THE PCB/PVC CONFUSION CONTINUES TO SPELL CAUTION FOR FIRE FIGHTERS

HAZARDOUS MATERIALS

While controversies rage over the toxicity levels of PCBs and PVCs, with both sides presenting facts and figures for the consideration of consumers and governmental agencies, it’s still the fire fighters who are forced to work in these hazardous chemical environments.

Dioxin. A byproduct of the manufacturing process for Agent Orange, a widely used defoliant during the Vietnam War, dioxin is considered by scientists to be among the most toxic chemicals known to man.

Fire fighters may be more familiar with dioxin in another form—polychlorinated biphenyls (PCBs). When exposed to intense heat and oxygen, PCBs break down into dibenzofuran and dioxin, the same form of dioxin found in Agent Orange.

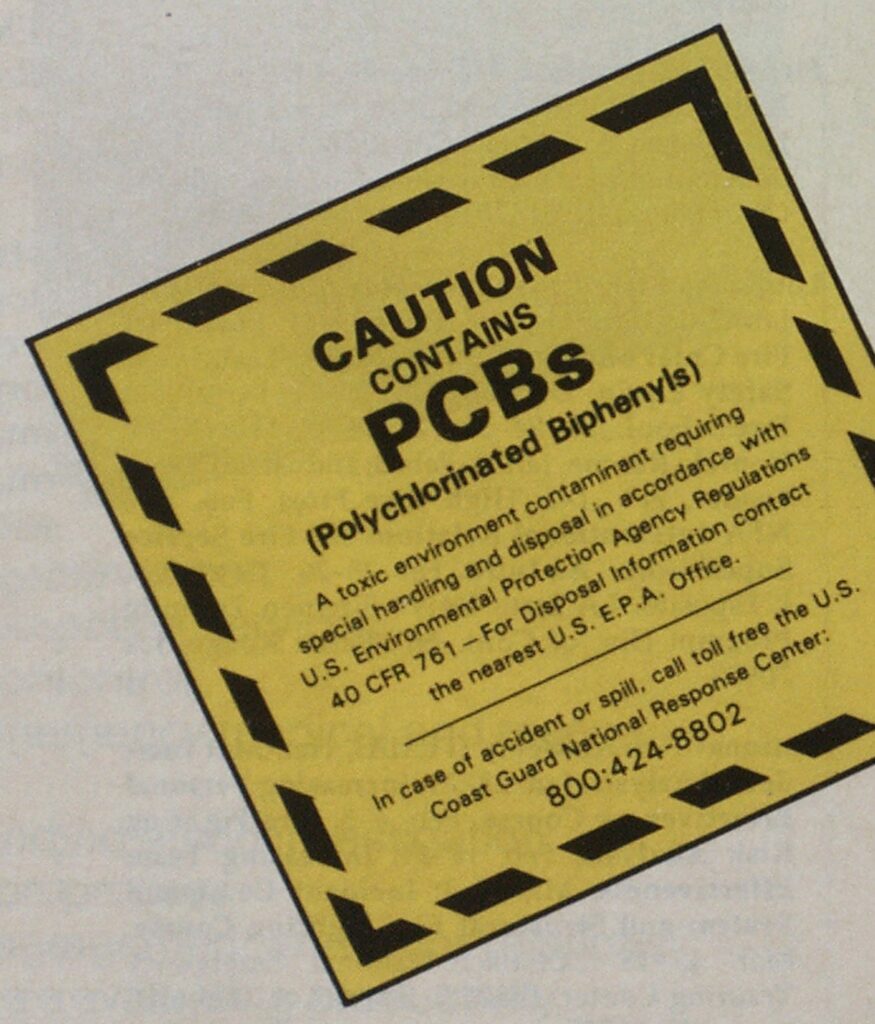

Although the EPA banned the manufacture, processing, and use of PCBs “except in a totally enclosed manner after July 2, 1979,” there are an estimated 750-million pounds of this synthetic chemical still in use throughout the United States. Economic considerations prompted the EPA to allow’ older industrial equipment containing PCBs to be operated “for the remainder of their useful lives.”

Evidence that equipment containing PCBs is still in use surfaces from time to time.

An 18-story office building in Binghamton, N.Y., that has been closed since a Feb. 5, 1981, electrical transformer fire, is undergoing a massive PCB cleanup. The cleanup is not expected to be completed until at least mid-1984, said a fire department spokesman. About 180 gallons of PCB coolant spilled and some of it vaporized, spreading PCBs, dioxin and dibenzofuran throughout the structure’s ventilation system.

In Maplew’ood, Minn., the HillMurray High School suffered PCB contamination June 22, 1982, when an electrical transformer overheated, releasing vaporized PCBs into the hallways. Five-year tests are being run on fire fighters who were exposed to the toxic chemical.

Electrical transformers are not the only potential PCB threat. Capacitors, boilers, mining equipment, hydraulic systems, electromagnets, railroad transformers, and natural gas pipeline compressors are just some of the other PCB harbors.

Exceptions to the 1979 PCB restrictions are based on the EPA having determined that in totally enclosed equipment, PCBs “present no unreasonable risk to human health or the environment” and that “exposure to PCBs from closed and controlled . . . processes is so low as to be unmeasurable for all practical purposes.”

Unfortunately, “all practical purposes” doesn’t include fire incidents.

PCBs enter the body by ingestion, absorption through the skin and inhalation. Once taken into the body, PCBs circulate in the blood stream and are stored in fatty tissue and organs, including liver, kidneys, lungs, adrenal glands, brain, heart and skin.

Although there are conflicting reports about the PCBs causing cancer in humans, PCBs have been known to cause eve irritation, headache, fatigue, chloracne (painful and disfiguring acne-like skin eruptions that can appear w’eeks or months after initial exposure and last up to 15 years), nausea, vomiting, wreight loss, jaundice, edema, digestive disturbances and liver dysfunction. According to the book Dangerous Properties of Industrial Materials by N. Irving Sax, “Where liver damage has been severe, (the victim) may pass into coma and die.”

According to the Federal Register, “The EPA has concluded that. . . there is a potential for reproductive effects and developmental toxicity as well as oncogenic effects (tumors) in humans based on animal data.”

Because of the certain and uncertain effects of PCB exposure, fire fighters must take extra precautions when faced with a PCB incident.

Knowing where PCB equipment is located before an incident occurs is important, as is close supervision and technical assistance from concerned agencies (EPA, electrical companies, EMS, etc.) during an incident.

Full protective turnout gear and SCBA are mandatory when operating at a PCB incident or even if PCBs are suspected. The hazard area (hot zone) must be isolated and unauthorized personnel denied entry.

Since hazardous material incidents frequently occur at locations where communication is difficult, it is important that every effort be made to keep a phone line open so that the material shipper can make contact to provide guidance and assistance.

To extinguish a PCB fire, dry chemical, carbon dioxide or foam should be used. There is the possibility of pollution from fire control runoff, and diking procedures must be maintained.

In case of chemical contact, skin and eyes must be flushed immediately with running water for at least 15 minutes. Contaminated shoes and clothing must be removed and isolated, and all tools and SCBA used during operations should be collected and bagged.

Members who were exposed to PCBs should thoroughly shower with soap and water, and all apparatus used at the scene should be washed and rinsed before being returned to the station.

Fire fighters not directly involved in the emergency operations should stay in a staging area upwind of the incident. Eating, drinking or smoking in the contaminated area is prohibited.

Those injured at a PCB incident should inform hospital personnel about their having been exposed to PCBs before entering the hospital.

PVC

Although concrete evidence pointing to possible carcinogenic effects of PCBs in humans may be lacking, evidence abounds on both sides of the controversial issue of polyvinyl chloride (PVC) toxicity.

Anything that burns gives off toxic gas. The question lies in the degree of toxicity encountered when PVCs decompose in fire.

It must be acknowledged that the main attack against PVCs is being launched by manufacturers of competitive materials, metal, aluminum, steel, wood, cement.

According to one report, ‘There is mounting evidence that decomposing plastics contributed to the vast majority of fatalities in such . . . tragic fires as the Beverly Hills Supper Club near Cincinnati, Ohio, (1977) where 165 people died; and the MGM Hotel in Las Vegas, Nev., (Nov. 1980) where 84 lost their lives” (see Fire Engineering, March 1981).

It was reported that in the MGM fire, plastic materials, including plastic plumbing pipe, have been implicated in a number of deaths, many of which occurred more than 20 floors above the fire.

In the Beverly Hills incident, it was reported that there were more than 4000 feet of PVC-coated electrical cable above one crowded room. A short in the electrical system heated the plastic, causing it to decompose and release clouds of toxic smoke. A subsequent trial against PVC manufacturers decided that the producers had a duty to warn of the dangers associated with PVC products.

Due to PVCs cost effectiveness, durability, fire retardancy and corrosion resistant and dielectric properties, they are used worldwide in the manufacture of plastics. PVCs are used in upholstery, wall coverings, flooring, electrical conduits, plumbing pipes, house siding, food packaging, medical supplies, and more.

The primary product of PVC combustion is hydrogen chloride. Upon contact with moisture, such as in the eyes or lungs, hydrogen chloride becomes hydrochloric acid. “We know that death in PVC exposure is attributed to sensory and pulmonary irritation due to hydrogen chloride production,” says Dr. Merritt Birky, director of research for the Foundation for Fire Safety, in an ISFSI report.

Tests done at the University of Pittsburgh’s toxicology lab determined that less than a half-pound of decomposing PVCs in a typical hotel room would kill within 10 minutes. A typical hotel room contains up to 20 pounds of PVCs.

Jack Snell, director of the Center for Fire Research at the National Bureau of Standards said in a Feb. 1983 Fortune article that “Plastics would not create a significant additional hazard to life. Typically it’s the contents of a building— in contrast to construction, plumbing, and electrical materials— that represent the largest fuel load. You would need a large fire before the conduit became involved, and by that time the burning contents of the room would have caused the occupants to succumb.”

The PVC toxicity battle is basically waged for the benefit and backing of consumers (civilians). But whether it’s hydrogen chloride or carbon monoxide or any other toxic gas released at a chemical incident, it’s the fire fighters who are most prone to suffer from the effects.

Dr. Robert Dyer, who appeared on a CBS morning news show late last year, conducted a study on PVCs. As part of the study, Dyer followed over 200 fire fighters who were exposed to PVC combustion products, and Dyer believes that PVCs present a serious health hazard.

Polychlorinated Biphenyls

Polychlorinated biphenyls (PCBs) are made up of 209 individual man-made chemical compounds, individually referred to as chlorinated biphenyl congeners. About 100 of these PCBs are used commercially.

PCBs have a mild hydrocarbon odor and range in consistency from heavy oily liquids to waxy solids. PCBs vary in composition and degree of chlorination; the higher the chlorine content, the more toxic PCBs are likely to be.

Depending on the composition, PCBs have a boiling point between 340° and 375°, a flash point of 383°, and a density of 1.44 at 30°.

Because of PCBs’ high boiling point, high degree of chemical stability, low solubility in water, low flammability and low electrical conductivity, these synthetic chemicals are ideal for many commercial uses.

PCBs were discovered in 1881, but it wasn’t until 1929 that their benefits as industrial chemicals were founded and commercial manufacturing of these compounds began.

The dangers of PCBs were first recognized in 1968 when more than 1000 people in Yusho, Japan, used rice oil that had been contaminated with 2000 to 3000 ppm PCBs leaking from a heat exchanger. The victims developed skin lesions, eye discharges, fatigue, cough, nervous disorders and hyperpigmentation of the skin, nails and mucous membranes. According to an EPA report, “. . . there is evidence that there was an increased rate of cancer among Yusho victims who have died since 1968.” In 1972, the Japanese government virtually banned the production, import and export of PCBs.

Polyvinyl Chloride

Polyvinyl chloride (PVC), an organic polymer, is produced by the polymerization of the vinyl chloride monomer, a flammable volatile gas. The monomer mixes with catalysts to produce long chain PVC resins.

The solid PVC resins can be produced in any color and can be converted to pellets, powders, pastes or film and then formed by extrusion or molding processes into finished products. These products can be as rigid as pipe or as flexible as upholstery. This petroleum-based plastic is strong, abrasion-resistant, lightweight and chemically inert.

Since PVCs break down differently than they are formed, the main product of PVC combustion is hydrogen chloride gas rather than vinyl chloride monomer. PVCs also release carbon dioxide, carbon monoxide, and small amounts of phosgene, benzene, toluene and mixed hydrocarbons.

PVC tubing was first pioneered in Germany in 1923. During World War II, it served as a substitute for electrical wire and cable insulation in the U S.

Dyer determined that PVCs affected many of the fire fighters’ eyes and throats, and caused headaches and interior chest pains. “If (the fire fighters are) followed closely enough,. . . about 15 percent develop the cardiac arrhythmia (irregular heartbeat), which is diagnostic of what hydrogen chloride does on the myocardium (the middle muscular layer of the heart wall).”

Stringent emergency procedures are spelled out in the Hazardous Materials Emergency Response Guidebook for fire fighters faced with a PVC incident. First and foremost, positive pressure SCBA and full protective clothing must be worn.

Emergency personnel further are warned to stay upwind and keep out of low areas. Areas endangered by the gas should be evacuated and the hazard zone isolated and unnecessary people denited entry. For emergency assistance, CHEMTREC or Hazardline should be called, and in case of water pollution, local authorities should be notified.

As with PCB fires, dry chemical, carbon dioxide or foam should be used at a PVC fire, and containers exposed to flames should be cooled with water from the side until well after the fire is out.

In the event of a spill or leak, the Emergency Response Guidebook advises using water spray to reduce vapors, but warns against putting water on the leak area.

Contaminated shoes and clothing should be removed and isolated, and in the event of material contact, skin or eyes must be flushed immediated with running water for at least 15 minutes.

The Emergency Response Guide also warns that inhaled vapors may be fatal and that victims should be kept under j observation, as the effects of the chemical may be delayed.

According to The Vinyl Institute, the PVC industry has grown by approximately 900 percent in the last 25 years. With 5.7 billion pounds produced each year in the U.S., PVCs will continue to penetrate the construction, transportation and packaging markets over the coming decades. Add to this an estimated 20 billion pounds of PCBs still in storage, and it’s evident that fire fighters will be faced with a high potential of serious incidents involving these two chemicals for many years to come.