Rekindle

An Old Problem with a New Twist

CONSTRUCTION

Have you ever had one of those days when things seem to start out too good to be true and end with everyone wondering what can go wrong next? Let me tell you about the shift that Murphy’s Law worked on before time in its infinite mercy blurs the details.

It was the first shift of the new month and the first day of new station assignments, a newly promoted driver engineer (chauffeur), a newly promoted lieutenant, and three newly appointed rookies.

The captain whom I was relieving gave me the good news/bad news routine. I took the bad news first, my dispatcher had called in sick. Because of re-assignments, the only person besides myself trained to operate the computer aided dispatch was a paramedic who was working his first shift as a fire lieutenant. The good news was that I had plenty of manpower. A neighboring station house was temporarily uninhabitable, so the men and equipment were to run out of my station for a few days. Also, it was a Saturday, so there would be no top brass around to come up with extra demands. Prevention, education, and training were all closed for the weekend.

First things first. I assigned my paperwork to the lieutenant, telling him to think of it as on-the-job training, and I trained my sharpest firefighter on the computer.

By 9:30 A M., our stand-in dispatcher was doing a fair job, the new lieutenant had a good start on the forms, all the apparatus had been checked, and the janitorial duties were completed. It was time for a coffee break and to get acquainted with the rookies. I assigned each rookie to an experienced firefighter to ease their transition and acceptance into a new job, and to motivate the seasoned firefighter with a sense of importance and pride (his man would be the best damn rookie since he was one).

Shortly after 10 A M., we received a telephone alarm. The caller was a calm woman who told us that her air conditioner had spit out a few sparks and was smoking. Although this would normally call for a response of one engine and one paramedic rescue unit, I felt that this would be an excellent training and evaluation opportunity; a chance to mold individuals into a team that would work together for the next six months. Therefore, we paged out “structure fire, all units in the station respond,” and the dispatcher asked the lady if she knew where the circuit breakers were, how to turn them off, if she could get to them without going near the air conditioner unit, and, if so, to turn them off and wait outside for us to arrive.

Two pumpers and two rescue rigs with 16 men entered the block of two-story attached townhouses. A woman was pointing to her house and no smoke was showing. This was textbook perfect; a hydrant located 500 feet in front of the house, a group that had not as yet worked together, and a call that seemed minor. This would make an excellent training exercise.

I radioed to the pumpers to set up a staging area at the hydrant and to prepare to execute a straight lay. The rescue trucks were ordered to park past the house and don self-contained breathing apparatus (SCBA) in preparation for search and ventilation.

The woman was still calm as we walked to the front door. She told me that she had turned all the electric off and that the air conditioner was in the first closet on the right at the top of the stairs.

Closet?

Upstairs?

Central air conditioning?

Duct work?

Ooohh damn!

Run to the stairs. Thick black smoke. Can’t even see the top steps. Hear crackling of flames. Order the supply line layed. Call fora l 3/4-inch handline. Send two firefighters with a 35-foot extension ladder to the rear yard to vent the second floor windows. Two more men vent the front windows. Order a rookie to get me an SCBA.

The fire never had a chance. We worked like a well-oiled machine. What a stop! The lieutenant led his men to the seat of the fire before opening the line. They used less than 100 gallons of water; the steam did the rest. We never did need to charge the supply line. The air conditioner closet was a burnout. There was surface fire in the hallway, minor fire extension into the attic around the ducts, and smoke damage throughout the second floor.

A fire investigator was ordered to report to the scene, and men and apparatus were put back into service. One engine and the rookies were held at the scene to overhaul. The l 3/4-inch line was backed out and a booster line was brought in to minimize water damage in overhauling. Smoke ejectors were set up, inspection holes were put in the top of the walls, and the ceiling of the air conditioner closet was pulled. The rookies were instructed in the “back to unburnt wood” concept of overhauling.

Isn’t it great when everything comes together like it’s supposed to?

To complete overhauling, we needed access into the attic. The access hatch was in the ceiling of the closet of the master bedroom, about 25 feet from the air conditioner closet. The roof had a 6foot high peak and was supported by 2 X 4 wood trusses on 24-inch centers. (No snow load problem in Florida.)

To get from the hatch to above the air conditioner closet, we had to feel our way through 6to 8inch deep, blown insulation covering the bottom cord of the trusses. Being careful to step or kneel only on wood, we made our way to the area of vertical extension. A truss and some 2X4 framing had some surface burn near the duct penetration. We wet down and removed the insulation around the burned area, checked for sparks and embers, and then wet the surface of the general area. The investigator accepted custody of the scene, and all units returned to quarters by 1 P.M.

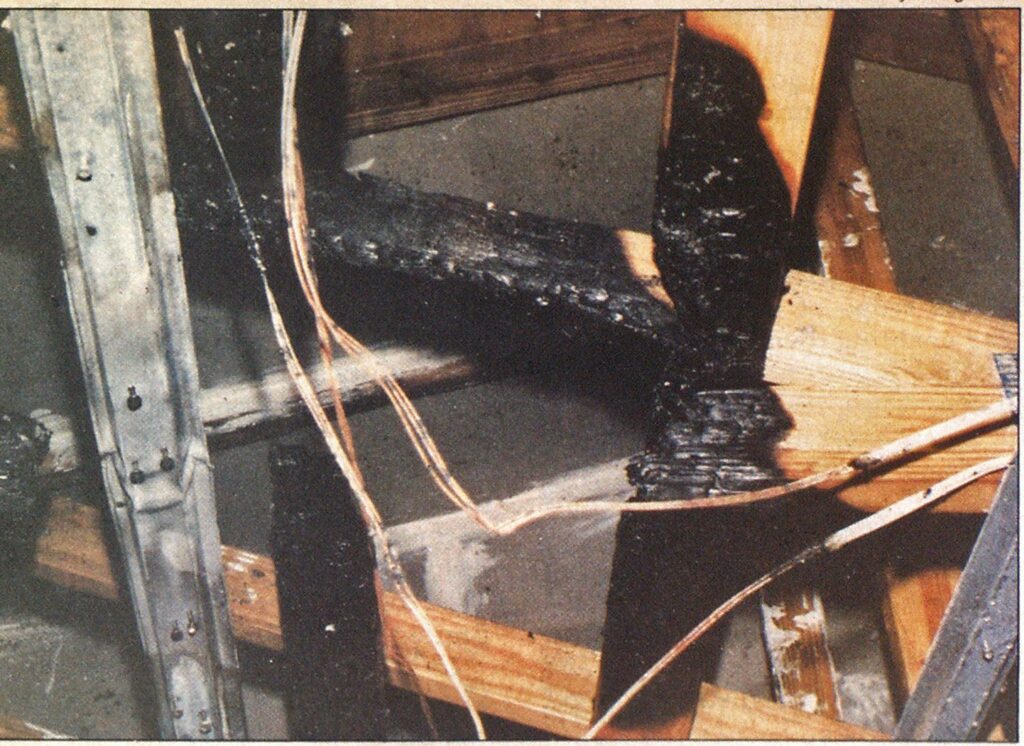

At 4:30 P.M., the owners of the house called us to report some light smoke in the attic. We responded and found a wood truss burning about four feet away from the previous fire with no apparent connecting path. The bottom cord of the truss had burnt through, leaving a gap of six inches. The stubs of the 2X4 were completely carbonized with deep alligatoring.

Photos by Geofoe Odell

We pulled the ceiling for more than two feet in all directions, way into clean wood, and then soaked the entire attic, trusses, sheathing, and insulation. The investigator returned to the scene to verify that there was no connecting path. I told the owner that we would check back later.

At 8 P.M., we returned to the house to check for heat and/or smoke. There was neither.

At 1:15 A.M., we received a call from the same location. Smoke was coming out of the eaves.

Upon arrival, we found another truss burning about five feet from the most recent fire. While waiting for the line to be charged, I pulled down more Sheetrock from the ceiling near the burn site. It exposed a burn pattern in the insulation. The burn pattern was cone shaped with the classic triangle spreading down from the surface of the insulation and out to where it had ignited the truss. We took a sample of the insulation for testing and overhauled again.

LESSONS LEARNED

Our Fire Investigation Division Usted the insulation and reconstructed the attic conditions. The insulation in this home was a finely shredded, treated newspaper that burns only while heat is being applied. When the heat is removed, the fire goes out. If a spark or ember drops into the insulation, smoldering starts. The insulation prevents the heat from dissipating, and the smoldering spreads vertically as well as horizontally. Wetting the surface stops the surface spread only. When the smoldering reaches wood, it causes pyrolytic decomposition, lowering the ignition temperature of the wood. This insulation, which inoffensively occupies our attics and is reportedly legal, provides, in effect, thousands of square feet of fuse with an undetermined delay time. An additional factor to consider is the roof’s integrity; two adjacent trusses had their bottom cord burn through.

Shredded paper insulation is widespread in our area, and chances are it exists in your district as well. Will you recognize the problem if faced with a similar incident?

Would an infrared heat detector have spotted the ember through the insulation? Would a wet water type additive have allowed the water to reach and cool the ember? I don’t know, and, in any case, they were not available to us at the time.

This incident was just another one of the many lessons that life and the fire service hold out to us. And by sharing our experiences with each other, perhaps we can increase our knowledge and awareness and decrease our mistakes. After all, a mistake is nothing more than an already learned negative lesson repeated a second time.