THE GREAT BEND EXPLOSION

For many years Great Bend, Kansas has been known for its oil field production. Despite dwindling reserves over the past few years, there are still a number of oil service companies in and around the city. One such company is Wire Tech Services, Inc., which on the morning of October 30, 1989 was the site of an unusual incident that tested the Great Bend Fire Department and bore substantial lessons.

The weather that morning was very cool, with a sharp wind out of the northwest. As I prepared to leave my house for work at about 0740 hours, my lights flickered for a moment; 15 to 30 seconds later they flickered again. Shortly thereafter I was notified by pager of an explosion and fire at 919 10th Street, the address of Wire Tech.

INITIAL RESPONSE

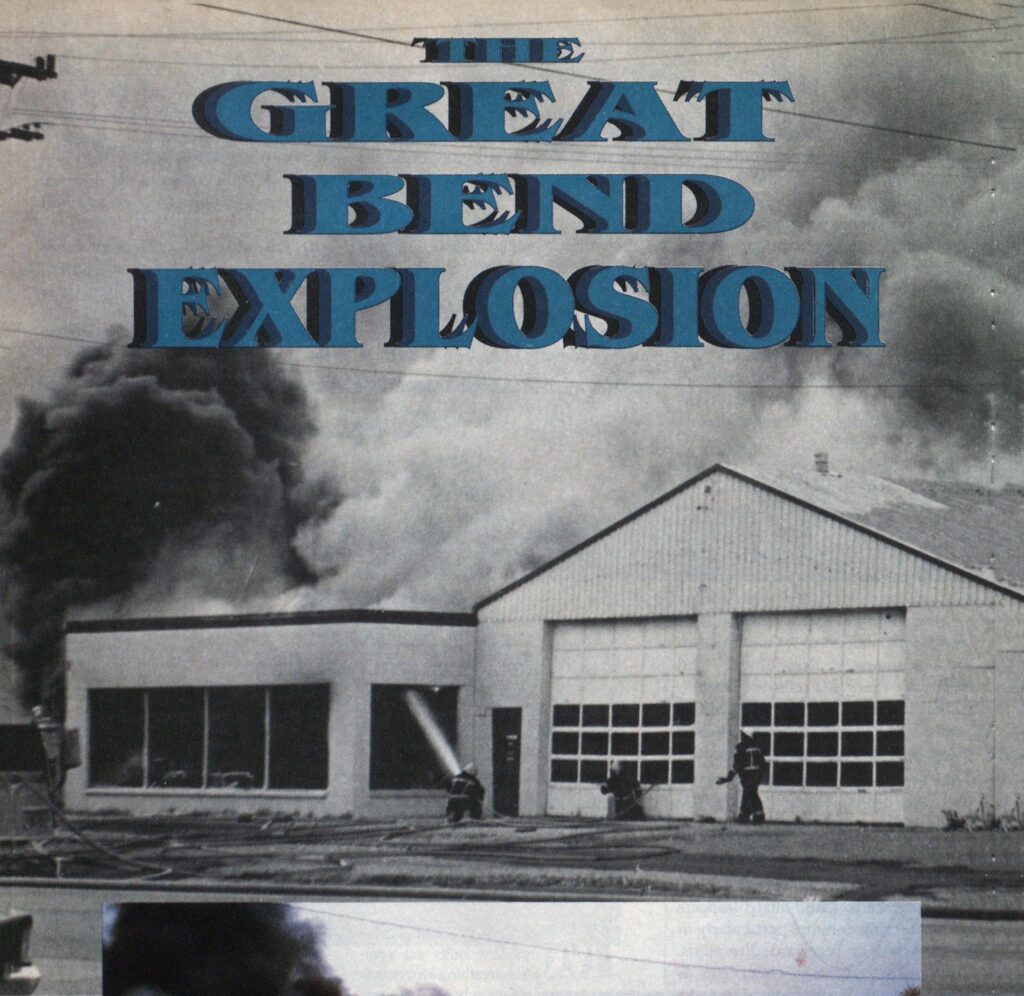

While responding I noticed heavy black smoke in the area of the fire. On arrival I found the Wire Tech building, a masonry and steel structure approximately 150 by 200 feet, fully involved in fire and emitting heavy black smoke. Debris from the building was lying all over the area. The police department was rerouting traffic from the area and handling crowd control. Fire department personnel were advancing on the fire with handlines with the intention of mounting an interior attack. As I stepped out of my vehicle I heard small explosions occurring inside the structure.

I conferred with Assistant Chief Marion Root, took command of the incident, and established the command post at the northeast corner of the intersection. We confirmed that the two employees who had been in the Wire Tech building at the time of the explosion were assisted off the premises and rendered aid by a Great Bend firefighter who lived nearby. Before their removal to a hospital by the first-responding fire department ambulance, they were able to confirm that there were no other employees in the building.

Great Bend Police Chief Dean Akings and Barton County Sheriff Jim Daily arrived shortly after me and reported to the command post. Soon thereafter one of the owners of Wire Tech Services arrived and reported that the building contained hundreds of shaped charges. I immediately ordered all firefighters to withdraw from the building and switch to a defensive outside attack on the fire using monitors. Then I requested evacuation of the properties in a onequarter-mile radius; this distance was determined with due regard for the types and quantities of explosives involved.

OPERATIONS

Evacuation. Police Chief Akings offered to handle the evacuation. He dispatched officers to make the notifications, requested buses from the school district to pick up evacuees from two designated areas, and designated the city recreation center as a shelter. In further conversations with the business owner we discovered that there were also radioactive isotopes in three different locations inside the structure, and the evacuation areas to the east and south were increased to one-half mile as a precautionary measure, as they were residential and were downwind from the fire.

Mutual aid, interagency response. I knew this was going to be a lengthy incident. I called the fire departments from the cities of Hllinwood, Claflin, and Hoisington for mutual-aid assistance to cover any emergencies that might develop while we were dealing with the Wire Tech operation. These cities, each approximately 10 miles from Great Bend, dispatched units immediately. I requested the assistance of the county emergency preparedness director; the Bureau of Alcohol, Tobacco and Firearms (AIT); ordnance personnel from the U.S. Army base at Fort Riley, Kansas; the state fire marshal’s office; and the American Red Cross.

Firefighting operations. Since our fire department shifts relieve at 0800 hours, we were able to place secondalarm units on-scene shortly after the first-arriving companies. I divided the foreground into two operational sectors—north/east and south/west —and assigned assistant chiefs Root and David Christiansen to command them.

Fire department efforts to contain the fire and protect exposures were successful from the outset. Our immediate exposures were a communications company attached to the fire building on the west side and a small neighborhood bar directly west of the communications company. The bar address was also a residence, and its one occupant was evacuated immediately following the blast and fire. To the south of the fire area, approximately 200 feet from the Wire Tech building, were trailer homes. Many of these, particularly those closest to the building, sustained damage from the explosion as well as the debris and devices propelled by it. Immediately east of the structure was a large storage compound, most of whose contents sustained damage from the explosion as well.

10th Street is the name given to state highways 56, 96, and 156 as they pass through Great Bend. It’s the city ’s main east-west thoroughfare. Wire Tech was located on the south side of 10th Street. On the north side are commercial structures, some of which were occupied at the time of the explosion; fortunately no one was injured. These structures, mostly of steel construction, also sustained damage. A pickup truck parked on the north side of the street directly across from the Wire Tech building looked as though it had been shot with a machine gun.

Reconnaissance. Our crews were finding numerous unspent explosive devices lying in the streets and yards surrounding the Wire Tech building. Since Police Chief Akings had access to a fixed-wing aircraft, he suggested that we use aerial reconnaissance to get a better idea of how far the explosives and debris had actually traveled in the blast. We instructed the air crew to take both stills and video. Aerial photos showed that the explosion direction was southeast, and this was where most of the devices eventually were found.

Public information. After gathering more information about the explosives from the Wire Tech owner, I held a news conference and asked the media for their assistance in warning the public about the explosive devices. They were encouraged to take photos and display them to the public so that residents would be better able to identify the devices and notify the police, sheriff, or fire department. Police Chief Akings took several of the spent devices to an assembly of local elementary schoolchildren; there he explained what had happened, showed them the devices, and answered their questions. He instructed them to tell their parents or some other adult immediately upon encountering such an object and not to touch it.

Fire knockdown. Meanwhile, after about an hour of firefighting from a defensive stance, our forces were successful in knocking down the majority of the fire. A fully protected member using proper dosimetry equipment checked radiation levels both outside and inside the Wire Tech structure. All readings taken around the three “pigs” (lead containers for radioactive isotopes) were normal —the containers had not been breached. A firefighting team then was ordered into the structure to complete fire extinguishment. The fire was out at approximately 1000 hours.

Cleanup. Our crews soon learned that putting out the fire was the easy part. The massive cleanup—finding and safely disposing of every explosive we possibly could—was still to come. We were fortunate to have had excellent interagency cooperation. Several oil field workers—one a licensed explosives handler—agreed to serve as command post advisors. Five agents from the Bureau of Alcohol, Tobacco and Firearms assisted in device recovery and assisted investigators from the State Fire Marshal’s Office in determining origin and cause. The city’s public works department donated needed equipment and manpower. These organizations, in addition to those mentioned earlier, made the difficult task as smooth as it Could be.

At approximately 1200 hours we held a briefing for all participating agencies at offices offered to us by a local business. We used this space as our command post for the cleanup/ overhaul/investigation operations. We agreed that several sweeps of the area on foot were necessary to account for the vast majority of scattered live and spent explosive devices. This had to be accomplished before we could send the evacuees home and open the area up to traffic.

We divided the one-square-mile area surrounding the blast area into six sections. Each of six teams was assigned a sector. Each team was accompanied by ordnance or ATF field personnel as a safety precaution, and each carried a large plastic barrel into which they placed found devices. Before conducting the search the teams were briefed by the command post explosives expert on how to determine if a device was spent. All unspent devices were to be treated with extreme care. We also had found pieces of primer cord scattered by the blast, so personnel were instructed to place them into the barrels as well.

A city dump truck loaded with a foot of sand was brought to the scene of the incident and placed inside the compound. This was used to hold the plastic barrels brought back to the scene by the search parties. They had found debris as far as one-half mile from the explosion.

Investigation and overhaul. Scene investigation and overhaul commenced immediately after our noon debriefing. Removal of explosive devices from the debris coincided with the investigation, and the process was tedious and slow. Two firefighting crews manned charged hoselines throughout the entire overhaul phase. A crane was brought in to remove trucks and heavy debris, and the radioactive material was removed from the pigs by qualified, fully protected personnel; placed into another approved container; and transported offsite to another company that performs the same services as Wire Tech.

Initial reports from investigators confirmed the Wire Tech owner’s belief that there were two magazines of explosives in the garage area of the building. Both were Type 2 metal indoor magazines as described by ATF and met that agency’s regulations for storage and construction. The first, approximately two-foot-square by two-foot-high, was designed to hold 20 pounds of explosives; the second, approximately three-foot-square by four-foot-high, was designed to hold 50 pounds. The smaller magazine was intact. It contained blasting caps and primer cord and was removed from the premises. The larger magazine, containing about 1,100 shaped charges and an undetermined amount of primer cord, was completely destroyed by the blast. Approximately 650 of these were recovered from the area sweep, leaving 450 that had shrapneled or were unaccounted for. In the past year 30 devices were found by civilians, half of which were unspent. These were handled and disposed of without incident.

The explosives magazines were situated on the concrete floor in the southeast portion of the Wire Tech building. Nearby were two logging trucks—heavy-duty, 10-ton field units that carry explosives, radioactive isotopes, and expensive equipment to measure seismic readings. Investigators found an 18-inch-deep by threefoot-square crater at the spot where the larger Type 2 magazine had been located prior to the explosion. One of the logging trucks was moved sideways a distance of 15 feet from the force of the blast.

Investigators believe there is a strong possibility that had the Wire Tech employees inside the structure at the time of the blast been anywhere else in the building, they would have been killed. As it was, the logging truck shielded them from the explosion. One of the employees stayed overnight in the hospital and the other spent approximately two days there. Their injuries consisted mainly of minor bruises and temporary hearing loss.

Investigations determined that the cause of the explosion and ensuing fire was a leaky natural gas connection on one of the building’s overhead heaters. The gas accumulated at the peak of the structure and then banked down to the overhead heater, whereupon it found the pilot light and was ignited, producing a small explosion. This explosion somehow dislodged one of several “loaded guns” (used for enlarging oil wells, they’re two-inchdiameter steel pipes with holes into which are fixed shaped charges; primer cord is strung from the charges up the length of the pipe and the assembly is then lowered into the oil well, ready for detonation) from either the logging truck or the loading rack. The loaded gun detonated, sending a piece of shrapnel into the magazine, thereby causing the second, larger explosion. Witnesses testified that they saw two separate balls of fire roll out of the structure.

10th Street was not reopened until 1700 hours that evening. The fire department maintained control of the property for an additional 36 hours to complete the investigation and to ensure that as many devices as possible were accounted for. The day after the incident ATF agents and a bomb technician from the Wichita Police Department brought the remaining devices to Great Bend’s old landfill and detonated them.

LESSONS LEARNED/REINFORCED

This incident reinforced the importance of a proactive fire inspection program—looking for hazards before they occur. City ordinance prohibits the storage of any explosives inside city limits. Inspections performed after the incident found two other businesses to be in violation of the ordinance, and they were required to remove their explosives to other locations (outside of city limits).

The state highway running through Great Bend is heavily traveled by hazardous-materials shippers. It’s almost a miracle that a tanker wasn’t in front of the Wire Tech building when the explosion occurred. Flammable liquids really would have multiplied our problems.

- We realize that firefighter knowledge increases firefighter safety. An interior attack on the Wire Tech fire could have been disastrous, and we were very fortunate that none of our firefighters were injured. In July 1990 the Great Bend Fire Department initiated an in-service fire inspection program, and our firefighters have increased their knowledge of the occupancies and the hazards inside them. The more we can educate our firefighters on the hazards inside a structure, the better we will be able to handle such hazards.

- We realized that our knowledge of explosive devices was limited. We have studied a videocassette produced by an explosive devices manufacturer and we attended a class given by one of the oil service companies so that our personnel could be better trained as to what to expect of these hazardous materials.

- Public support is vital to our fire prevention programs. Soon after the incident, Great Bend residents be-

- came very concerned with and involved in the explosives issue and we received quite a few calls about people storing excessive amounts of black powder and so forth in their homes.

Just a few months ago another company requested storage of approximately 500 pounds of explosives in a Type 1 magazine just outside the city limits, but the joint city/council planning commission denied the request. I attribute this to public reaction from seeing what 50 pounds of high explosives can do when detonated and trying to imagine what 10 times that amount would do. Of course, we don’t suggest setting off high explosives in the center of town to get the message across, but a creative, hardhitting fire prevention program could go a long way to improve fire safety in your community.

- All responding agencies realized the effectiveness of the incident command system as a scene management tool. Since the incident all fire department members have been trained in

- the National Fire Academy ICS course, and training for other agencies in the Great Bend vicinity is scheduled for early 1991. Moreover, the countyemergency preparedness plan worked well in the Wire Tech incident.

- Interagency cooperation is tantamount to the success of large-scale incident response. At the time of the Wire Tech incident, I had been chief of department for only 30 days and didn’t know what type of cooperation I would receive from other departments and agencies. The response was great. I received assistance from agencies of every level. If every fire chief received the support that I did on that day, their jobs would be much easier during times of emergency, when such support is crucial.

- Some of our future plans that grew in part from response to this emergency include the implementation of NFPA’s 704M marking system for fixed sites and expanded training for our personnel in the area of hazardous materials.