Steering Column Extrication: The Preparation

RESCUE

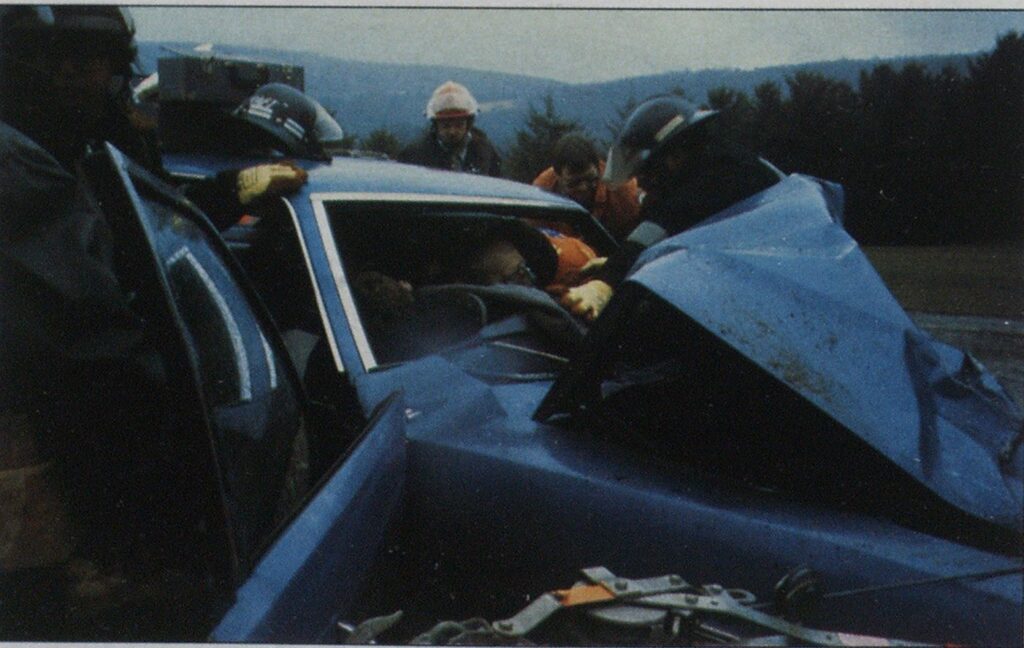

Four-wheel-drive has complicated vehicle rescue. This first of three articles shows where to start.

With front-wheel-drive automobiles now widely available, another new technology is challenging fire, rescue, and emergency medical personnel at the scene of motor vehicle accidents.

Front-wheel-drive vehicles have rack-and-pinion steering systems, in which the steering control arrangement is slightly different from that used by the more common rear-wheel-drive autos.

In the latter, a single, long column extends through the floorboards and into the engine compartment. But in the frontwheel-drive auto (see Figure 1 at right), the column is shorter, and the main shaft is really several sections joined together. The steering assembly typically consists of a two-piece shaft coupled by two universal joints, a jacket assembly, and a two-piece shroud. I call it a “split” steering column.

Photo by Ronald E. Moore

The universal joints that join the multisection steering column shafts together, typically flexible knuckle joints, are located inside the passenger compartment, either just under the dashboard or near the floorboard,

The same design may be found on some vehicles that don’t have front-wheel drive. The steering column of recent Volkswagon van models, for example, consists of four separate sections.

When it’s necessary, during a vehicle rescue operation, to move a split steering column away from trapped front-seat occupants, poor technique can actually make conditions worse for both the victims and the rescue personnel. But there are many acceptable rescue tool set-ups and methods for moving a column in a front-wheeldrive vehicle. Procedures can easily be modified so rescuers can safely and efficiently free a person trapped by a wheel and column.

We’ll examine five methods in the second and third installments in this series. In this first article, we’ll see why the split column presents a problem and cover some considerations that apply to all methods.

The most commonly used technique for moving any kind of steering column away from the driver’s area involves a pulling action. Accomplished with rescue tools such as air bags; hand-operated, ratcheted pulling mechanisms; and the spreader units of power rescue-tool systems, these procedures require equipment to be placed across the hood of the vehicle. With a firm anchor at the front of the damaged vehicle and a chain or strap secured to the steering column near the dashboard, this method has, until recent years, been relatively successful.

New problems

But because of the forces that rescue equipment operated in this horizontal pulling mode generate, rescue personnel are beginning to experience some problems moving the steering columns in frontwheel-drive vehicles. The effort produces a motion like that of a child’s seesaw. (See Figure 2.) The “action end” of the column—the end being pulled—moves up and away from the driver. At the same time, though, the “reaction end”—the portion nearest the floorboards—is lowered and may actually trap or further injure the vehicle’s driver.

The column can be pulled so far that the universal joint will fail and the column will snap in two. The free end will then launch itself into or onto the people inside the auto.

This danger isn’t unique to the split column. Experienced rescue personnel are aware of a similar fracturing potential with tilt-steering columns, which have been around for more than a decade. So if we’ve known about this same type problem for so long, why so much recent fuss about the columns on the front-wheel-drive cars?

If a column, even a split one, fractures, we have to assume somebody did something wrong.

More than likely, the rescuers became close-minded about what was going on around them. We refer to this failure to remain in touch with the overall situation as “tunnel vision.” Once emergency service personnel working at a rescue scene become swept up in the “emotion of the motion,” they may go too far. Rescue operations should do only what’s necessary to accomplish the task. When the desired movement is achieved, the task is complete. There are no extra-credit points given for “hotdogging” it! In vehicle rescue, an inch may be as good as a mile.

Another major reason for splitcolumn failure is wrapping the rescue chain or strap too high on the column. This pull near the top of the column exaggerates the unwanted seesaw action.

Try not to move

Whatever the cause, the seesaw effect will take place routinely long before the column is stressed to the fracture point. That means there are clues to be seen and time enough to compensate for any unwanted reaction. The clues include a crackling sound, visual signs of fatigue on the bottom side of the column, and movement of the dashboard toward the victim. If any of these things occurs, the column pull should be stopped and a different disentanglement procedure initiated.

The point here is that a column pull may still be feasible with fourwheel-drive cars if rescuers know what to do.

But before they use the column pull or any of the alternative methods for steering wheel extrication, rescuers should take routine safety precautions (see “Extrication Safety Checklist,” opposite) and perform a number of other tasks.

The first is size-up. Rescuers have to confirm that the patient is truly trapped. A close look might reveal that the wheel or column isn’t even touching the patient. Search out the possibility that the victim is pinned by other objects, such as the dashboard, gear shift levers, hand brake controls, or floor pedals.

When the steering wheel is actually contacting the patient, you must determine to what degree. An obese person’s belly may be wrapped over, under, and around the steering wheel, but not trapped. Search out by sight and touch the path that the arc of the steering wheel ring takes.

Collision damage to the front of the vehicle, serious deformation of the wheel, or obvious contact between the wheel and the patient indicates actual entrapment.

If there’s anything rescue personnel can do to avoid having to move the column, that possibility should be thoroughly investigated. For example, operating the control lever on a tilt-steering column may raise the upper steering column at the tilt joint enough to extricate the patient. Or if the force of the impact has slidden the driver’s seat into its forward-most position, disentanglement may be a simple matter of using manual or electric controls on the seat to quickly move it rearward.

As the list of simple solutions is run through item by item, the situation boils down to the fact that the patient may actually be trapped.

At this point, the initial size-up portion of this particular rescue job stops, and the second step begins: moving or removing the lower portion of the steering wheel and any supporting steering wheel spokes.

This cutting action should be performed anytime indications are that the column will in fact have to be moved, or else the victim could be further injured. Usually you’ll find that the column pivots and bends around some anchor point near the dashboard so that most movements of the steering column will cause the lower portion of the steering wheel to arc closer to the trapped driver before moving clear.

The typical steering wheel ring is constructed of a ⅜-inch round core of cold-rolled steel covered in plastic, vinyl, or some other trim material. Overall diameter of the ring is just about one inch. Larger vehicles generally have larger-diameter steering wheel rings constructed the same way.

The steering wheel ring should be moved or removed prior to any movement of the steering column. Movement involves a complete cut of the ring at the 9 o’clock position (from the driver’s point of view). Once the ring is cut through, its lower portion can be manually bent up and away from the driver, moving toward the driver’s right. This causes the ring to pivot and bend at the 3 o’clock position.

This relatively simple yet delicate task should give added clearance of 6 to 12 inches between the driver and the center portion of the steering wheel.

It’s more common, though, to cut away all or part of the wheel. Cuts can be made at the 3 o’clock and 9 o’clock positions to remove half of the ring.

Or you can cut all of the steering wheel support spokes near the steering column hub. These two or three cuts may allow for complete removal of the ring and the spokes in one action. This method depends on the positioning of the patient at the wheel. There may be very little working room inside the automobile, making the spoke cut impractical.

For cutting away the steering wheel ring, you can use such hand tools as a hacksaw with lubricating oil, 36-inch or larger bolt cutters, or a ratchet-type bolt cutter. Electric tools include a reciprocating saw (with adequate lubricating fluid) and the cutting units of power rescue systems.

You can use the same tools for cutting away the spokes. However, the bolt cutters and ratchet cutter may not work if the spokes are wide or extra thick.

The choice of primary and backup tools for cutting will depend on how much working room there is between the wheel and the patient in the driver’s seat, and how much time it takes to get certain tools into service. A hacksaw may be slow and crude, but it will finish the job long before bigger, more sophisticated tools can be set up.

A new size-up is needed to judge if column movement is still called for.

Once a portion of the steering wheel has been moved or removed, the trapped driver has additional clearance—and may even be free. A new size-up is necessary to determine if movement of the column is still called for. Remember our philosophy with this job: If there’s any way to get around moving the column, that’s what w_____ want.

If the driver is still trapped by the column, the decision now boils down to how to best move the column away from the driver. At this point, rescue personnel must again consider the type of auto, its location, and the extent of damage; positioning of the driver and all other occupants within the vehicle; and medical work that’s been done thus far or still needs to be done. The tools available for the task, both primary and back-up, must be thought of. Also consider what other rescue evolutions have been or need to be done.

With these things in mind, you’ll be able to choose among the five methods of column movement: pulling across the front, lifting across the front, working across the windshield, pushing from inside, and removing the column. We’ll examine each of these in detail in the second and third articles of the series.