BY THOMAS J. O’CONNELL

Serious vehicle fires in modern aboveground parking garages can present unique and difficult challenges to responding firefighters. Because of the infrequent nature of these events for individual officers and crews, a review of tactical considerations for these incidents can be helpful in ensuring a safe and effective outcome.

Modern aboveground parking garages are built with cost effectiveness in mind. They are typically no-frills structures that incorporate minimal fire protection features and maximize all available space including height (photo 1). Fortunately, most of these structures are constructed of cast-in-place concrete and precast concrete and present very little in the way of contributing to the fire load. Other garages use a steel frame, with or without spray-on fireproofing or encasement. Note: This article is restricted to “open air” garages and does not deal with enclosed aboveground parking garages and automated garages, which present their own unique problems.

RELATED FIREFIGHTER TRAINING

Motor Vehicle Accident in PA Parking Garage Provides Lessons for Firefighters

Humpday Hangout: Vehicle Fires in Parking Garages

|

| (1) A large multistoried open-air parking garage. Note vertical access issues posed by the trees. (Photos by author.) |

The aboveground garage is basically a stacked parking lot. Ceiling height is usually no greater than roughly eight feet. Each level usually consists of a perimeter wall (or cable railing) of about three to four feet in height. Each level is accessed by vehicle traffic using a ramp or a series of ramps. Pedestrian traffic accesses each level by stairwells and elevators. Ramps and sloped floors within the structure can have inclines as great as 15°. Rarely do the open-air parking garages have fire/smoke detection systems unless they are built underneath an occupied structure. Moreover, many of these structures only incorporate a Class I dry standpipe. Some of these structures may incorporate sprinkler systems.

FIRE SCENARIOS

The typical serious vehicle fire scenario on any level presents some challenges. Typically, the vehicle is sandwiched between at least two other vehicles and as many as three additional exposures if the vehicles are parked nose to nose. The low ceiling height prevents the venting of heat and actually re-radiates it back down onto the vehicle and adjacent vehicles. The low ceiling height prevents rapid release of smoke and permits smoke to quickly bank down into our operating zone. The trapped smoke, in some cases, can make locating the burning vehicle difficult and set the stage for a very dangerous situation when civilians attempt to exit the structure by driving through the smoke with their personal vehicles, thereby placing firefighters at risk of being struck by a moving car within the garage.

Stretching the initial attack line can also be a challenge. One method for accomplishing this is to pull a preconnected 1¾-inch line and hoist it to the level of the fire. More often than not, this method cannot be used because of the length of the stretch. Keep in mind that some of these aboveground parking garages have a footprint area of 350,000 to 600,000 square feet or more.

A second method involves using high-rise or hotel packs from existing standpipes if they are present. More often than not, the standpipe systems are dry systems that have been compromised by civilians in the way of missing caps and opened valves. On more than one occasion, firefighters using these systems have found themselves unable to produce a proper fire stream and do not have the personnel or time to examine every standpipe outlet on every level. This is the reason local fire prevention personnel must be vigilant in keeping a close eye on maintenance on these systems, requiring periodic inspections to verify system code compliance, including proper valve operation, piping integrity, fire department connection operation, and removal of debris and trash from the system. Of course, as a dry system, expect a delay in getting water to the nozzle as air is bled from the system.

This leads to another method of attack. The engine company crew attempts to guesstimate the location of the vehicle fire. The officer and crew proceed to the level of the fire with high-rise kits or hotel packs along with a utility rope. They then hoist a 2½- or three-inch supply line to the level of the fire and advance it in proximity of the burning vehicle at which time they attach the high-rise kit or hotel pack to the supply line and advance it on the burning vehicle.

There are remaining challenges with this method: If the hoseline is stretched across an interior ramp or traffic way, there’s a risk that the hose will be run over by civilian vehicles operating within the building; some types of aboveground parking garages include ramps that transverse the core of the building for almost the entire length. This type of construction places physical barriers such as railing, grating, sloped roadways, and fences between the supply line being advanced and the fire area (photo 2). For this reason, it is necessary to preplan all of these facilities and for first-arriving crews to conduct a thorough and rapid reconnaissance prior to stretching the initial attack lines.

|

| (2) These sloped roadways and parking slots are deep inside the structure. Note the physical barriers that will slow hoseline advancement. This type of design can permit running fuel to drop down to the lower levels or the fire to autoextend to the upper levels. |

FOAM OPERATIONS

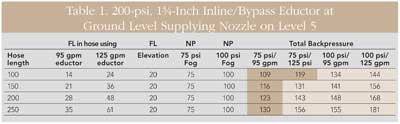

This type of incident, involving vehicles and fuels, necessitates that you consider using firefighting foam on upper levels. Apparatus that use around-the-pump proportioners and foam injection systems should operate without being impeded when delivering foam to heights typically found in these elevated structures. Bypass and inline foam eductors, either mounted on the apparatus or portable units operated at street level, can fail to deliver foam to upper levels of these parking garages because of the backpressure placed on the eductor as a result of the friction loss incurred from excessive elevation. This can quickly lead to a lot of chaos on the fireground. One pump operator’s manual explains that the pressure at the outlet of portable or inline eductors (also pulled backpressure) must not exceed 65 to 70 percent of the educator inlet pressure. Most inline or bypass eductors operate at a pressure of 200 pounds per square inch (psi); 65 percent of this is 130 psi. The manual also states that the eductor backpressure is determined by the sum of the nozzle pressure, friction loss in the hose between the eductor and the nozzle, and the elevation pressure. If backpressure is excessive, no foam concentrate is inducted into the water stream.

Table 1 shows that using an inline or a bypass eductor at street level with the eductor near the pump panel and attempting to place foam on the fifth floor of a parking garage may not be possible using the equipment shown in the table’s shaded areas. For example, a 100-psi fog nozzle may fail to produce foam through a 100-foot hose that has been attached to the discharge side of a 95-gallon-per-minute eductor. There is simply too much backpressure.

| Table 1. 200-psi, 1¾-Inch Inline/Bypass Eductor at Ground Level Supplying Nozzle on Level 5 |

|

There are several methods for overcoming backpressure and its negative effects on foam production at elevated levels.

- Mix the foam in a batch: Pour the foam concentrate directly into the foam tank at proper ratios to create one big batch of booster tank foam. As an example, pour 22½ (25 rounded) gallons of three percent aqueous film-forming foam (AFFF) or 7½ gallons of one percent AFFF concentrate into a 750-gallon booster tank.

- Bring the foam and the eductor to the level of the fire. Remember, the backpressure affecting the eductor is the pressure from the outlet of the eductor to the nozzle. Take away elevation pressure and some of the friction loss in the hose, and you are back in a normal operating range.

- Use a combination of low-pressure fog nozzles and larger-diameter hose in portions of the hoselay, such as 2½- or three-inch up to the last 100 feet where it is reduced to a 1¾-inch line.

SAFETY AND TACTICAL CONSIDERATIONS

When operating at vehicle fires inside aboveground parking garages, you may want to consider the following:

- Immediately secure the area to eliminate civilian pedestrians and vehicular traffic. This is particularly important to ensure that firefighters are not struck by vehicles and hoselines are not damaged. Secure all ramps upstream and downstream of the incident.

- It is quite common for fuel to leak from burning vehicles. Anticipate the spread of leaking fuel, especially when the burning vehicles are on a sloped floor. Other structures of this type incorporate floor drains that can transport burning fuels to remote locations. This may necessitate assigning an entire company to monitor and deal with this aspect of the incident.

- Although the structure most often has an open-air design, the tremendous volumes of smoke generated by vehicle fires coupled with the low ceiling height, and possibly sprinkler heads creating “cool smoke,” dictate the need for the initial attack crew and subsequent crews to bring thermal imaging cameras with them. They will help the crew that encounters a wall of thick smoke to not only rapidly locate the fire but also to observe vehicles and people on the other side of the incident, running fuel fires, ceiling conditions, floor drains, and possibly standpipe connections.

- The close proximity of a heavily involved vehicle to the edge of an interior ramp combined with low ceiling height may allow for fire to lap or autoextend to a vehicle on the level above the burning vehicle much like fires autoextend vertically by windows on a normal building (photo 2). This necessitates assigning a crew to check areas above the fire level.

- Delays in discovering and reporting the vehicle fire to the fire department; low ceiling heat confinement; and the time required to hoist hoselines, locate the fire, and traverse to the fire location can easily result in several vehicles becoming well involved by the time the initial attack crew reaches the fire location. This will most likely require a sustained water supply to the attack engine and possibly additional lines.

- The assignment of two or more engines to stretch lines and attack the fire, a crew to assess vertical extension, personnel to secure vehicular traffic flow, and crews to address possible running fuel fires clearly demonstrates that a crew of four to five firefighters (regardless of how many units they respond on) may be woefully insufficient to efficiently and safely conduct operations. Consider assigning an upgraded response or even a structural response to vehicle fires inside these structures. Company officers arriving at a dispatched “car fire” and discovering that the vehicle is inside such a building should not hesitate to upgrade the assignment. You can always cancel responding units later if you don’t need them.

Serious vehicle fires in modern aboveground parking garages are not very technically challenging to well-trained crews and officers. They do, however, often require a significant increase in responding firefighters and an increased situational awareness of the unique and uncommon problems presented.

THOMAS J. O’CONNELL, EFO, MPA, is a 34-year career firefighter with the Broward County (FL) Sheriff’s Office Department of Fire Rescue and division chief of training. He is a Florida instructor III and a technical rescue and hazardous materials technician.

More Fire Engineering Issue Articles

Fire Engineering Archives