-gallon drums, believed to contain styrene residue, BLEVEd and rocketed over 200 feet in all directions, causing fire personnel to seek cover.

One engine was repositioned from the western side of the tank car to the southern side for its own protection and for more advantageous exposure stream penetration. A third engine to the east was ordered to apply a master stream to the tank car from that area. The ladder truck to the north was immediately fed by supply lines for additional coverage. This action allowed four master streams to supply about 600 gpm each at the flame impingement points on the tank car.

Another request for mutual aid was sent out as forces were not totally committed. All medic units in the county were requested to respond to the staging area set up to the north of the command post. All fire departments in the county were put on standby and, according to their mutual-aid contracts, some units began to move closer to the scene, filling in the gap in the central core created by this commitment of fire units.

Cascade systems to replenish SCBA cylinders were requested and responded from as far as 25 miles away.

Strategy and tactics

The strategy at this time was to allow the spill to consume itself in flames, and the main thrust of fire attacking forces was to keep the railroad tank car cool to prevent a disastrous BLEVE. The arrival of an additional engine and an elevating platform with large-caliber streams assured this strategy.

The fire darkened down in the area of the 400 drums, and with the arrival of supplies of foam, via an air base pumper, the command post ordered the drum area to be blanketed by two foam hand lines. The cooling lines on the tank car were ordered shut down and the two lV2-inch foam lines were then ordered to extinguish any fires remaining on the scene.

After consultation with the Ohio state hazardous materials unit, plant personnel cleaned up the spill area, protected by the two P/rinch foam lines.

Propylene oxide, a highly flammable liquid monomer, is colorless and moderately toxic when inhaled, ingested or absorbed through the skin. Its smell resembles ether. Propylene oxide is lighter than water and its vapor is twice as heavy as air.

Since propylene oxide is a polar solvent and miscible in water, alcohol-based foam, carbon dioxide or dry chemical is needed for fire extinguishment. With a flash point similar to gasoline, —35°F, propylene oxide reacts vigorously with oxidizing materials, and is highly dangerous and explosive when exposed to heat or flame.

photo by Timothy E. Black, “The Adi»ocatcS’cwark, Ohio.

Damage was kept to a minimum, and injuries were limited due to strict personnel control by the command post. The railroad car, though extensively damaged from the heat and flames, did not show any signs of leak or rupture.

Initial arriving fire forces and fire fighters operating in the hot zone were hosed down and had their clothing removed. At this time, 11 people exhibited signs of fume exposure. Headache, extreme tightness of the chest, nausea, dizziness, lightheadness and tingling sensations were experienced in varying degrees. Nine fire fighters, one police officer and one plant employee were taken by EMS personnel to the hospital for examination, treatment and observation. They were released later in the day. Many other fire fighters were treated at the scene and released.

The exact cause of the chemical ignition has not yet been determined. One theory is that the reaction of the clay material with the propylene oxide caused a violent buildup of heat energy. This theory, however, has been refuted by the plant’s chemist. The spill area had been a chemical transfer and storage point, and there exists the possibility of another chemical having reacted with the propylene oxide.

Pre-incident planning of pumper tactics and procedures in connection with the hazardous material problem coupled with the immediate control carried on by the hastily set-up command post prevented a potential disaster. Also, the cooperation of all departments and agencies contributed to a relatively smooth and controllable situation.

A major lesson was learned in the area of communications. Two-way communication between on-site fire fighters with their officers and the command post was extremely difficult due to the encapsulation of the fire fighters in protective gear and the restricted use of hand radios. Vital information had to be carried personally from the scene to the command post, causing exhaustion and sometimes premature removal of the SCBA facepiece in unsafe areas.

Another major lesson learned was the absolute necessity for a readily available listing of vital equipment, supplies and suppression mediums, noting their locations and quantities.