Vertical Stokes Lower via a Roof System

FEATURES

RESCUE TECHNIQUES

Consider this situation: A multiple alarm fire in a six-story structure has rendered the interior staircase and fire escape unusable. A severely injured fire victim, who had been taken to the roof, must now be evacuated. Due to the still ongoing firefight and the limited number of fire personnel, only three firefighters are available to execute a removal of the victim via Stokes basket and rope.

Consider another incident: A mountain climber suffering from a bad fall must be lowered off the side of a cliff in a Stokes basket. The narrow area and rugged terrain allows for a minimum number of rescue personnel at the scene.

Only after all other avenues of escape have been eliminated should we attempt a rope rescue, as removing victims from above (or below) grade level requires special consideration and training to avoid causing additional injury. However, not having a full squad of rescue personnel should not be a consideration in this type of rescue.

ROOF SYSTEM PRINCIPLE

With today’s new technology and techniques, a vertical Stokes lower can be performed with as few as three emergency personnel—and from a roof, a cliff, or an upper story window.

Called the roof system, this lowering procedure works on the basis of anchoring (tying off your roof system to a substantial object). There are three basic types of anchoring: multiple, equalizing, and non-equalizing.

NOTE: The individual using these anchoring methods may not use the traditional mountain climber’s approach due to the urgency of the fireground or rescue situation.

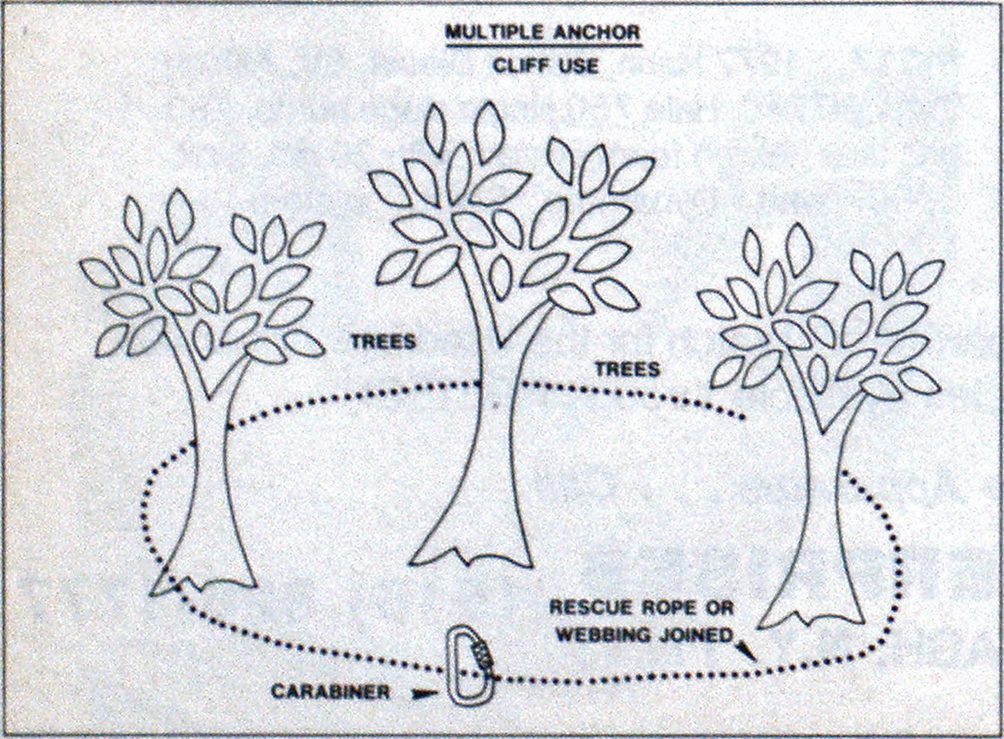

The multiple anchor consists of running a piece of rescue rope or webbing around two or more substantial objects. This divides the full weight of the descending pull between or among the anchors. For example, if the Stokes weighs 300 pounds, including victim and equipment, a 300-pound pull on a single substantial object might stress it enough to pull loose. However, if you run the rescue rope around, say, an air conditioning unit, a chimney, and heavy pipes, that 300-pound pull is now divided by the three objects, netting a 100-pound pull per object.

The equalizing anchor requires two substantial objects for tie off. This forms a “moveable” anchor, which is extremely helpful when your substantial object is off to one side of the roof, cliff, or window ledge section where your rope has to go over. With this method, a safety loop is inserted just before the carabiner so that if one of the anchors pulls away, the slack will be taken up and the carabiner will not pull off, thus maintaining the system’s integrity.

The non-equalizing anchor is useful when tie offs are uneven (meaning one anchor is high and the other low) or when you have to work around overhangs or sidewalls. With the non-equalizing anchor, a separate length of webbing or rescue rope is tied to each substantial object and affixed with a like number of carabiners. The anchor ropes are then crisscrossed to form an artificial substantial object away from the natural substantial objects, and the carabiners are attached to a Figure 8 fitting with ears.

SETTING UP THE ROOF SYSTEM

Once you’ve anchored your system, stabilized the victim, and secured him in the Stokes with a one-point suspension,1 you’re ready to attach the lowering device and descending line.

The lowering device is the locking carabiner connected to the anchor rope(s) and the Figure 8 fitting with ears. The rescue rope is hooked up through the Figure 8 ring and then the ring is clipped to the anchor point [carabiner(s)]. The rope bag is placed by the anchor point to feed the system. The running end of the rope (that end of the rope that is used to form the knot) is pulled through the ring and brought to the top of the Stokes basket. A Figure 8 knot on a bight is then tied in this running end and a locking carabiner is connected to it. A sling is then attached to the Stokes basket.

Photos by David M. Cordts

This sling is formed by tying a 15-foot piece of webbing together with a water knot and run around the two top vertical Stokes supports, giving the operation more flexibility by enabling the Stokes to move in the direction of the tag lines (guidelines). However, if you’re not comfortable using the webbing, a piece of 1/2-inch to ⅝-inch rope can be substituted, tying a double fisherman knot.

ACTIVATING THE ROOF SYSTEM

Two firefighters bring the Stokes basket to the edge of the roof, window, or cliff, and the third firefighter belays (holds the rope) at the anchor.

Roof system equipment

Two rescue ropes. These should be of synthetic fiber, between 9/16 and 5/8 inch in diameter, and have a minimum breaking strength of 10,000 pounds (see “Selecting Rope for Fire and Rescue Operations,” FIRE ENGINEERING, April 1983). One rope should be long enough for a descent, and the other rope should be kept around you for possible anchoring purposes or a backup line.

Two tag lines. These should be as long as the descent line, but may be smaller in diameter.

Four webb slings. For rescue purposes, the webbing is a tubular, one-inch wide, spiral, nylon material having a tensile strength of 4,000 pounds.

NOTE: If a length of more than 15 feet is needed, rescue rope should be used instead of webbing, since most lengths of webbing carried are no longer than 15 feet.

One large Figure 8 ring with ears.

The Figure 8 is the mainstay of the lowering operation, and the ears will prevent a rope lockup in the event the rope slides over the ring. Depending on the manufacturer and on particular Figure 8 rings, it is possible to have a tensile strength in excess of 10,000 pounds.

Four carabiners. You should use a locking carabiner having a minimum tensile strength of 5,500 pounds. Although steel is generally thought of as the strongest material, there are certain designs in aluminum that are stronger than steel designs.

The belaying firefighter has all the weight of the Stokes basket and victim and total lowering control as he feeds the rope through the Figure 8 ring. The Stokes is guided around obstacles by the two ground controlled guidelines.

Since the belay position is most often away from the edge of the building or cliff and out of sight of the Stokes basket being lowered, communications is extremely important. A firefighter positioned forward of the belayer so as to observe the Stokes’ descent and help guide the belay operation is invaluable in such a situation.

SUMMARY

Once again, consider all other avenues of escape before attempting a rope rescue, and be sure that those executing the rescue have been properly and thoroughly trained.

Examine your rescue capabilities (manpower, equipment) as well as weather and terrain conditions before performing any operation, and make full use of communications and coordination between the roof team and ground personnel.

A one-point suspension means that the center of gravity remains in one position throughout the movement.