CHEMICAL DATA NOTEBOOK SERIES #78: PROPYLENE

HAZARDOUS MATERIALS

Propylene is a flammable, reactive, polymerizable, colorless gas that may have a faint, petroleum-like odor when pure. An odorant added to propylene makes it possible to determine whether propylene has been accidentally released at levels far below the lower flammable limit. Propylene is the monomer of polypropylene, and it also is used as a propellant in aerosol cans—usually as part of a mixture of other gases, such as propane, butane, butylene, isobutane, and isobutylene. Collectively, these gases usually are referred to as the liquefied petroleum gases, or LPG. Propylene also is used as a feedstock (raw material) to make many other chemicals, such as carbon tetrachloride, detergents, isopropanol (isopropyl alcohol), and propylene oxide. It usually is shipped and stored as a liquefied gas under its own pressure.

PROPERTIES

Propylene is a flammable gas. By definition, everyone realizes that flammable gases burn; but usually overlooked is the fact that the ignition mode of all flammable gases (and the vapors of all flammable and combustible liquids) is by explosion. This means that every time a flammable gas is ignited an explosion takes place. This is not obvious when a very small amount of the gas is ignited or if a larger amount of gas is ignited under controlled conditions, such as when a valve is opened and the gas is ignited immediately. A small explosion of natural gas or LPG can be witnessed when the gas in a burner on a stove or furnace is ignited. The implication is that whenever a flammable gas is allowed to accumulate, it explodes on ignition. The severity of the explosion depends on the amount of gas released (or accumulated), the size of the container or room, and the presence of the gas within its own flammable limits. The gas need not be confined to a container or room but may explode in the atmosphere as soon as it encounters an ignition source within its flammable limits.

Propylene has a flammable range (or flammable limits) of from 1.9 to 11.1 percent in air and an ignition temperature of 851°F. Gases technically have no flash points, but very often references will list a flash point for liquefied gases. For propylene, one reference lists its flash point as — I62°F. This means that for all practical purposes the ambient temperature always will be above the flash point of propylene—that is, at any temperature where man can exist, propylene always will be generating vapors sufficient to form an ignitable mixture with the air near the surface of the liquid. At all temperatures in environments in which you will be operating, every flammable liquefied gas exists at a temperature above its flash point. Therefore, the only thing needed for an explosion is the presence of a “suitable” ignition source. This is the main reason gases have no flash points: They are already in the form necessary to burn.

Liquefied propylene has a specific gravity of 0.61. Propylene’s molecular weight is 42, and its vapor density is 1.45. Its boiling point is — 539°F; it freezes at — 301.4°F, and it is not soluble in water. Its molecular formula is C*H(v

HAZARDS

Propylene’s biggest hazard is its flammability. Its low ignition temperature of 851°F can be reached by every common ignition source. Its lower flammable limit of 1.9 percent easily is reached in a leak or other accidental release. It is a short-chain hydrocarbon gas, and it burns in a manner similar to other short-chain hydrocarbon gases, such as methane, ethane, propane, butane, ethylene, butylene, and isobutylene.

Propylene is closest in chain length and molecular weight to propane; both compounds contain three carbon atoms. Propylene’s molecular weight is two atomic mass units (AMUs) less than propane, since propylene contains two fewer hydrogen atoms than propane. The major difference between the two compounds is that propylene contains one double covalent bond between two of its three carbon atoms (the presence of a multiple covalent bond makes propylene an unsaturated hydrocarbon), while propane contains all single bonds between its carbon atoms (a saturated hydrocarbon). The presence of this double bond between two carbon atoms creates a reactive site on the molecule—that is, the double bond, which contains more energy than the single bond, may be broken more easily, releasing its energy to the reaction, which speeds up the combustion reaction.

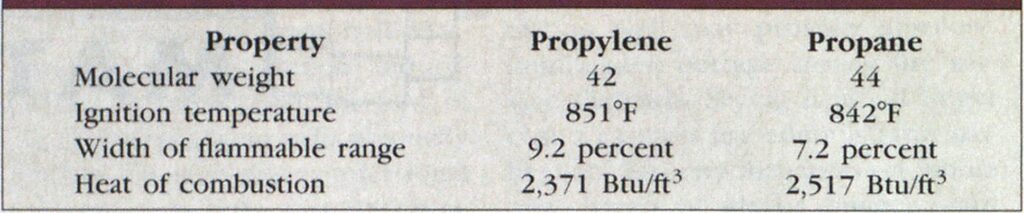

The presence of the double bond explains some of the differences between propane and propylene (see chart above).

Propane’s ignition temperature is slightly lower than that of propylene because of the presence of more fuel (two more atoms of hydrogen); propane’s heat of combustion is higher for the same reason. Propylene’s flammable range is wider because of the double bond —that is, it is more reactive than propane.

Propylene’s reactivity is another hazard. Although it is not considered an extremely reactive compound, the presence of the double bond makes it more reactive than saturated hydrocarbons. It reacts vigorously, even to the point of explosion, in the presence of strong oxidizing agents. It may react violently with halogens, strong acids, strong bases, and some halogenated hydrocarbons. It reacts with the nitrogen oxides to form explosive compounds.

Propylene is a simple asphyxiant, which means it is relatively nontoxic but will cause death as it lowers the amount of oxygen in the air. The National Fire Protection Association 704 marking system rates it as a “ 1 ” in the health quadrant, which indicates a low degree of irritation when it is inhaled or comes in contact with the skin. The skin can be damaged when it contacts liquefied gas. Since it has a boiling point of — 53 9°F, frostbite can occur. Most references list propylene as nontoxic and nonirritating.

As a monomer, propylene can polymerize to form polypropylene. When chemical engineers or other qualified personnel execute this reaction in a reactor under proper conditions, the polymerization occurs safely. The reaction is highly exothermic, so if the reaction occurs outside the reactor during an accidental release or during a period when the monomer is subjected to high heat or pressure, tremendous amounts of heat are generated. This speeds up the reaction (a rule of thumb in chemistry says that the speed of any chemical reaction will double with every 18°F rise in temperature) to the point where an explosion resembling a boiling liquid, expanding-vapor explosion (BLEVE)—known as a “runaway” or uncontrolled polymerization —will occur. The explosion may happen anytime a container of liquefied propylene (or any other monomer) is exposed to the heat of an approaching or impinging fire.

Monomers are shipped and stored with a material called an “inhibitor” or “stabilizer” added to it. This material inhibits, or prevents, premature polymerization. When the monomer is added to the polymerization reactor, an initiator, such as organic peroxide, is added to overcome the inhibitor and begin the polymerization reaction. If during storage or transportation the inhibitor is forced out of the monomer by being exposed to excessive heat or by the propylene being released from its container, runaway polymerization becomes a definite threat.

Some material safety data sheets indicate that polymerization will not occur. Since propylene is a monomer, always expect polymerization when there is a release or when propylene is exposed to excessive heat and/or pressure.

NONFIRE RELEASE

Since propylene is a nonpolluting material (the gas eventually will dissipate in air), many incident commanders may consider not including environmental experts in their list of resources for a release of this material. This is a mistake. They may come in handy to test water or to offer advice ^>n mitigation techniques, since they are knowledgeable in these matters. Also, an incident involving a hazardous material such as propylene triggers the community’s emergency response plan, and environmental authorities are required to respond when the plan is activated.

Evacuate downwind for from one to two miles because of the danger presented by movement of the gas. Evacuate around the container for a mile or more if a railcar or tank truck is involved. The threat of a BLEVE exists, and the destruction these explosions cause can be devastating to anyone nearby.

If liquid propylene has been released, it will begin to boil rapidly as it hits the ground or other objects. Once the liquid has pooled, however, it boils less rapidly, since the ground now will be supercooled and will not contribute much heat to the liquefied gas. Pushing diked walls up around the liquid, if possible, slows down the production of gas by keeping the liquid in one place. A containment pit is even better, since it provides less surface area to produce the gas. In addition, a smaller surface area can be more easily and effectively covered, slowing down evaporation. All tools and equipment used with propylene (or other flammable gases) must be nonsparking.

IDENTIFICATION NUMBERS AND RATINGS

CAS

(Chemical Abstract Services)

115-07-1

STCC

(Standard Transportation Commodity Code)

4905782, gas; 4905752, liquefied gas

RTECS

(Registry of Toxic Effects of Chemical Substances)

UC6740000

UN/NA

(United Nations/North America)

1077, propylene; 1075, LPG

CHRIS

(Chemical Hazard Response Information System) PPL

DOT

(U.S. Department of Transportation)

flammable gas, 2.1

NFPA 704 Rating

1-4-1

IMO

(International Maritime Organization)

2.1, flammable gas

Applying foam to the liquid’s surface may slow the evolution of vapors, even though initial contact by the foam may accelerate it. Reapplying the foam is necessary as the foam breaks down. If you dig a pit, use plastic or rubber sheeting to cover the surface. If you use this technique, be aware that the sheeting will get very brittle and may shatter if moved.

Prevent liquid propylene from entering storm or sanitary sewers. Damming or diking at entrances to these sewers diverts the liquid. Liquid entering a sewer vaporizes quickly as it flows, tilling the sewer with explosive gas. The explosion can take place at any opening along the sewer line and can result in localized explosions or an explosion of the entire sewer system. Notify all sewage-treatment facilities at once if any liquid enters the system.

Any liquid release can generate very large quantities of gas, and these vapors, being 1.45 times heavier than air, hug the ground and flow along low spots in the terrain unless dispersed by strong winds or a water fog or high-pressure spray. The same happens to gas being released from the container. A visible vapor cloud consisting of moisture condensed from the air by the escaping or evaporating cold gas may form. This cloud moves slowly downwind and shrinks as it moves as the moisture in the vapor cloud evaporates. The gas still is present even though the visible cloud has disappeared. If you use water fog or high-pressure spray to disperse the gas, do not let the water contact a pool of liquefied gas; it will increase the evolution of vapors. The moving gas may accumulate in low spaces or confined areas. More likely, the gas will move until it finds an ignition source; then it will explode and flash back to the gas source.

Liquid propylene entering a waterway will boil away rapidly, depending on the volume of water in the waterway and/or its movement. There may be some local freezing of water, but since propylene is not soluble in water, little harm should be done to waterfowl or aquatic life. If the banks of the waterway are steep and high, propylene gas may accumulate within those banks, presenting an explosive situation in addition to the dangers of asphyxiation posed to anyone without respiratory protection who is within the concentration of gas.

If you attempt to plug the leak in the container or to turn a valve to stop the flow of liquid or gas, wear the proper protective equipment. You need respiratory protection and nonpermeable clothing. Remember that all clothing and any plugging material become very brittle at the low temperature of the liquid or gas; they may fail with the slightest touch.

FIRE SCENARIO

If containers of propylene are threatened by the radiated heat of a fire or by impinging flames, withdraw all emergency responders; a BLEVE can occur. Cool the containers byapplying water with unmanned appliances from as far away as possible.

The proper way to extinguish a gas fire is to stop the flow of gas. Do not attempt to approach the container unless all threat of BLEVE has been removed. Do not try to extinguish the flame unless the flow of gas can be stopped immediately after the flame has been extinguished. Any flame from a leaking container that hits been accidentally extinguished may have to be deliberately ignited before the gas builds up enough to cause an explosion on reignition.

Carbon dioxide or dry chemical may be used to extinguish the flames from a small pool of liquid propylene. Beware of explosive reignition. It may be impossible (as well as unsafe) to extinguish the flames from a large pool of liquefied gas. You may have to allow the fuel to burn until it is totally consumed; be sure to protect all exposures. As always, the circumstances under which the release occurs dictate the mitigation techiques to be used; the protection of human life, of course, is the primary objective.

PROTECTIVE CLOTHING AND EQUIPMENT

Choose protective clothing and equipment that prevent liquid propylene from contacting the eyes or skin. Rubber or leather gloves, rubber aprons, and boots may offer skin protection; wear splashproof chemical goggles to protect the eyes. Use positive-pressure, self-contained breathing apparatus for respiratory protection. Be sure that all clothing is impervious to the liquid. Keep in mind that all clothing and equipment may become brittle and fail if they contact liquefied propylene.

FIRST AID

Inhalation. Move the victim to fresh air; keep him/her calm and warm. If the victim’s breathing stops or becomes labored, administer artificial respiration (such action might expose the first-aid giver to the material in the victim’s lungs and/or vomit). Seek immediate medical attention.

Eye contact. In the case of liquefied gas, flush the eyes immediately for at least 15 minutes, lifting the eyelids occasionally. Seek immediate medical attention.

Skin contact. In the case of liquefied gas, gently apply tepid (not hot) water to the affected body areas. Remove clothing carefully so that damage to frostbitten skin is not aggravated. Never rub frozen areas of skin.

Ingestion. It is highly unlikely that liquefied gas will be ingested. The mouth and esophagus would suffer severe damage from frostbite. Seek immediate medical attention.

SYNOHYMS

LPG

methylethene methylethylene NCI-c 50077 propene 1 -propene 1 -propylene