THROUGH THE SOUND BARRIER

APARATUS & EQUIPMENT

(All photos courtesy of Prince George’s County Fire Department.)

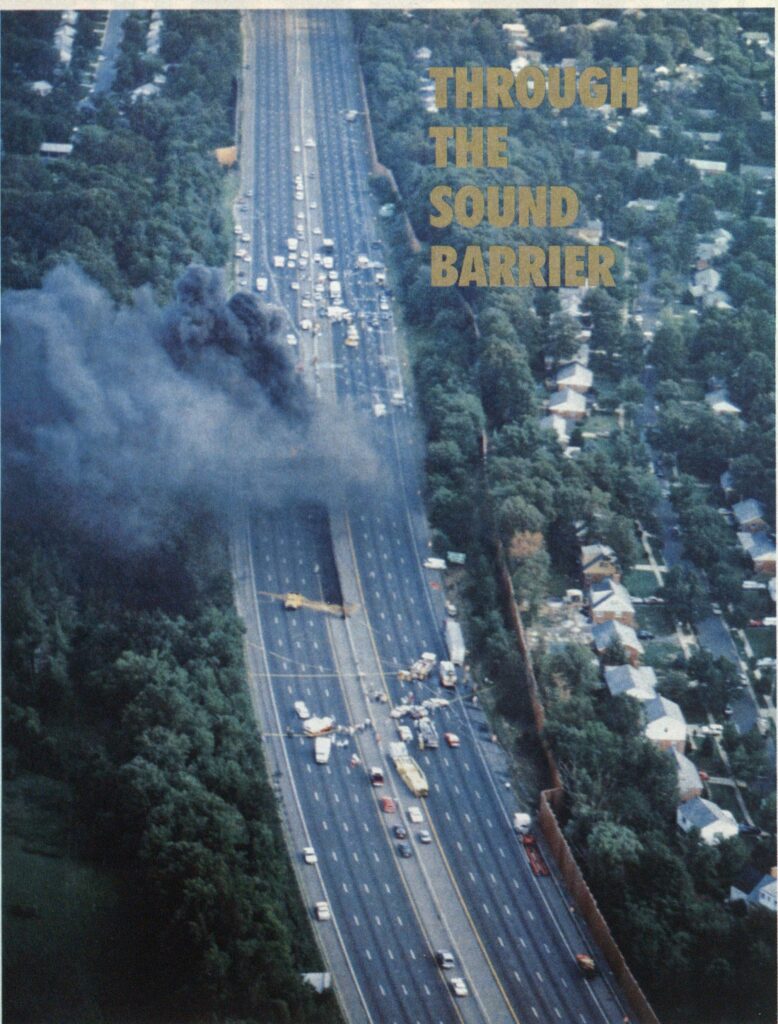

Without sacrificing community concerns, a Maryland fire department takes innovative steps to solve its water supply problems on a well-traveled stretch of highway.

IN RECENT YEARS there has been growing concern over the effects of noise pollution in and around the Washington, D. C. metropolitan area created by heavy vehicular traffic on congested highways. Noise pollution has become such a frustrating and annoying problem for area residents that it has prompted local, state, and federal agencies to seek ways to reduce the harmful effects of noise to acceptable levels.

In an effort to address such concerns, the Maryland State Highway Administration began construction of a sound abatement barrier system along Interstate Route 95 in several areas within Prince George’s County, Maryland. The fire department was quick to realize the project’s potential obstruction of an adequate water supply for firefighting.

This phase of the sound abatement barrier project was unique in that it was the first of three barrier projects scheduled to be constructed within Prince George’s County and the only one to be built entirely of heavy timber. The sound abatement barrier has three separate walls, totaling 10,424 feet in length. The walls are constructed entirely of heavy, laminated timber panels. Each panel is approximately 14 feet in width and ranges from six to 25 feet in height, depending on the topography of the terrain.

Since its completion, the sound abatement barrier has adequately reduced noise intensities in adjacent residential communities. However, the barrier has created a significant fire protection obstruction on a stretch of highway noted for major hazardous-materials incidents and fires. The fire department’s biggest concern was that the barrier would prevent the rapid establishment of a reliable water supply for emergency operations, particularly those requiring large-volume fire flows.

Under ideal conditions, firefighters spend a considerable amount of time establishing a reliable water source adjacent to limited-access highways. Now to reach existing water supplies would require more resources and even more time.

Given the urgency of the situation, Fire Chief M. H. (Jim) Estepp appointed a review committee to do the following:

- establish a formal line of communication with each of the principles involved in the design and construction of the sound abatement barrier project,

- reexamine and evaluate the fire department’s current and future operational needs and capabilities in the areas affected by the barrier system, and

- provide recommendations to resolve the problems resulting from construction of the barrier system.

WATER SUPPLY PROBLEMS

During the initial development phase of the barrier system, the State Highway Administration and design architects did not consider the fire protection limitations. Consequently, they did not have a plan for accessing the existing water supply sources adjacent to the highway.

The only access to the residential side of the wall was through four maintenance access doors, which serviced more than 10,000 feet of wall. The possibility of using these very limited openings was quickly eliminated—from a tactical standpoint, running hoselines through them would involve tremendous distances. The fire department was now faced with the task of identifying and developing alternative, reliable water supply sources.

SUGGESTED SOLUTIONS

Personnel from the first-due engine company conducted a comprehensive analysis of the problem in affected areas. They scrutinized scale maps of the affected areas and the adjacent residential communities that showed the location of the water supply sources. Their goal was to establish a cost-effective water supply source through the sound abatement barrier using the existing water supply system.

The personnel then went into the adjacent residential communities to identify the exact location of fire hydrants in relationship to the proposed location of the barrier wall. They took measurements along the most direct route to the wall, taking into consideration the natural terrain of the surrounding area and any man-made obstacles. They transposed this information onto a master scale map and were then able to compute the exact location of the closest water source and the travel distance to the barrier. Using this technical information, they could plot where to provide access points along the wall.

After identifying access points, the next step was selecting a specific method of delivering an adequate water supply through the sound abatement barrier. It had to be cost-effective and feasible from an operational standpoint.

Choices included extending existing water mains through the barrier, providing access openings to allow hoselines to pass through the wall, and installing hose connections through the barrier. The first was ruled out as too costly. Of the two remaining options, the state elected to install fire department connections at specified locations. The department would design the water supply connections to be cost-effective, easily fabricated, and durable. In addition to paying for these connections, the state also agreed to make identification signs to post at each connection.

The State Highway Administration chose the water supply connection option over access openings because it was concerned with maintaining the natural aesthetics and integrity of the wall system. The state agreed to bear all costs associated with the fabrication, installation, and identification of the connections.

BREAKING THE SOUND BARRIER

P. E. David Banwarth, chief fire protection engineer for the Prince George’s County Fire Department, was given the task of designing a suitable connection. He developed the concept of mating inlet and outlet fittings back-to-back, permanently installed on each side of the wall so that hoselines could be connected. His preliminary design consisted of a 2 1/2″ x 2 1/2″ x 4″ male National Standard Thread (NST) gated-wye connection attached to a 4″ threaded pipe to penetrate the wall and receive a 2 ⅛” x 2 1/2″ x 4″ female thread (NST) Siamese with dual clappers on the reverse side. A bolted collar would hold the device in place in the wall (see illustration).

The basic design, accepted and utilized by the state unchanged, was flowtested after installation using a typical range of expected gpm volumes. Tests up to 850 gpm flow measured friction loss in the fitting to be so small as to be insignificant. The testing involved using a ring gauge on both intake and discharge sides of the device while measuring the pressure (pitot gauge) of the discharge stream at various nozzle tip sizes (1 1/4″, 1 3/8″, 1 3/4″, 1 3/4″) on dual 3″ lines. Test results verified the efficiency of the device for normal usage. It is estimated that losses would likely remain minimal up to 1,200 gpm or more.

The connections were placed approximately every 1,600 feet along each of the walls. The connections located in the opposing lanes were offset, creating a staggered pattern in order to maximize coverage for both sides of the highway.

The design characteristics and flow capacities of the Siamese connections make this device extremely versatile during emergency incidents. The connections enable engine companies to establish a reliable water supply source to the sound abatement barrier connection independent of other engines operating on the interstate.

Members of engines positioned on the highway can easily establish a single or multiple supply line. The gated discharges on the connections allow them direct control over the water source. During protracted and dangerous emergency incidents involving hazardous substances, unmanned protective master stream devices may be connected to allow apparatus and personnel to withdraw to safer positions.

MARKED FOR EASY IDENTIFICATION

To help personnel locate the Siamese connections during emergency incidents, a simple identification and numbering system based on existing interstate mileage markers was adopted. To make these mileage markers more noticeable, the color screen was changed from the traditional green and white to a red number on a white background. The number on the mileage marker corresponds to a specific hose connection location. Thus apparatus responding to the residential side (supply side) of the barrier can reference response maps for the closest water source to a given incident on the highway.

To ensure that both supply units and receiving units operate from the same Siamese connection, signs indicating the location of the connection are mounted at the top of the barrier wall on the residential side of the barrier. These identification signs bear the same mileage number as those on the opposite side of the wall.

A WORTHWHILE PROJECT

The Siamese connections allow the fire department to access existing water supply sources and reduce the length of hoselays required to do so. Moreover, they have lessened the need for an excessive number of emergency vehicles, thus reducing the risk of injury to fire department personnel.

The overall cost of the design, fabrication, and deployment of the 10 Siamese/ gated-wye connections in the first phase of this project was approximately 510,000. We consider this expense to be far less than what would have been incurred had the barrier wall been extensively modified or a new hydrant system installed.

Since the system’s inception, the idea of using siamese/gated-wye connections has been adopted by other local jurisdictions in the Washington metropolitan area. The Prince George’s County Fire Department has taken an innovative approach in identifying and solving this very difficult problem. The system has proven to be effective for us and we recommend it as a viable alternative for departments experiencing similar problems.