BY STEVE WHITE

Big truck accidents are similar to commercial fires in that they are low-frequency events. They require a different approach when it comes to personnel, tools, and tactics. To expand, fire departments respond to more single-family dwelling fires than commercial building fires, just as they respond to more vehicle accidents with entrapment involving passenger vehicles than big trucks.

Although basic functions for fire attack at residential and commercial fires such as applying water to extinguish the fire and ventilation to remove heat and smoke are common, particulars such as line size/length and tools used for ventilation and forcible entry will change. History has taught us not to take a residential fire mindset to a commercial building fire. For many firefighters, that can be difficult, as we go to more house fires. To break this mindset, we have to fall back on training and experience. When the majority of fire departments have limited fire duty, training has to be the key, and it’s certainly within our control.

Performing big truck extrication is no different. In big truck extrication, you can’t take a small -vehicle approach to a big-truck rescue. From staffing, staging, and vehicle size to tools, tactics, and construction, big truck extrication is considerably different from a tool job involving a passenger vehicle. It is also important to keep things as simple as possible so that the street firefighter can make smart decisions and easily recall important information for these low-frequency rescue events.

With rescuer safety being our number one priority, it is critical that the cargo always be identified prior to approach and starting operations. Follow local, state, and federal rules for hazardous materials identification and mitigation. Basic rules such as approaching uphill/up-wind, scanning the vehicle for placards, identifying the container type, and asking the driver what’s on the truck are safe and effective practices.

Standard rescuer personal protective equipment includes helmet, eye protection, ear protection (as needed), steel-toe boots, and work gloves. Structural firefighting gear or rescue gear is commonly worn for extrication. Flash resistive clothing with the ability to protect the rescuer from bloodborne pathogens is recommended.

For patient safety, hard and/or soft protection should be used to protect the patient. Hard protection could be a rigid material such as a pediatric backboard or a section of plexiglass. This is typically placed between the patient and a rescue tool operating in close proximity to the patient. Soft protection is a flame-resistant extrication blanket to shield the patient from debris such as glass.

There are three types of big trucks:

· Straight Trucks

o 25,000 to 40,000 lbs

Dump Truck Box Truck

· Semi Tractors

o 40,000 to 60,000 lbs

Over the Road Cab (with sleeper) Day Cab (without sleeper)

· Specialty Trucks

o Many moving and swinging parts

o Hydraulic lines and reservoirs

Garbage Truck Concrete Mixer

Big trucks are full-framed vehicles with two steel frame rails running from the front to the back; this is completely different from the unibody or space frames found in most passenger vehicles. Drive axels are at the rear of big trucks, not on the front axle.

Basic cab designs include cab-over (commonly referred to as “flat nosed”) and conventional (long-nosed”). Cab-over tractors are slowly disappearing from the roads, as the conventional cab is a smoother ride and easier for mechanics to work on.

Cab-over Conventional

Weight and height are instant challenges to rescuers when working with big trucks. Understanding weight is important to properly stabilize the truck. The legal maximum weight limit for an over-the-road truck is 80,000 lbs. They can be heavier, but must have a permit if they are above 80,000 lbs.

The windshield is laminated glass and typically held in place by a gasket. It can be removed by pulling the center bead of the gasket with a pair of pliers or small pry tool. Once the center bead is pulled, the gasket and windshield become loose, which allows the windshield to be removed as one piece. This reduces the small shards of glass and glass typically produced when using a standard window saw. A window saw can be used to cut the windshield, but the rescuer should avoid inhaling the glass dust.

Side and rear glass is typically tempered and can be removed with a standard window punch, but some trucks may have a polycarbonate type window, which is difficult to remove.

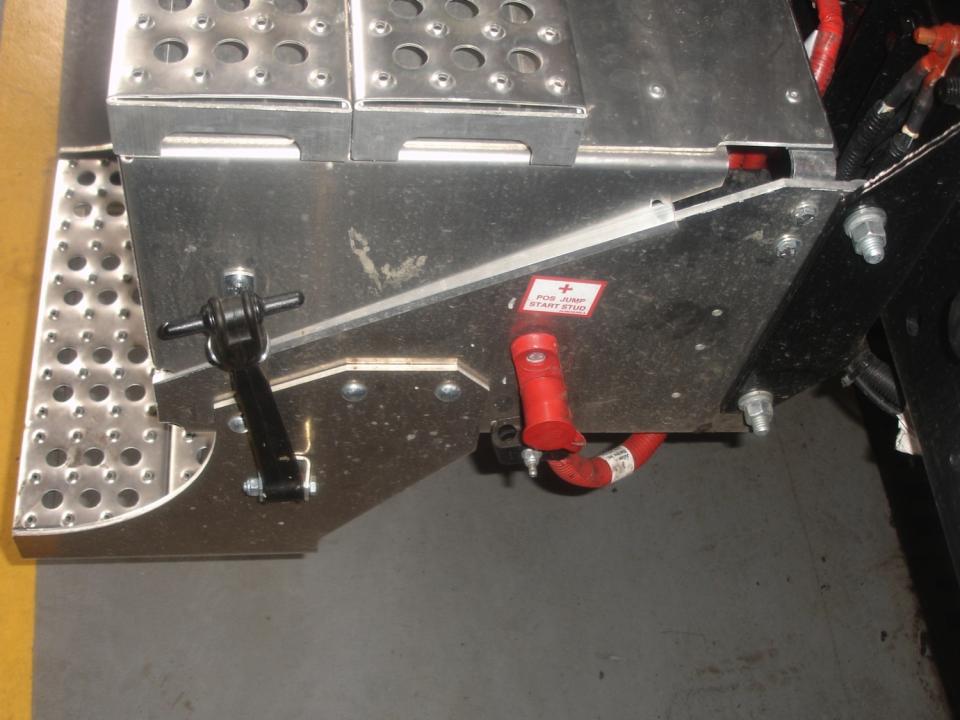

Locating the batteries can be challenging. Start with the driver side at the step used to get into the cab, then work your way toward the rear. Looking along the frame rail will typically lead you to the batteries. A box with big wires coming out of it or a red (positive) jump-post on the side of the box is what you will be looking for, particularly if the truck is on its side. Rubber “T” handle straps hold the battery cover in place.

A step that contains batteries. A step that contains batteries with a red jump post.

Fuel tanks are typically held in place by metal bands attached to the frame. For semi-cabs, there could be as much as 300 gallons of desiel fuel, mounted on both sides of the truck. During size-up, rescuers must pay close attention to the cap on the tank, as hydraulic oil is also store.

A standard diesel fuel tank.

Just after the front wheel is a diesel fuel tank; but just after the fuel tank is a separate (smaller) hydraulic tank.

Truck types and configurations will vary in each region of the United States. For example, rear discharge concrete mixers on a conventional chassis are common on the East Coast, and front discharge mixers on custom chassis are common in the Midwest. Rescue personnel should have a general working knowledge of the trucks commonly found in their response district.

Rescuers must know how to identify air-ride cabs and suspension systems, as well as air brakes for trucks, cabs, and trailers. Knowledge of these items will help reinforce proper stabilization. Stabilizing from the ground to the frame is essential, but the cab sitting on air-ride cushions must also be stabilized. This can be accomplished by wedging between the frame and the cab or using a buttress or strut system to stabilize the cab. The intent is that the cab is no longer resting on the cushions.

If rescuers can gain access to a semicab of a tractor-trailer, they should ensure the parking and trailer brakes are applied. The yellow knob is for the tractor; the red knob is for the trailer. Both are in the dash and must be pulled to apply the brakes.

Both knobs must be pulled to apply the braking systems.

To help rescuers overcome the challenge of height associated with large trucks, flatbed wreckers provide key advantages for increasing safety and operational effectiveness. When attacking doors or roofs, tools are now operated at the waist or chest level of the rescuer instead of at or above their shoulders. Patient packaging and removal are much easier, as the patient is brought onto the flatbed and then transferred to the ground.

Flatbed wreckers provide a stable platform for extrication and patient removal.

Door removal can be accomplished by attacking the Nader pin or hinge side of the door. When attacking the Nader pin, keep in mind that the pin is still in the center of the door, not at the bottom of the door where the door latch is located. Aerodynamic flanges after the door and grab handles will hinder placement of the spreaders. These obstacles must be removed if the hinge side should be attacked. For exterior piano hinges, an air chisel can easily cut the door from the A post.

Attempting a modified dash lift on a large truck is not a successful tactic for displacing the dash. For displacing the dash, using a standard dash-roll tactic is most successful, as the truck is a full- frame vehicle. This will require a section of the upper A post to be cut to not pull the roof down when pushing with the ram and a relief cut at the bottom of the A post.

A standard dash-roll tactic is used to displace the dash.

This article was intended to provide a basic overview of large truck extrication. Practical hands-on training reinforced by detailed classroom instruction is key components for preparing to respond and operate at a large truck accident. Rescuers must have a working knowledge of large truck weight, construction, hazards, and systems to stabilize, gain access, and perform extrication. You can’t take a small vehicle approach to a big truck rescue.

BIO

STEVE WHITE is a battalion chief and a 23-year veteran with the Fishers (IN) Fire Department. He is the team leader for the Hamilton County Technical Rescue Team and is co-chair of the Technical Rescue Section for the Indiana Fire Chiefs. He has served as an instructor for the FDIC heavy truck extrication H.O.T. program since 2007 and contributes articles and Training Minutes videos to the Fire Engineering Web site.