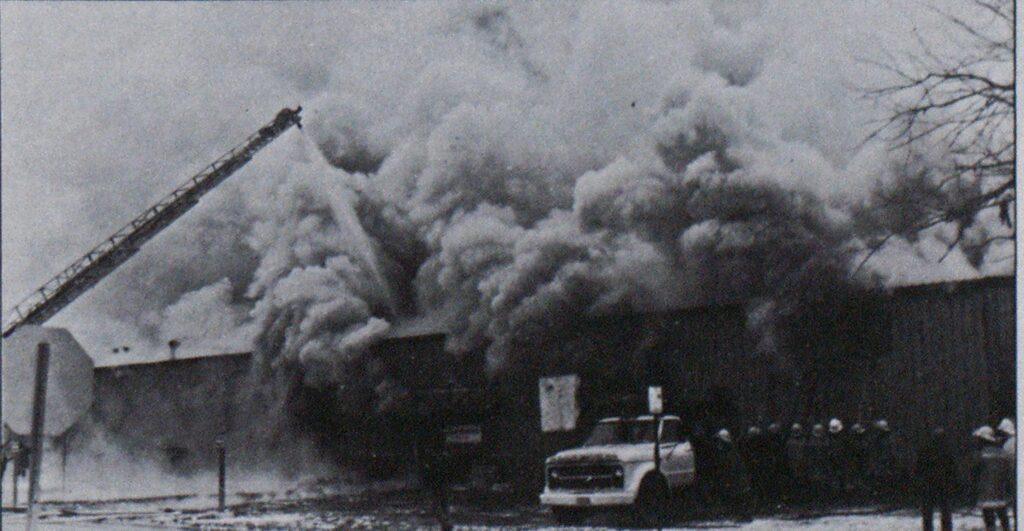

VOLUNTEERS BATTLE FIRE IN TOWN’S LARGEST INDUSTRIAL COMPLEX

FIRE REPORTS

“If you hit those three vacuum machines inside with water, they’ll blow up the whole block! We’ve also got 16 different chemicals stored in there!”

After hearing that warning from an employee of the Dassel, Minn.’s largest industrial complex, Fire Chief Orland Nelson ordered his men out of the 29,000square-foot steel industrial building and to pull back as a safety precaution. This was the beginning of an all-day, mutual-aid fire that was one of the biggest in the history of the rural community of 1000 located about 60 miles west of Minneapolis.

The modern one-story structure, occupied by two electronics firms and a law office; was destroyed with the loss estimated at $3.2 million.

“It was an economic tragedy for our area, but we were very fortunate that there were no serious injuries,” said Nelson, a dairy farmer and chief of the 30-man Dassel Volunteer Fire Department.

The first alarm was telephoned in at 5 a.m. by an employee reporting to work at Nortronics. The company, a maker of heads for tape recorders, calculators and computers, occupied the west end of the 200 X 140-foot building. The east end was occupied by the law firm and Crest Electronics, a maker of hospital signaling equipment.

All the Dassel volunteer fire fighters responded to the first alarm, given by a long ring at the home of each fire fighter and by sounding the fire siren atop the fire hall. The department, which protects a 130square-mile region and has 1600 rural fire service contracts, has three pumpers, one 2000-gallon tanker, a grass fire fighting vehicle and an all-purpose van.

The 1976 FMC high-pressure attack pumper was first out, according to response procedure, and crossed the adjacent railroad tracks to the fire about two blocks away. But the other trucks were delayed two or three minutes by a passing freight train.

Nelson was in the second pumper and upon arrival the captain of the first rig reported that paint was peeling at the 8-foot level on the west end of the steel-sided building.

“It was a tightly constructed building and we didn’t see any flames or fire,” Nelson explained. “But we knew it was hot inside and laid hydrant lines from our three pumpers.”

First entry was attempted through a door on the south side, but the fire fighters were driven back by heat and smoke.

“I knew then that we had a real fire,” Nelson said. He called at 5:10 a.m. for mutual aid from the neighboring Cokato Volunteer Fire Department, which responded with 12 men, one pumper, one all-purpose van and Fire Chief Reed Carlson.

The Cokato crew laid two 2 1/2-inch lines into the structure from a door midway along the north side, while Dassel tried again to enter from the south. The attack by the two departments was aimed at containing the fire to the west end of the building.

Flames were first seen at this time. Fire was beginning to roll out through the north and south doors, Nelson said. “We couldn’t get in.”

This is when the warning came not to hit the vacuum machines (production equipment located on the northwest side) with water and that a variety of chemicals were inside.

—Courtesy Dassel Dispatch

“No one was trapped in the building and it wasn’t worth risking lives over, so I ordered a general pullback,” Nelson explained, adding that the Dassel attack pumper was shut down temporarily.

“We knew there were some chemicals inside because of an earlier inspection, but I wasn’t aware of an explosion danger from the firm’s production equipment, the c hief said. As it turned out, the three vacuum machines imploded in the fire without harming anyone.

However, the 16 chemic als, in various volumes, were later identified as alcohol, acetone, Atomite, adhesives, Chlorothene, ferric chloride, Freon, paint, varnish and several types of epoxy. These chemicals constituted the major danger and posed a potential threat to the community of Dassel. The chemicals were stored at the west end of the structure, where the fire apparently started, and the containers began to explode, creating heavy, black smoke. Because of the danger, Nelson decided to let the chemical storage area burn.

The wind was from the northwest, blowing the dark clouds of toxic smoke away from town. Nelson checked with the United States Weather Bureau and was relieved to hear that no wind change was anticipated. Dassel would not have to be evacuated.

Fire fighters without SCBA were kept upwind or a safe distance from the smoke. When the limited supply of SCBA air bottles ran low, the Dassel police took empty air tanks 9 miles to Litchfield and 14 miles to Hutchinson for refilling, while the Minnesota State Patrol shuttled empty cannisters to Buffalo, 25 miles away, to be replenished by the Wright County cascade system.

At 6 am, a mutual-aid call was made to the Hutchinson Volunteer Fire Department for its 100-foot aerial so that the fire could be attacked from above if the metal roof fell in. However, the roof was held up by heavy steel I-beam roof supports over a line of iron posts through the center of the building.

A six-man crew, including Chief Lloyd Sletter, came with the Hutchinson aerial, and at 6:30 a m. the Wright County cascade system was dispatched to Dassel for faster filling of air bottles. The Montrose Fire Department, 15 miles away, also responded with its truck-mounted cascade system and refilled air bottles for all four departments.

Fed by exploding chemicals the fire continued to spread through the production area toward the east end of the structure. At 7:50 a m., the Litchfield Fire Department was called to help protect the east end.

Litchfield responded with 12 men, a 1250-gpm pumper, utility van and Assistant Chief Gene Thomas. Litchfield laid two 2 1/2-inch lines and wyed both to better protect the east end of the building. Most of the Crest Electronics office records were saved.

By 8 am, approximately 60 volunteer fire fighters were at the scene. Dassel Captain Bruce Lindquist was in charge of the west and south sides, while Assistant Chief Ron Rauschendorfer worked with Litchfield and Cokato officers on the east and north sides. Lindquist and Rauschendorfer communicated with Chief Nelson via hand-held radios.

Access to the interior of the steel paneled building was a problem. An all-purpose power saw was used to cut holes in the sides so exterior hoses could hit the intense fire in the center of the structure. The city front-end loader also was used to break open hot spots along the walls.

As the fire department pumpers increased their hydrant pumping, the Dassel municipal water supply, fed by a 55,000gallon elevated tank, began to draw down. Tankers from Dassel, Cokato, Litchfield and Hutchinson then supplied portable holding tanks that were set up on the fireground. The portable tanks were used whenever it was necessary to give the city pumps time to build up the level of the municipal water tank.

Because City Maintenance Chief Dave Crochow, a volunteer fire fighter, was at the fire, his assistant, john Holmgren, watched the municipal water tank level and gave Nelson reports about every 15 minutes. Nelson then decided when to switch to the portable tanks.

An attempt was made to avoid applying water on the chemical storage area to avert potentially explosive reactions and to minimize water runoff problems. Otherwise, the exterior attack with heavy hose lines continued into the afternoon.

The fire was under control by 2 p.m., but the mutual-aid companies were not released until late afternoon because of several hot spots. The Dassel Fire Department remained at the scene until 4:30 p.m. the next day — nearly 36 hours.

LESSONS LEARNED

More than 350,000 gallons of water were pumped on the fire and some 200 air bottles were used by the 60 fire fighters. Only one fire fighter, whose air pack malfunctioned, was taken to a hospital where he was treated and released. Fatigue, however, was a common problem.

The cause of the fire which occurred last November 5, has not been determined.

Assessing the response in terms of a small volunteer fire department, Nelson made the following comments:

- “Fortunately, our department invested in new air packs a couple of months before the fire. They were of critical importance for us, and our experience proves the need for first-class SCBA equipment, plus a system for refilling empty air tanks.

- “A small-town chief faced with a major fire is not likely to have all the experience necessary to confidently make difficult decisions. Therefore, it is desirable for neighboring chiefs to respond on significant mutual-aid calls because they may be needed for consultation. My fellow chiefs gave me excellent support.

- “Small volunteer fire departments, like larger departments, should have portable radios for their chief officers. Our two-way radios enable me to keep in constant touch with all fire sectors, trucks and the fire hall. I was on the radio much of the time.

- “It takes a lot of good officers and men to handle a situation like this, and we had them. They all did an outstanding job. But we learned that a small department needs to have a planned system for relief and rotation of its limited manpower when a fire emergency extends for many hours.

- “We had a favorable wind, but our experience showed the need to have a workable plan for evacuating large segments of the community at night or in the early morning hours.

- “The municipal water supply held up pretty well for a community of our size, but other small departments might consider how they would handle a sudden fire demand for 350,000 gallons of water.”

Nelson and his fellow chiefs believe their regional mutual-aid network responded well; and they are confident that the use of a cautious approach avoided serious injuries from a dangerous industrial fire.