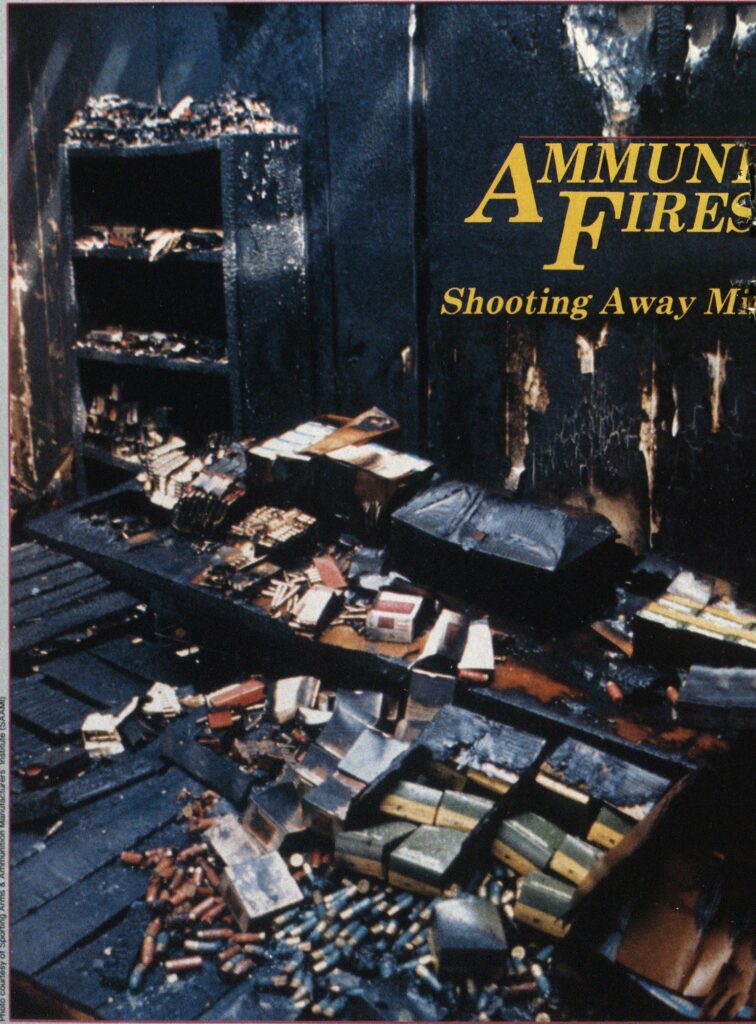

AMMUNITION FIRES

FEATURES

SPECIAL RISK FIRES

How does your fire department handle a fire involving small arms ammunition ? If your procedure is to stay back or run in the other direction, then this article will be of interest to you. It may mean reducing your property damage losses by several thousands of dollars.

With billions of sporting or small arms cartridges and shotshells transported by commercial carriers and stored in warehouses and retail outlets, the potential for encountering a fire involving ammunition is very real. There are more than 450 different types of sporting ammunition used by the recreational hunter and shooting enthusiast, necessitating an understanding of the expected behavior of these products during a fire.

Studies conducted by the Fridley, MN, Fire Department in July 1983 tested the characteristics of small arms ammunition when involved in a fire. The studies concluded that such fires can be safely and efficiently handled by firefighters wearing standard turnout gear with face shield. Three principal conclusions drawn from these studies are that:

- When ammunition is involved in a fire, it will not mass detonate or explode.

- Projectiles from the ammunition are low velocity and do not present any significant hazard to firefighters wearing standard turnout gear and face protection.

- The fires are readily extinguished by normal water application on the ordinary combustibles. Ammunition will not support its own combustion.

Over 281,000 rounds of ammunition containing more than 394 pounds of powder were used during the tests. The tests were conducted at the request of the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMl) in Wallingford, CT, which is composed of 11 American companies and two Canadian companies that manufacture small arms ammunition and firearms. SAAMl supplied all the ammunition used in the tests.

The Fridley Fire Department developed five test studies that supplemented five separate tests developed in 1974 by SAAMl in cooperation with the Chicago, IL, Fire Prevention Bureau. The 1974 tests consisted of the following;

- Drop impact test. To determine the effect of impact on sporting ammunition, cases of ammunition were dropped from a height of 30 feet onto concrete pavement. The impact caused the packaging cases to break open, but no cartridges fired.

- Bullet impact. Cases of centerfire rifle cartridges, shotshells, and .22 caliber rimfire cartridges were fired at with a .308 Winchester caliber rifle. In some instances, a few cartridges or shotshells within the packing cartons fired because of the high impact from the bullet fired at them, but in no instance was there any evidence of mass propagation or explosion of the cases containing the cartridges and shotshells.

- Firing of an unsupported cartridge. In two separate tests, a centerfire cartridge and a shotshell were each loaded into a device without the support of a cartridge receiver (barrel). The shells were each in turn fired into a fiberboard box typical of the cartons in which the shells themselves are stored and sold. None of the components of the cartridges, including the projectile, penetrated the fiberboard box and were contained therein.

- Confined burning. Cases of ammunition were placed in a speciallybuilt 6 X 6-foot concrete block structure, and oil-soaked scrap lumber was stacked beneath the ammunition. A V^inch thick flat boilerplate was placed on top of the structure to complete the confinement of the ammunition cases. The ammunition was allowed to burn for about 36 minutes. The heat of the fire was so intense that it collapsed a grill that was holding the ammunition above the oil-soaked lumber. In addition, cracks developed in the concrete block mortar joints. Mass detonation of the ammunition did not occur.

- Ammunition in a burning structure. Thousands of rounds of ammunition were placed in a wooden frame building and the building was ignited. The building was allowed to burn to the ground. Mass detonation did not occur, and projectiles from the burning ammunition did not achieve a velocity that would cause danger to a fully protected firefighter.

The second set of five tests conducted last year by the Fridley Fire Department were developed specifically to demonstrate how firefighters may easily and safely extinguish a fire involving sporting ammunition. The demonstrations were based in part on recommendations received from the Hazardous Materials Committee of the International Association of Fire Chiefs.

- Structural fire —direct attack. Over 53,000 rounds of ammunition were placed in a retail store scheduled for demolition. The heat from the Class A (ordinary combustibles) fire resulted in a char depth of ½ inch in the 2 X 12-inch roof joists. Fire initiation and propagation was achieved by using a large quantity of cardboard and dry pine kindling wood that had been soaked with fuel oil. A direct interior fire attack was made using a l’/j-inch line with a 95-gpm fog nozzle initially set at a 45° pattern. The firefighters wore full protective gear including self-contained breathing apparatus (SCBA). The fire was extinguished uneventfully in 34 seconds.

- Fire in a closed trailer. Since most sporting ammunition is shipped in the United States by truck-trailer, three trailer fire tests were developed. The first trailer fire test involved over 94,500 rounds of ammunition. The ammunition was loaded adjacent to an abundant supply of ordinary combustibles in the nose of a trailer. This demonstration simulates the condition firefighters normally encounter, that is, a fully involved trailer in which the contents are unknown. The fire inside the trailer was allowed to progress from a stage 1 (incipient) to a stage 3 (smoldering) condition. The trailer was “breathing” (prelude to backdraft), attesting to the presence of super-heated gases and an insufficient oxygen supply The trailer was ventilated at the top and a small quantity of water was applied through a fog nozzle at a rate of 95 gpm. After application of approximately five gallons of water, the breathing condition was arrested. The rear door of the trailer was then opened and a direct attack was made on the fire. The fire was easily and, again, uneventfully extinguished.

- Trailer fire — indirect attack. Since many fire departments do not have full turnout gear for their members, a special demonstration was conducted to illustrate how firefighters may approach a trailer fire involving sporting ammunition and obtain some margin of protection by the walls of the trailer. In this demonstration, a Class A fire including ammunition was allowed to free burn, and it eventually burned holes through the sides of the trailer. The firefighters approached the burning trailer from the rear at approximately a 45° angle. They moved toward the nose of the trailer and located the burned holes on the sidewalls from which flames were visible. A straight-stream application of water was directed through the holes and against the ceiling of the trailer to break up the stream. The indirect water application destroyed the vertical heat column from the fire. By observing the change in the volume and color of the smoke, the firefighters could determine when the free-burning fire had been reduced to a smoldering fire. Firefighters then commenced a direct attack on the fire through the rear door of the trailer. Again, the fire was easily and uneventfully extinguished.

- Trailer fire —direct attack. The last trailer burn demonstration illustrated the direct attack extinguishment method. A free-burning fire, including small arms ammunition, was developed in the nose of the trailer. The firefighters approached the trailer from the rear with the rear trailer door removed. Protected by full turnout gear including face protection, the firefighters used a lV2-inch hose line with a 95-gpm nozzle. A backup line of the same size and with the same type nozzle was also used. The firefighters moved directly toward the fire. By using alternate wide pattern fog and straight streams, they extinguished the fire in two minutes. The use of a wide pattern fog nozzle served two purposes:

- It moved the smoke away from the firefighters, thereby enhancing the visibility of the ordinary combustibles that were burning.

- The water from the fog nozzle stopped any small projectiles from striking the firefighters. While those projectiles do not have sufficient mass and velocity to penetrate the firefighters’ turnout gear, it is an annoyance and can be unsettling to firefighters when they’re struck by the particles.

(continuedon page 19)

(continued from page 16)

Characteristics of a small arms ammunition fire

The most unsettling part of attacking a fire involving small arms ammunition is the amplified popping sound that ammunition makes when it burns. As the fire’s intensity increases and the amount of the ammunition involved increases, the popping increases. When confronted by that sound, a firefighter can reasonably be expected to retreat, unless he understands the behavior of the ammunition when exposed to heat. The popping sound quickly abates when the ordinary combustibles around the ammunition are cooled below their ignition temperature.

The second noticeable and unsettling condition is that the firefighter in close proximity to the sporting ammunition may be struck by small metallic fragments. If the firefighter does not wear full protective gear, the fragments can cause superficial flesh wounds or eye injury. Therefore, full protective gear must be worn. Additionally, the use of a wide pattern fog nozzle stops most, if not all, of these low velocity projectiles.

Overhaul of the fire

During the demonstrations, we noted the importance of totally saturating the ordinary combustibles containing sporting ammunition. This was important because firefighters tend to remove protective equipment during the overhaul process. Before the ordinary combustibles are totally saturated, there may be hot spots remaining, and if ammunition is in those hot spots, the heat from the ordinary combustibles can cause the ammunition to burst. Therefore, firefighters must keep their full protective gear on during overhaul to avoid any injury from metallic fragments emanating from the burst cartridge or shotshell. The need for facial protection in particular cannot be stressed enough.

Firefighting strategy

During the fire department’s test demonstrations, it was noted that there is a significant increase in the volume of smoke emanating from a fire involving small arms ammunition than would typically be found in a free burning fire. The reasons for this are that plastic is now used for the shotshell’s casing; uncontrolled propellants burn greater in open areas than in confined spaces; and the burning powder or propellant contained in the shotshells and cartridges gives off more smoke. Therefore, it’s recommended that normal ventilation be increased to allow for desired dissipation of the smoke from the fire.

When confronted with any fire, firefighters must be aware of the contents involved. While sporting ammunition itself does not present a significant hazard, other commodities should be considered. For example, products normally shelved in retail outlets or warehouses alongside small arms ammunition include aerosols, propane cylinders, camp stove fuel, etc. These products present far more significant hazards than the small arms ammunition (see FIRE ENGINEERING, Volunteers Corner, February 1984).

Conclusion

The tests conducted by SAAMI in conjunction with the Chicago Fire Prevention Bureau and the special demonstrations conducted by the Fridley Fire Department show that:

- Fires involving sporting ammunition can be safely extinguished by using attack lines equipped with fog nozzles set at a 45° to 60° pattern, and by firefighters having full protective gear and face shields.

- Any metallic projectiles emanating from ammunition burned is low velocity. The highest velocity projectile from the burning ammunition will be the primer cups. Because the primer cups are lightweight and have poor aerodynamic shapes, their trajectory can be stopped easily with the wide pattern fog nozzle.

- The bullet component of a cartridge will not achieve high velocity when propelled from burning ammunition; its velocity and penetration capability is not comparable to a bullet being fired from a firearm.

- The strategy for an attack on ammunition fires is to cool the ordinary combustibles around the ammunition to below ignition temperature.

- The ammunition does not support its own combustion.

- Additional venting tactics should be used at fires involving structures storing small arms ammunition.

A video training program based on ihe.se fire tests are available to all fire service organizations. Entitled Sporting Ammunition and the Firefighter, requests for information about these training materials, as well as any questions concerning the fire tests can be directed to Chief Robert D. Aldrich, Fridley Fire Department, 6431 University Avenue N.E., Fridley, MN 55432.