Standpipe Operations

STRATEGY & TACTICS

More on High-Rise Tactics:

Guidelines that should be observed by

firefighters to achieve maximum effectiveness when operating lines from standpipe outlet connections and when supplying standpipe fire department connections.

Standpipe systems within tall or large-area structures are a vital resource for mounting an effective interior attack. Ensuring an adequate and reliable water supply is a primary objective whenever fire department operations require one or more handlines to be stretched from and supplied by the system.

- If it is determined through proper size-up considerations that a standpipe system will be used to supply the firefighting attack lines, the first engine company to arrive must connect to and supply the fire department connection (Siamese) that will supply water to the riser(s) from which those lines will be operated.

- After the first supply line is stretched, charged, and supplying the connection, ta second line should be stretched and ^charged to the same Siamese connection by that first-arriving pump operador.

- One of the next-arriving engine companies should supply an additional fire department connection (Siamese) that will augment, through cross-connection, the water supply system being used. This will assure that two pumping units are supplying the system from remote locations. It will assure adequate supply and establish a safety factor should water supply of one unit be ‘interrupted because of mechanical or equipment failure.

- When it is determined that handlines will be operated from a standpipe hose ^outlet connection, the supply pumper(s) ^ iamese connection at proper pressures shall charge the system through the (guidelines in Item 7). Care should betaken to increase pump pressure slowly to the required pressure to avoid surges that may damage the system or cause loss of nozzle control. When more than one pumping unit is supplying the system, operators should communicate to coordinate their pumping pressures.

- The pump operators must assure that water is actually being supplied to the system:

- If the pumper is equipped with flow gauges, they should be monitored constantly.

- Pump heat gauges should be monitored. Overheating indicates that the water in the pump is churning and no longer moving. Other indications of water flow:

- The metal cap on the large suction inlet can be monitored to determine its temperature. If it is cold and covered with condensation, water is flowing. If found to be warm to the touch, water is churning and being heated within the pump.

- One of the discharge gates that is supplying the Siamese can be shut down momentarily. If there is a corresponding increase in the pump pressure gauge or the tachometer reading, water is flowing. Conversely, if there is no change in the gauges, you have not interrupted flow and water is not being supplied to the standpipe system.

- If fire conditions are such that more than one handline is to be used, the system should be augmented by a second pumping unit. If an additional Siamese connection is not available, a supply line can be stretched to the outlet on the first floor of the structure and the system supplied from there. Connecting to and augmenting supply from the riser outlet will ensure water supply in event of problems at the Siamese connections or the check valves. In this case, you must have the ability to remove any pressure-reducing devices at that location before supply connections are made.

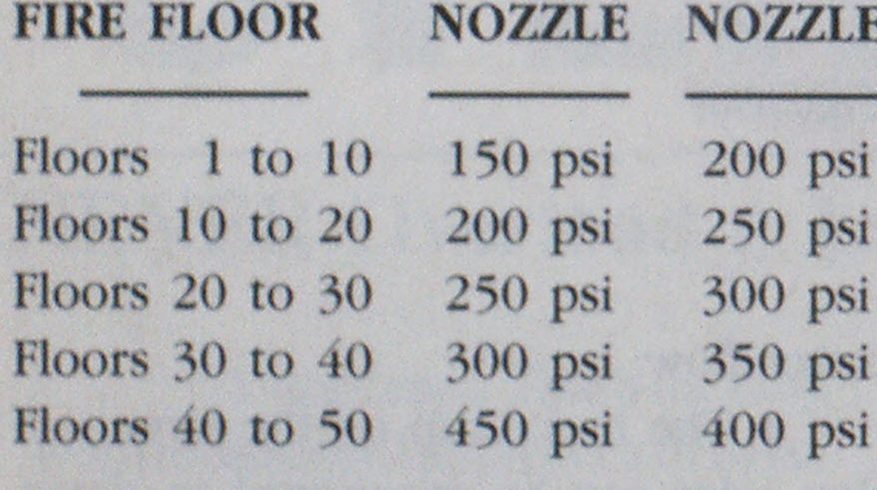

- To simplify or standardize pressure calculations required at standpipe operations, the following chart has been formulated. It accounts for required nozzle pressure, friction loss of three lengths of 2V.2-inch hose, head loss, system friction loss, and the friction loss of two lengths of V/2-inch hose used to supply the fire department Siamese connection.

- If the height of the fire floor requires pumping at high pressures (in excess of 250 psi). the following precautions should be followed:

- All personnel must be removed from an area 50 feet on either side of the supply lines stretched from the pumper to the building standpipe Siamese.

- Suitable warning tapes, stanchions, or utility ropes will clear this area and prevent possible injury should the hose burst.

- Supply lines for high-pressure pumping should be connected to gates opposite the control side of the pumper.

- Couplings should be secured to substantial objects by use of utility ropes or other fastening devices.

- Extra pump operators should be assigned to the high-pressure pumping units. They should maintain communications and relay orders to or from the operators of the pumps. Higher noise levels during this operation make normal communication procedures ineffective.

- If a fog nozzle is to be used on a line that will be operated from a standpipe hose outlet valve, the pump operator should be notified so that he can select the proper pump pressure.

- Relief valves on all pumpers supplying water to a standpipe system must be set.

- If the building is equipped with a sprinkler system, one of the first lines stretched should supply that system after the standpipe connection is supplied.

- If the building is equipped with a combination standpipe/sprinkler system, the pump operator must be aware that additional water may be required.

- If available, 3’/2-inch hose should be used to supply the water to the standpipe system. This hose is usually tested to 600 psi.

- Pump operators should know their pump capacities at all operating pressures. They should be alert to the number of lines being operated off the standpipe system and to additional demands that any sprinkler system may be making on the water supply. Before the demand reaches pumper capacity, he should alert the ofticer-in-command to the need for additional pumpers to augment the system.

- A company officer should be designated at the earliest stages of operation. His duties will include:

- verifying that the above items have been carried out:

- confirming that the proper pressures are being supplied:

- coordinating the pumping operations of the units supplying the standpipe system;

- ensuring that the building’s standpipe pumps are in operation, and coordinating their use and operating pressures with the operation of the fire department pumpers.

OPERATING A LINE

- When operating a fire department handline from a standpipe hose outlet, the pressure-reducing valve must be removed from the hose outlet valve before the hoseline is attached.

- The member operating the hose outlet valve should open it slowly to avoid a surge of pressure at the nozzle.

- The member operating the hose out-‘ let valve should open it sufficiently to’ obtain the required nozzle pressure. The officer in charge of the hoseline* should be responsible for communication with this member to obtain the correct pressure at the nozzle.

- When the nozzle is to be closed down, the officer in command of the” line must be aware that it may be necessarv to coordinate closing down .the hose outlet valve to prevent overpressurization and the possible burst of the hoseline if the pressure in the standpipe riser is above the operating pressure of the hose.

TYPICAL PRESSURE-REDUCING VALVES