TEN KILLED IN KOPPER’S BLAST AND FIRE IN KEARNEY

AN EXPLOSION of vapors, resultLing from a combination of circumstances at the Kearney, N. J., plant of the Koppers Coke Company, on May 17, 1948, resulted in the death of ten men and started a fire which threatened not only the vast Kopper’s plant, but an entire industrial area.

The Kopper’s plant is part of the company’s tar-products division and covers five acres of ground along the Hackensack River, about 500 yards from the Newark Turnpike. A dozen buildings of varying size and type are sprawled over the terrain, including the huge blast furnaces, and a condenser building, which measures 250 feet x 400 feet. It is said that approximately 9,000,000 gallons of tar oils and other fluid petroleum products are stored in the area. The plant is reputed to be the company’s largest installation in New York’s Metropolitan district. About 400 employees were at work at the time of the disaster, but only those trapped in the locker rooms on the second floor of the combination laberatory and machine shop, known as the service building, were casualties.

As in many similar industrial installations, there is a heavy concentration of flammables in storage or being processed, in close proximity with combustible structures in the Kopper’s property. The plant is reported well equipped with approved safety devices and plant personnel are said to be trained in coping with run-of-the-mill fires that are peculiar to this type of industrial enterprise.

What, or who was to blame for the initial blast will probably never be known because the men who were concerned, and who might have furnished the clues, all died in the furnace heat of the fire that followed the explosion. Investigation by the Kearney Fire Department, Chief William Wandras, and Kearney Police and plant officials have established certain facts which point to human fallibility as the primary source of the trouble.

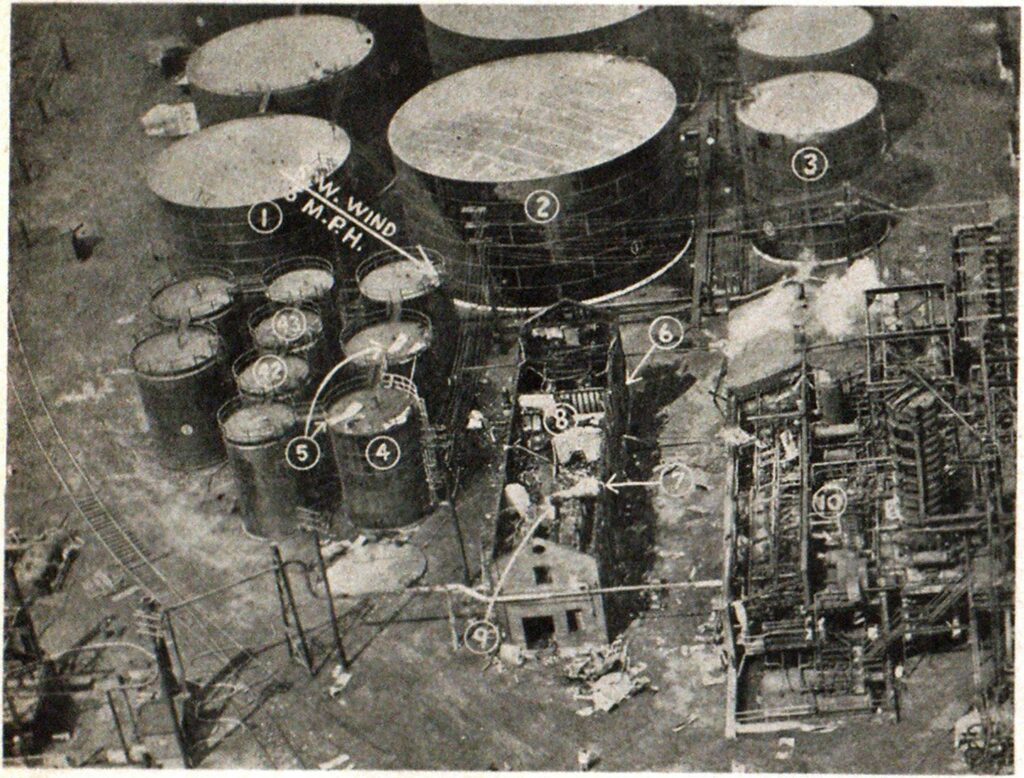

Reference to the photograph below shows a battery of tanks located north and east of the two-story service building, to the right of which is situated the condenser building (only partially shown).

Most of the tanks shown in the photograph were of 30,000 gallons capacity each and contained tar oil, or “drip oil.” Two of these tanks, most prominently involved in the disaster,—Nos. 42 and 43, were being steam treated at the time. These tanks are equipped with steam coils in the bottom for heat-treating the tank contents to a consistency that will facilitate their transfer. The conclusion reached by investigators is that in some way the steam treatment was misapplied for a considerable period of time prior to the explosion, resulting in overheating of the contents with consequent increase in vaporization and building up of vapor pressures.

Tanks 42 and 43, it is reported, contained drip oil, having a flash point of approximately 100 deg. F as compared with tar oil, stored in other tanks, which has a flash point somewhere between 350 and 600 deg. F.

These tanks are fitted with regulation safety vents and manholes but have fixed wooden roofs. It is understood that, as pressures built up, the vents opened and released the highly flammable vapors, which spewed forth in the form of fine spray where they were carried by the light breeze (said to have been about 5 MPH at the time) over the adjoining service building toward the condenser building, to its north, which was being operated at the time.

Just how much the weather conditions that evening contributed to the outcome is problematical, but it is the opinion of some authorities that the prevailing high humidity, without rain, helped to retard dissipation of the fumes and vapor as they reached the open air from the tanks. These fumes and vapors, being heavier than air, settled over the service building and occupied the area between it and the condenser building.

Burning Vapors Engulf Service Building—Trap Occupants

At 11:26 P.M., ignition from an undetermined cause, touched off these vapors which had lodged in the lower level of the run-down room in the condenser building, causing a terrific explosion and stopping all clocks in the plant. This blast took off practically the entire corrugated iron roof of the huge condenser building, scattering sections over a wide area (see photograph). Almost immediately, the service building was enveloped in flames, trapping its occupants, most of whom were disrobed, preparing for showers at the time. Of the ten irien, nine immediately succumbed to the flames; the tenth managed to make his exit by way of the fire escape at the front end of the structure, his clothing afire, but he was so badly burned that he died later.

The burning vapors flashed back to No. 43 tank, reported to be their chief source and this tank and No. 42 were ignited at the top, while the entire 150foot long service building was transformed into a roaring furnace. Fire also attacked a part of the condenser plant.

The concussion of the blast was felt in some places 15 miles distant. Residents of upper Manhattan caught the tremor and observed the corresponding flash in the sky. Two workmen, walking on the river bank several hundred feet distant, were blown into the river but escaped without more than the ducking. Excited persons over a wide area pulled fire alarm boxes. Fire, police headquarters and newspapers were deluged with inquiries into the trouble.

Prompt and Effective Work of Fire Fighters

The Kearney Fire Department received the first alarm from the plant at 11:29 and immediately responded with three engine and one ladder companies, under command of Fire Chief William Wandras.

Chief Wandras had proceeded but a short distance en route to the fire when he caught the full significance of the flare in the sky—a different glow from that which normally characterizes the night operations of the big plant. He at once stopped his car and at 11:32 notified headquarters by telephone to send in a second alarm. Upon his arrival at the fire ground a few minutes later, after a quick size-up, he ordered a third alarm, calling aid from Jersey City.

These alarms brought into action five engine and one ladder companies from Kearney and two engine companies— 7 and 15—from Jersey City under the command of Battalion Chief Duffy. Although Harrison, Newark and other city fire departments stood fast, ready to aid Kearney, they were not needed. One Kearney engine and ladder company were left to cover the town and one company remained to protect South Kearney.

(Continued on page 416)

Flammable Liquid Fires

(Continued from page 372)

Water Fog Effective

Upon arrival, Chief Wandras and his forces found the two-story service building entirely involved and fire emitting from the two storage tanks. A portion of the condenser building was also burning. Radiated heat threatened the remaining storage tanks in the immediate area.

No amount of water would have enabled firemen to reach the trapped workers in the locker rooms and they were all dead before the arrival of the Kearney firemen, who immediately turned their attention to preventing extension of the fire.

Hand lines were stretched, some from hydrants in the plant grounds, others from pumpers at waterside, and streams directed on tanks and condenser building to cool them down. As additional companies rolled in, streams were played on the blazing service building. fn the desperate effort to control the fire in the storage tanks, Chief Wandras sent a crew to the top of one of the adjoining 40-foot high storage tanks, with a 2 1/2-inch line fitted with a new type fog nozzle which delivers approximately 400 GPM of heavy water fog. This was the first time this type of nozzle had been used in actual fire operations by the Kearney firemen but it proved highly successful. According to Chief Wandras, the fires burning at the tank vents were snuffed out as if by magic. Water was continued until all danger of re-ignition was removed. The fire was under control by 2:00 A.M.

Four Investigations

Investigations into the fatal disaster were instituted immediately following the fire by the Kearney Fire and Police Departments, Hudson County Prosecutor’s Office and the State Labor Commission. Plant officials also cooperated in getting at the cause.

It was determined that the explosion occurred when the southwest breeze carried part of the vaporized contents of the 30,000-gallon tank of distillate down wind where it became ignited by a hot pipe or other spark. The first reports that the blast was caused by naphthalene were ii^orrect, it was stated. The initial explosion involved the service and condenser buildings and caused a flash back, which, in turn, ignited vapors at the vents of tanks 42 and 43. These containers did not explode as also was first reported.

Company fire brigade members assisted Kearney firemen in attacking the blaze and in shutting down pipe distribution systems in that area of the plant.

The property damage was tentatively established at $150,000.