Scenario: “Man is unconscious, possibly overcome with fumes, in forward emergency fire pump room. Enter hatch deck B forward starboard.”

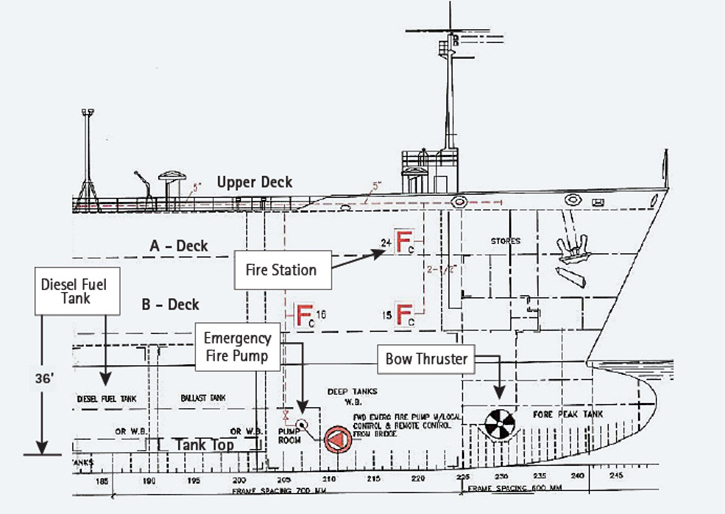

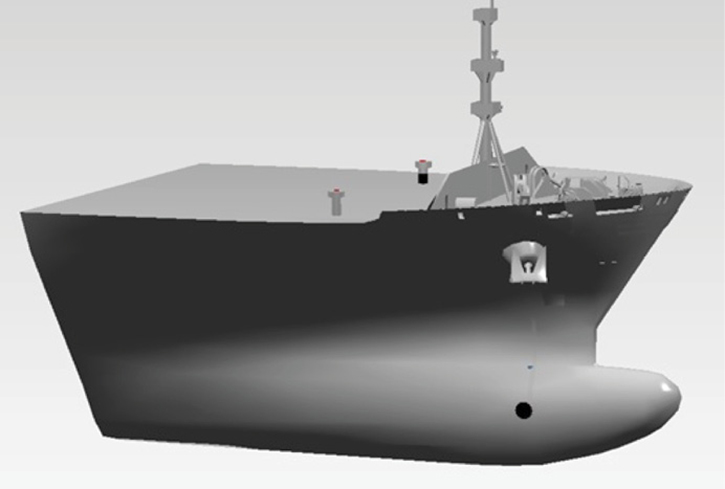

That was the training drill scenario on a ship like the one in Figure 1. The rescue team used the ship for a training exercise but did not intend to address issues unique to ships. Nevertheless, the drill served as a learning experience.

Ship Nomenclature

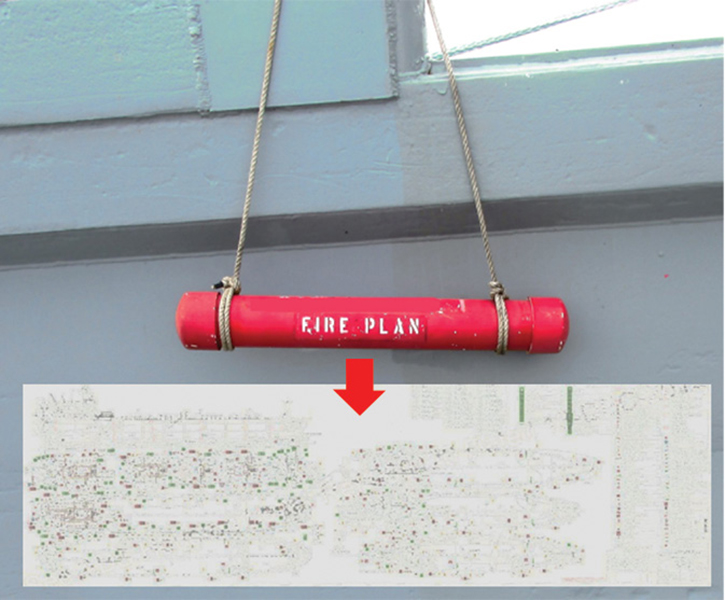

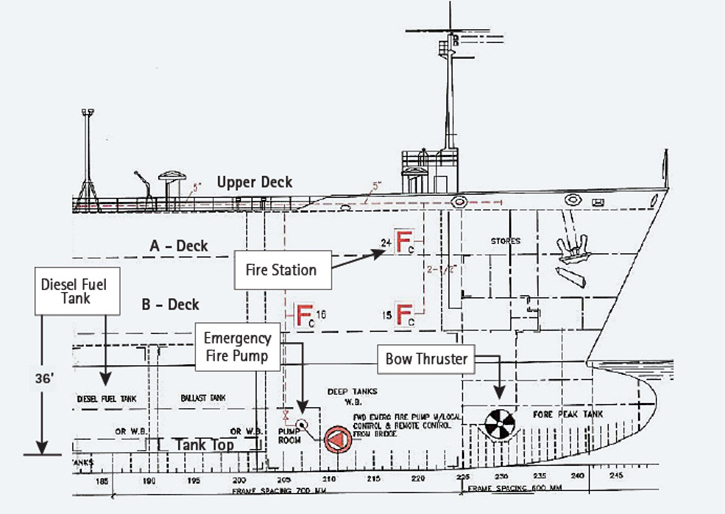

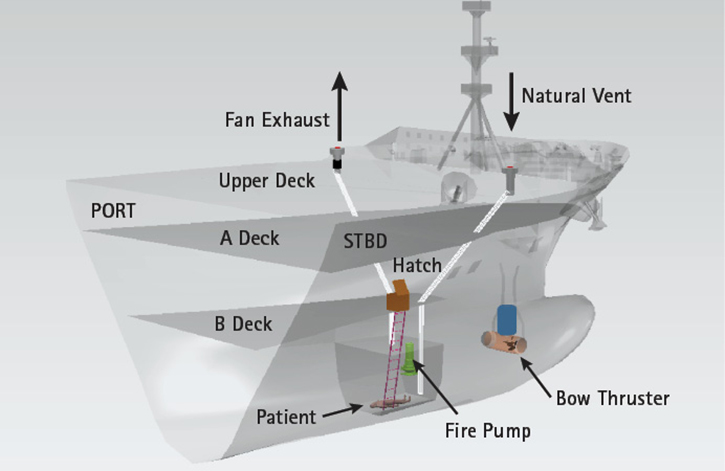

The first consideration for this rescue is the ship’s layout. On most ships, the uppermost deck that covers the length of the ship is called the “upper deck” or the “main deck.” Decks above that are in the house of the ship, which includes accommodations, offices, and the bridge; they are sometimes labeled 01, 02, 03 or A, B, C and so on. Below the main deck, decks are sometimes labeled 1, 2, 3 or A, B, C and so on. The lowest level is often called the “tank top” because the level is above the double-bottom spaces or tanks. The crew can inform you on how a particular ship is labeled. Alternatively, most ships have a fire plan stored at the entrance to the ship in a tube (photo 1). The fire plan may be a three- × eight-foot drawing of the ship’s profile and deck layout, a list of ventilation fans, and a list of symbols (Figure 2).

Shipboard Firefighting Training from Scratch

SHIPBOARD FIREFIGHTING: THE BASICS

Figure 1. An Outside View of the Bow Section

Figures by author.

(1) The fire plan is at the ship’s entrance. (Photos by author.)

Figure 2. A Section of the Fire Plan

The positions on the ship are as follows: The bow is the forward end; the stern is the aft end; starboard (STBD) is the right side looking forward; port is the left side looking forward; inboard is toward the ship’s centerline, which runs from bow to stern; and outboard is away from the center line. On most American ships, lifeboats would be numbered #1 on the STBD and #2 on the port.

The frames of a ship are the vertical sections numbered from AFT to FWD or from FWD to AFT; the fire plan notes the distance between the frames. Some ships have one or more bow thrusters to push the ship from side to side; they must be off during water rescue operations. The bulbous bow on the FWD lower edge provides for more efficient sailing and can be an underwater hazard at the dock.

The crew can be a helpful resource when outside agencies are called to a ship. The officers are licensed, trained professionals who know the ship intimately and have the knowledge to handle most situations. During a general alarm, the captain or master is in overall command. The on-scene commander in the deck department is the chief mate, followed by second assistant mate and third assistant mate. The engine department is under the command of the chief engineer, followed by the first assistant engineer, second assistant engineer, and third assistant engineer. On most ships, the remaining department is the steward department, which operates the galley and serves the crew cabins. During a general alarm, the stewards are often assigned to assistance roles.

Confined Space Hazards

Sources of gas exposure on a ship can include diesel oil, heavy fuel oil, liquefied natural gas (LNG), carbon monoxide (CO) extinguishing systems, or any hazardous cargo. A ship has an abundance of confined space hazards. Firefighters and rescue personnel should be equipped with meters to test spaces for oxygen deficiency and CO. Insufficient ventilation has caused customs officers to be overcome while searching a vessel’s confined spaces for drugs. Additionally, CO from forklift and portable pump exhaust has overcome ships’ crews and longshoremen.

Electrical exposure is common, from the 440 volts of alternating current (AC) for auxiliary machinery to the 6,000 to 12,000 volts AC for some thrusters, motor generators, and air-conditioning compressors. Consider the amount of electrical power necessary for refrigerated shipping containers on a large container ship. Dust exposure is possible from a conveyor ship.

The Rescue Scenario

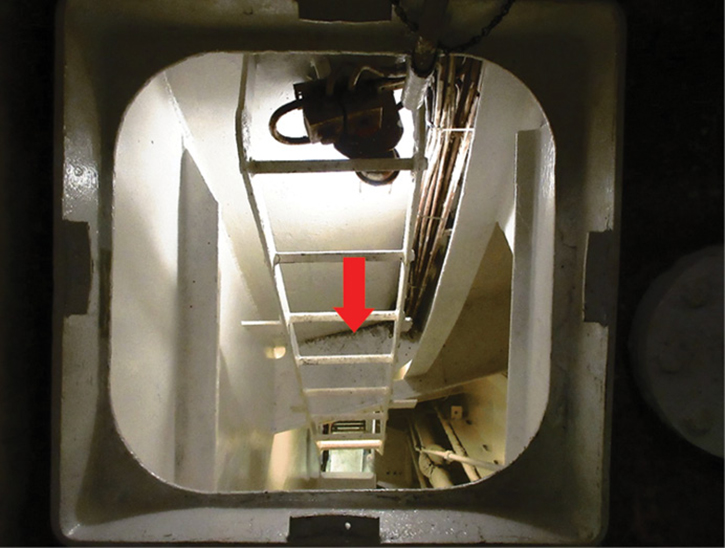

The rescue team arrived on Deck B at the vertical opening to the emergency fire pump room (photo 2). The pump room was 36 feet down the ladderway (photo 3). The team followed confined space entry procedures with self-contained breathing apparatus (SCBA) and gas monitoring. The fire plan showed a diesel oil tank in the vicinity, but diesel oil was not measured. Since the patient was unconscious, there was no issue with communicating in the pump room. The patient was accessed, packaged, and raised out of the hatch using a quadpod system that allows for adjusting the legs against the uneven side of the ship.

(2) The hatch on B Deck to the FWD fire pump room.

(3) The ladderway down from B Deck; it is 36 feet to the pump room.

During the rescue, the team directed air flow down the entry hatch, normally using a saddle to limit the obstruction of the hatch opening. The one unexpected event was exhaust air flow out of the entry hatch. The air had nowhere to go but back the same way it came in. The exhaust air did not register any hazardous gases on the team’s gas meters; it was believed to be stagnant air from the pump room.

Ventilation

The fresh air supply should match the exhaust air supply. Otherwise, ventilation will not be effective; it will either overpressurize the compartment or create a vacuum. Both conditions can result in a door opening explosively when unlatched. Every firefighter knows the positive effect of allowing gases to exhaust out of a roof or of using positive pressure to gain entry to a building fire. With a ship, ventilation is different: The compartments are usually airtight so ventilation in and out has to be provided.

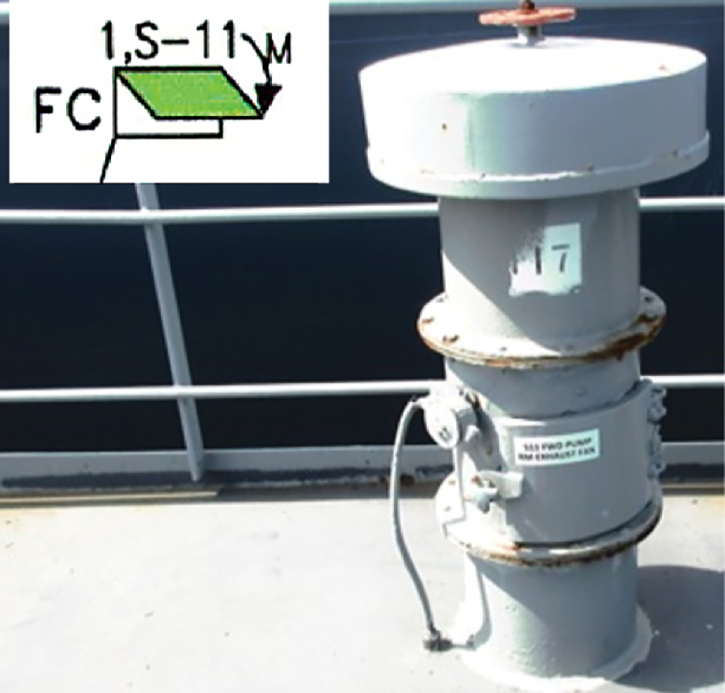

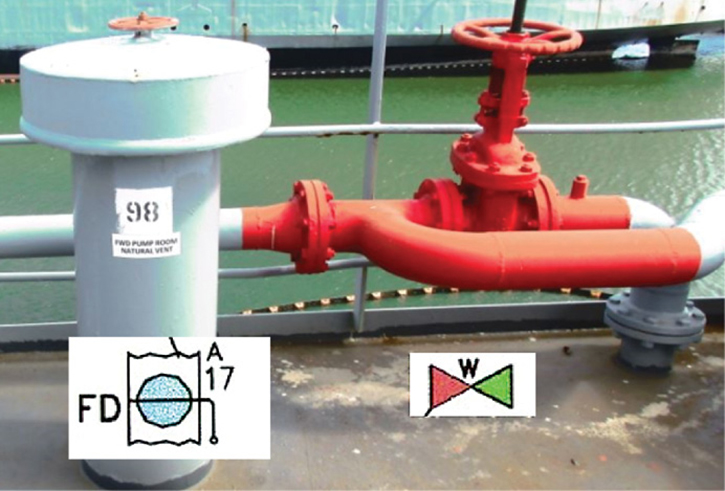

The fire plan showed an exhaust fan S-11 for the pump room on the upper deck port side. Also shown is the symbol for the fire closure or damper (photo 4). Photo 5 shows a natural vent on the upper deck STBD side. Damper controls are on the top of the mushroom covers of both vents. The switch for the fan is in the engine room (photo 6); it is unlikely the rescue team would turn on the fan without the help of the crew. Still, the rescue team can ask the crew to turn on the ventilation and to open the fire dampers on the exhaust fan and on the natural vent if they are closed. The pump room space can also be ventilated from the engine room. Four watertight doors are opened in the pipe tunnels, and the crew turns on the engine room supply fans.

Figure 3. Internal Layout of the Bow Section

(4) The pump room exhaust fan with the fire plan symbol for a fire closure for machinery spaces.

(5) The natural vent and fire main valve on the STBD side upper deck with symbols as they appear in the fire plan.

(6) The engine room control for the pump room exhaust fan.

A ship is a three-dimensional structure that can be very confusing. Patient extraction will be difficult in many places on a ship, such as from inside a tank, a fan enclosure, or a bilge. Although the ship’s crew is the most knowledgeable resource for information about the ship’s layout, the crew may be incapacitated, and the rescue team may need to find the ship’s fire plan and proceed on its own. Ventilation can be used to your advantage provided the rescue team understands the ship’s layout. Unlike a structure, a ship has few natural openings; therefore, ventilation must be controlled with dampers and fans.

In this case, the internal layout of the rescue area appears in Figure 3. The pump room’s design calls for the exhaust fan air to flow up on the port side and natural vent air to flow down on the STBD side. The fire dampers are provided to limit air or water flow in the pump room. If air flow from an external fan is directed down the B Deck hatch, the air has nowhere to go unless the fire dampers on the fan and vent are opened. Even if the exhaust fan were turned on, supplied air down the hatch can still flow past the open dampers on the main deck.

The exercise illustrated the challenges of operating on a ship and serves to show what factors to consider when attempting a rescue.

Author’s Note: The article was based on a training scenario provided by Captain Anthony Morley, Charleston (NC) Fire Department Technical Rescue Team R115.

Maryon J. Williams Jr., Ph.D., P.E., served as a volunteer firefighter for 20 years and was the captain of the high-angle rescue team and an emergency medical technician. He is an engineer with Condition Analyzing Corporation, which is engaged in surveying ships. Williams has degrees in electrical engineering from Georgia Tech and Rutgers University and has held teaching positions at Rutgers University and the Medical College of Georgia.