Wooden Structures High in the Sky

FEATURES

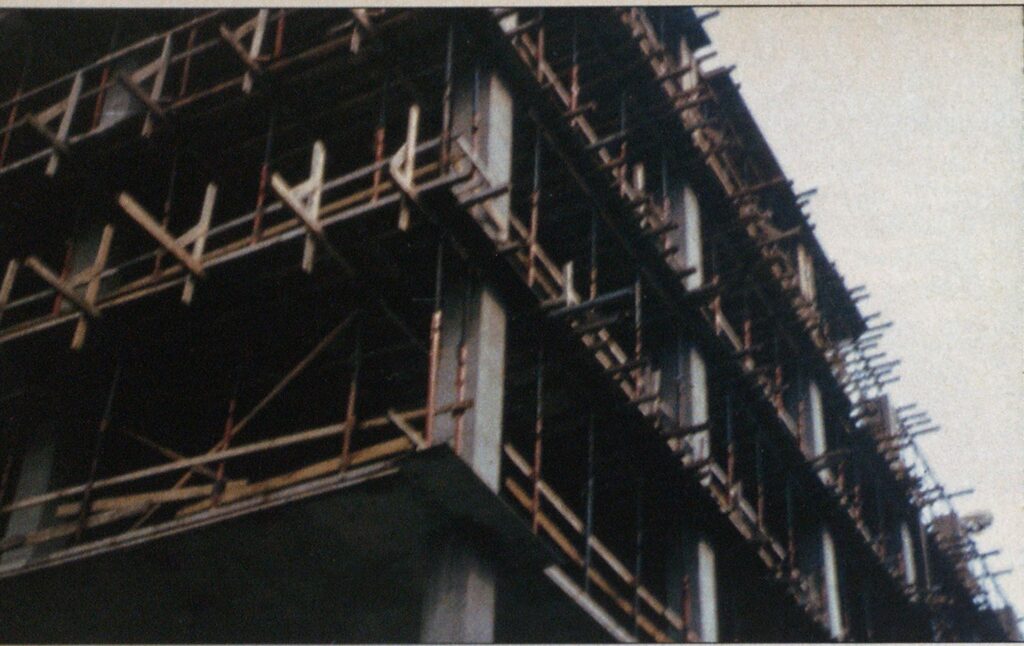

BUILDING CONSTRUCTION

In high-rise 1973, 24 under floors construction of a concrete in northern Virginia collapsed, killing 14 workmen. A picture of the collapse was used in a flyer for one of my slide sets. I received a call from the dean of architecture of a prominent university. He asked me: “What has this collapse to do with the fire service? How is it a concern of yours?”

I told him there were four principal points of interaction:

- The fire service is often the first organization involved if anything goes wrong.

- The fire service is the only onganization equipped to do the necessary rescue work, and is very often the emergency medical ser-

- vice (EMS) provider at the scene.

- The results of this incident would have been identical if the falsework had been removed by

- fire, rather than by laborers wielding sledges.

- There is always the possibility that some construction supervisor like him, running around with a white hard hat and giving us advice, is already guilty of a felony and would like to sucker us into helping cover it up.

With that last point the conversation turned frosty, and the earlier, cordial invitation he had extended me, to lecture to his students, was never followed up.

This disaster involved construction workers; the fire service performed rescue operations. However, in the construction of concrete buildings, there is a potential for a massive firefighter tragedy.

Potential parallel

We recently have seen pictures of the horrible problems faced by rescuers in the Mexico City collapse. I am sure many of you offered a silent prayer of thanks that it was not your problem. It certainly can be your problem, though and your firefighters may be the entombed victims.

In this article we will address the extreme life hazard to firefighters who use “generally accepted, conventional, aggressive fire suppression tactics” at a fire during the construction of a cast-in-place reinforced concrete building.

(Photos by Frank Brannigan)

Reinforced concrete

Plain concrete is a cementitious mixture of water and portland cement to which an inert aggregate such as sand, stone, vermiculite, or some other material is added. The Romans used plain concrete extensively as a substitute for stone, but only in compression because it lacked tensile strength.

About 100 years ago, steel was added to the concrete to provide tensile strength, and reinforced concrete was born. Reinforced concrete is a composite material. If the bond between the concrete and steel fails, there is no longer a structural element, just useless weight.

Cast-in-place concrete is made where it will remain. It is placed as a pliable plastic and takes the shape of the form that is constructed. The formwork is supported by falsework. This formworkfalsework combination can be as much as 60% of the cost of the concrete structure, so there is every incentive to economize. It is often built by persons quite unfamiliar with all the potential hazards involved. There is little or no reserve strength.

In 1975, the concrete roof of a Cupertino, CA, shopping mall collapsed while it was still under construction. A trade publication article noted, without any surprise, that the failure of a single 4 x 4 in the falsework precipitated the collapse. Designers, constructors, and, tragically, many fire officers have little or no understanding of the catastrophe that a fire could cause. A few really knowledgeable people are astonished that firefighters would situate themselves anyplace below burning falsework, which is supporting the weight of a concrete floor.

Fire department policy

How many fire chiefs could make the following statement? “At all times our fire suppression forces are completely informed up to the minute as to any concrete that is supported by fire—vulnerable falsework—and our operating procedures are clear and explicit: ‘No personnel are to be in any location where they are endangered by the potential collapse of the structure during a fire in a concrete building under construction.’ This policy has been made clear to all involved in the construction of concrete buildings.”

Few, if any, chiefs have enunciated the above policy. If your department has such procedures, don’t sit there being smug. Please make that information public. Such procedures will be widely adopted as policy after a terrible disaster occurs, but never universally. There are always those who do not get the word, or, as one chief said after a multiple firefighter fatality in the Midwest, “I learned nothing. I would use the same tactics again.”

This problem cannot wait for a solution until the command structure is set up or the building department is called; the disaster may involve the first-arriving units which are making a conventional attack.

Conventional vs. posttensioned concrete floors

There are two types of concrete floor reinforcement: conventional reinforced and post-tensioned. In the conventional reinforced, steel rods are laid out in the form, according to design. The concrete is poured under, around, and over the rods. As the concrete sets and cures, it bonds to the steel, and the reinforced concrete composite develops, having both tensile and compressive strength. After a while, it is safe to remove the falsework, and the floor is capable of delivering its loads to the columns (or wall).

In post-tensioning, cold drawn steel tendons, which may be cables or rods, are laid out in plastic sheaths. Then the concrete is poured. There is no bond between the tendons and the concrete. Samples of concrete, as poured, are sent to a laboratory. When the concrete sample has cured sufficiently to stand the compression, a hydraulic jack is used to tension the tendons, thus placing the concrete in compression. The tendon is locked so that it stays in the tension.

This process is known in the trade as “jacking the cables.” When the jacking is completed on a floor segment, the load is transferred to the columns.

However, we are not home free, as we will see later. Until this process is completed, the entire weight of the concrete is resting on the falsework with no other support. The floor will be hard and dry, people will be walking on it, material will be stored on it, and the falsework and formwork for additional floor(s) will be erected on it.

If the falsework is damaged by fire, the floor being supported must collapse. Gravity is inevitable. Concrete structures are not resistive to progressive collapse. If one floor falls on another, the collapse stops in the basement.

I presented this hazard in a paper at the National Fire Protection Association (NFPA) meeting in 1971. The talk was reported in ENGINEERING NEWS RECORD, a construction trade publication, so it certainly came to the attention of the concrete construction industry. No one in the construction field said I was wrong, but the editor of a journal for the fire protection industry said, “I just can’t believe that they are building buildings that can collapse completely.” And the editor refused to print the paper.

(Photo by Frank Brannigan)

Apparently, many fire officers have the same opinion. Fortunately, retired Chief Barry of the Cleveland, OH, Fire Department did believe it. A fire in the falsework of a 16-story post-tensioned building caused it to collapse totally. However, you never heard about it, because the firefighters were not under the collapse. Chief Barry told me that between responses he returned to his office and re-read the chapter on concrete construction in my book, BUILDING CONSTRUCTION FOR THE FIRE SERVICE.

The owner reportedly blamed the collapse on “water thrown by the fire department.”

An ordinary wooden building with a six-inch concrete roof would be a structure of real concern and would be marked for immediate defensive firefighting. This is exactly the situation with post-tensioned concrete. One building was described as having five concrete floors awaiting tensioning at any one time. In effect, these are five concrete roofs on wooden studs.

Bailey’s Crossroads collapse

When I first looked into this problem, I was assured that the situation was different in the case of conventional concrete. I was told that when it is hard and dry, conventional concrete would be self-supporting. Perhaps that is so, but certainly not universally. This is graphically shown by that 1973 northern Virginia collapse, also known as The Bailey’s Crossroads Collapse. Laborers knocked out the falsework on the 23rd floor, which was supporting the 24th (top) floor, which was supposedly self-supporting. The 24th floor fell. Concrete floors cannot stand the impact of the collapse of the floor above. The entire section of the building totally collapsed.

(Photos by Frank Brannigan)

I have often said, “Panic will save your life, provided you are the first one to panic and are headed in the right direction.” In this case, those who calmly added shoring to the trembling building died. Those who “panicked” and ran down the stairs survived to testify to the grand jury. One survivor told how he jumped down from stair landing to stair landing, with men passing him!! Again, there is absolutely no difference between the laborer knocking out shores and fire burning them.

This collapse demonstrated that there is no essential difference between the failure of falsework in a conventional reinforced or post-tensioned concrete building. If the falsework is carrying the weight of concrete, wet or dry, total collapse will almost assuredly be the result. Therefore, it is essential that at all times, right up to the minute, the fire department be aware of the status of the loading.

The vulnerability of tendons

There is a special fire problem with posttensioned concrete. The tendons are cold drawn steel, which loses its tensile strength at about 800° F (less than the temperature of your self-cleaning oven and well below the failure temperature of structural steel). For a variety of reasons, the tendon ends are often left exposed after they are tensioned: ing is built and load is added to the beams.

- If the floor is large or the tendons change direction, a portion of each tendon is tensioned, and the balance is rolled up like a big hoop and hung on a wooden rail.

- After the tendons are tensioned, the ends are left hanging down until the general contractor cuts them off with a torch and “dry-packs” the hole. Any of this exposed metal could conduct heat to the part of the tendon past the

- anchor. If any part of the tendon is heated to 800° F, “you have burst the rubber band/’ in the precise technical terms used by a prominent fire researcher.

- • Large post-tensioned beams present a unique problem. The tendons are not cables, but bundles of rods. These are pulled by the jack, and a steel spacer is inserted between the anchor holding the ends of the rods and the face of the concrete. They are tensioned in increments as the build-

The ends of the tendons are left exposed directly to fire between tensionings. The protective “fireproofing” is not applied until the beam is fully tensioned. It is difficult to believe that an inconsequential rubbish fire in the pit holding the tendon ends could cause a total collapse, but it’s true.

Some years ago, I described this hazard to my friend Max McRae of the Houston, TX, Fire Department. They went looking. They found a situation where the tendon ends of huge beams were exposed to a possible fire in falsework for the next section. Their pre-fire plan had provided for them to drive under the tensioned section to get to a fire in the falsework. They changed the plan.

Non-combustible falsework

Not all falsework and formwork is wood. Sometimes the falsework is constructed of steel scaffolding. This is all to the good, unless the steel is exposed to fire in fuel, such as the literally tons of propane that may be in the structure for comfort heating or to keep concrete from freezing. The more heavily loaded steel is, the lower the failure temperature. Temporary steel structures are usually permitted loadings far greater than those permitted permanent structures.

Aluminum falsework and fiberglass forms look like a winning combination, until we realize that the fiberglass is “glass-fiber-reinforced polyester resin plastic.” The plastic is combustible, and a pile of forms certainly could provide enough heat to cause aluminum falsework to fail, particularly considering the heavy load.

The toughest thing to convince an experienced (and lucky) fire officer of is that certain situations demand defensive operations immediately on arrival, and this is one of them. It is imperative that the chief get his head out of the budget or other administrative measures long enough to determine exactly what his suppression forces would do if they responded to a falsework fire in a concrete building tonight. He should ask and answer a single question: Could our department suffer a terrible disaster by following our usual, aggressive tactics?

If the answer is “yes,” then he should ask: Are we going to change, or wait until we or some other department suffers a monumental tragedy?

If you don’t believe me, ask the building’s architect and structural engineer to answer this in writing: “What do you predict if a fire involves falsework that is supporting a concrete floor?” If you get a reply, put it in the safety deposit box.