Characteristics of Rope Materials

features

Fire service rope is often neglected until it is needed to raise ladders or to perform rescue work. Most of the rope’s life span is spent forgotten in an apparatus storage compartment or in the pocket of a fire fighter’s coat. But we in the fire service need to be continually conscious of the many characteristics of various types of rope.

The traditional rope of the fire service is made of the natural fiber, manila. Manila rope can be purchased in different grades. Yacht rope is the best quality grade, followed by boltrope. These ropes are light in color and up to 15 percent stronger than no. 1 manila rope. Most suppliers usually do not handle these top two grades.

The most commonly used grade for the fire service is no. 1 manila rope. It is strong, durable and resists weathering fairly well. However it can be somewhat costly when compared to synthetic fiber ropes. Since no. 2, no. 3 and hardware-grade manila rope deteriorate rapidly and have a short working life even when used on extension ladders, they should never be used in the fire service.

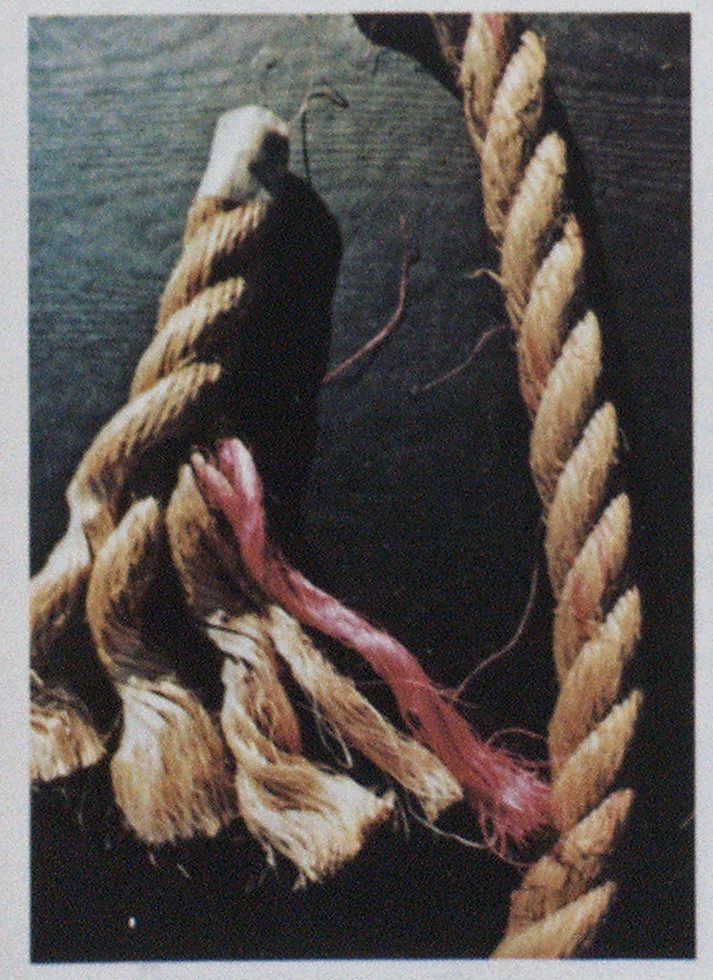

Colored strand

Most manufacturers mark no. 1 manila rope with a colored strand or a paper ribbon woven directly into the rope. A no. 1 manila rope without such markings should never be used for a lifeline. In any event, buy from a reputable dealer.

Manila rope also has some disadvantages. Over a period of time all manila ropes are subject to mildew and dry rot, even after being chemically treated. When washed and dried, it must be stored where air can circulate freely to prevent mildew and fungus from forming. When manila rope is washed and dried for the first time, it can lose up to 50 percent of its tensile strength—but only during the initial process. In addition, long exposure to sunlight will damage manila rope by drying out its natural fluids. When not in use, manila rope should always be covered or shaded.

Four synthetics

Synthetic fiber ropes have been in use for many years in mountaineering and shipping industries and are gaining acceptance in the fire service. There are four basic synthetic fiber ropes: nylon, polyester, polypropylene and polyethylene. They all have some advantages and disadvantages when compared with manila ropes.

Synthetic ropes come in several types of construction. The most familiar rope is probably the laid rope. Like manila rope, it is made by twisting the strands together. Three-stranded is the most common laid rope. Kernmantle ropes are made with a continuous filament core or kern. This core is then covered by a sheath or mantle. Hence the name kernmantle, meaning core covered.

Synthetic laid ropes are less costly and may provide a better gripping area than kernmantle ropes. However synthetic laid ropes may twist and stretch more, are less resistant to abrasion and are not as strong as kernmantle ropes. Kernmantle ropes also have less tendency to kink.

Generally, these synthetic ropes have greater strength than manila ropes of equal size. They also resist rot, mildew, fungus and moisture better than manila rope. The strength of synthetic rope is achieved by its individual fibers running perhaps the entire length, rather than the overlapping short fibers of natural ropes.

For equal size ropes, synthetics are lighter, easier to handle, and have more impact and fatigue-resistance than natural ropes. They also outwear manila ropes approximately four to one.

Nylon best known

Of synthetic ropes, nylon is the best known and has gained the most acceptance. It is about 2 ½ times as strong as manila rope, and resists abrasion and weathering well.

Nylon ropes are the strongest of the synthetics, followed by polyesters. One of nylon’s peculiarities is the fuzzing of its outer fibers, which slows the abrasion of fibers underneath. Nylon rope can also withstand severe shock load, the sudden energy applied when a fire fighter falling several stories uses a lifeline to catch his fall. This ability is ascribed to its high elasticity (10 to 14 percent stretch) under severe shock loading.

This stretching is almost nonexistent at normal working loads. However, elongation at its ultimate tensile strength (breaking point) can be as high as 40 percent.

With this degree of stretching, a new nylon rope needs to be broken in by loading the rope. This can be accomplished by rappelling or by using a telpher line to suspend a heavy weight. The new nylon rope will stretch approximately 7 percent. This is a permanent one-time-only increase. Any later stretching due to shock loading will be completely recovered thereafter.

Nylon ropes can be stored wet without fear of mildew or rot. Nylon is also highly resistant to alkalis but is rapidly attacked by most acids. With all ropes, synthetic or natural, contact with chemicals should be avoided.

Kernmantle rope

The kernmantle nylon ropes show the most promise for the fire service. With this type of nylon rope the load is divided between the outside sheath and core fibers. Any damage sustained to the outside sheath only affects 20 to 50 percent of the rope’s initial strength, while 50 to 75 percent of that strength remains in the core.

Polyester ropes are almost identical to nylon in appearance but differ in other physical characteristics. They are heavier, not as strong and can absorb only approximately two-thirds of the shock load of nylon ropes. They are superior to nylon ropes in some respects, such as resistance to acids, alkalis and stretching. But again, all chemical contact should be avoided and any rope subjected to chemicals should be thoroughly washed.

Polypropylene (water-ski rope) has a smooth slippery texture and is available in many colors. Polypropylene is not as tough or as strong as nylon or polyester but does have some other advantages. Polypropylene floats on water and is highly resistant to acids and alkalis. However, polypropylene ropes may fail when used around hot gases and radiated heat. Prolonged exposure to sunlight will cause deterioration of polypropylene.

Polyethylene has few advantages over manila rope. One, however, is its high resistance to alkalis and strong acids, with the exception of nitric acid. Polyethylene is also resistant to alcohols and bleaching solutions but is unsuitable for use around heat.

Safe working load

Safe working loads (S.W.L.) are determined by dividing the breaking or tensile strength of the rope by five. Thus rope rated at 3000 pounds breaking or tensile strength has a S.W.L. of 600 pounds.

Rope is rarely used without knots, hitches or bends, which reduce the ultimate strength of the rope. For example, a bowline causes a 50 percent reduction in safe working load. Hitches have much gentler turns and therefore only reduce the rope’s breaking or tensile strength by 25 percent.

Knots and hitches are not additive when determining S.W.L. This means the ultimate strength is only reduced by the greatest loss. Two bowlines at 50 percent loss each do not in reality equal 100 percent loss of strength. For a bowline (50 percent) and a clove hitch (25 percent) on a rope, use only the bowline’s 50 percent reduction in S.W.L.

Calculating S.W.L.

A rule of thumb can be used to calculate S.W.L. For manila, convert the rope’s diameter to eighths of an inch. Square the numerator and multiply by 20. A 3/4-inch manila becomes 6/8-inch. Six (the numerator) squared is 36. Multiply 36 by 20, for a S.W.L. of 720 pounds.

For nylons and polyesters, convert the diameter of rope to eighths of an inch. Square the numerator and multiply by 60. A ½ -inch nylon becomes 4/8-inch. Four squared is 16. Multiply 16 by 60, for a S.W.L. of 960 pounds.

These are only approximations. Remember, the condition of the rope will also limit the safe working load.

In summary, check with your suppliers for types and availability of ropes. Determine what performance, tensile strength and conditions you may be encountering. Contact several manufacturers of rope and request a fact sheet and specification information. Also inquire about Union International Association of Alpinistes (UIAA) testing or other methods. Otherwise, the rope you buy may literally have you hanging by a thread.

Comparisons of Synthetic and Manila Ropes