By Trey Young

Rapid intervention, the act of mitigating life-threatening emergencies and removing compromised firefighters from an immediately dangerous to life or health (IDLH) environment, is the most impactful mission we could be assigned. How we perform cannot be left to chance. Not only do lives hang in the balance, but our performance on one of the worst days of our careers will affect our lives, our family’s lives, the lives of other families, and our fire department forevermore. The Asheville (NC) Fire Department (AFD) learned this lesson in the most painful way on July 28, 2011.

The Event

The trajectory of the AFD dramatically changed on July 28, 2011, when our department lost Captain Jeffrey S. Bowen of Rescue Company 3 during a firefight in a high-rise medical office building. Assigned search, Bowen led a crew of five to operate on the fire floor. While working on the fire floor, deep into a very cut-up floor plan, he and other members of his company began to run low on air. As their low-air alarms began to chime, they slowly began to exit the structure. When they finally reached the north stairwell, two members headed down. Then, for reasons we will never know, Bowen left the area of the stairwell, disappeared back into the smoke, and headed toward the fire room. The two remaining members of the crew immediately pursued him, but he was moving with a purpose. Before long, the now crew of three found themselves back in an office alcove adjacent to the fire room, an area they had just searched before beginning their exit.

RELATED FIREFIGHTER TRAINING

First-Due Battalion Chief: The Rapid Intervention Team

Essential Hoseline Management for the Rapid Intervention Team

Rapid Intervention Teams: Saving Their Own

Rapid Intervention Team Size-up and Actions

At this point, on arriving and presumably not finding what he expected, Bowen seemed to lose his drive, his motivation. The two crew members with him noticed this shift in countenance and seized control of the situation. They put Bowen between them to lead him to an exit; however, even though they had been there before, they were still disoriented.

The firefighter in the rear saw the other firefighter and Bowen disappear into the thick smoke around the same time his low-air alarm quit banging (a telltale sign that he would soon be out of air). At that moment, he felt water from the attack line hit him in the back. Nearly out of air and with no sign of the two members he was following, he turned and headed toward the stream of water. He located the attack crew and, out of air, was removed to the bucket of an aerial platform.

Bowen and his firefighter, now a team of two, moved through the heavy smoke and moderate heat, desperately trying to find the stairwell. Bowen ran out of air. This was the first time in this cascade of circumstances that he attempted to call a Mayday. He remained standing, removed his regulator, and initiated the Mayday call.

He ordered his firefighter to “buddy breathe.” But since Bowen was completely out of air, he didn’t have the audio cue of free flowing air to engage his air-saver switch when he disconnected his regulator. His firefighter dropped to his knees and hooked up their emergency breathing support system (buddy breather hoses) while Bowen completed the Mayday transmission. In another cruel twist, as the buddy breathing connection was made, all the remaining air from the firefighter’s self-contained breathing apparatus (SCBA) exited through Bowen’s dangling regulator because Bowen had not engaged his air-saver switch. Now, they were both completely out of air!

Bowen, having vomited in his mask, was now on the floor, still responsive but no longer “in the fight.” His firefighter took off with only a flathead ax to locate the exit. He came across the south stairwell. It was clear from smoke and previously untouched, so it had not been subjected to the reverse stack effect experienced in the north stairwell. Marking the exit with his hand tool, the firefighter returned to Bowen and dragged him to the clear south stairwell and down to the third floor. The firefighter then passed out. Another group of firefighters located them, unresponsive, and removed them from the structure. Bowen was pronounced dead at the hospital. His firefighter made a complete recovery.

The Rapid Intervention Team—Then

Undoubtedly, you are thinking, “Where was the rapid intervention team (RIT)? A RIT was assigned to the fireground that day, and we had a rapid intervention standard operating guideline. The RIT was deployed after the Mayday was called.

You see, on July 28, 2011, the AFD was not as prepared for rapid intervention as we should have been. Although rapid intervention was just one link in a long chain of events and issues that led to Bowen’s death, the AFD has taken great strides to remedy those issues and ensure that our firegrounds will be more survivable. The AFD recognized gaps and aggressively worked to fill them. We developed a training plan and a deployment model and conducted a live fire analysis, all of which are discussed below.

On July 28, 2011, rapid intervention in the AFD was viewed more as a checking of the box instead of a life-saving priority. The company assigned as the RIT was not properly trained, properly staffed, or properly equipped.

The RIT headed up the north stairwell, the attack stairwell, which was charged with smoke because of atmospheric conditions. Because of abnormally warm temperatures outside and the air-conditioning inside the building, crews encountered a reverse stack effect in the north stairwell. The RIT had to climb six stories to the fire floor while breathing air. They made it to the fire floor, advised command that they could hear PASS devices going away from them, and then announced that they did not have enough air to pursue. They then exited the building.

The AFD firefighters who located the two missing firefighters in the south stairwell on that fateful day were not assigned to the RIT; they were just trying to make something good happen.

The lessons we learned that day were hard, painful, and figuratively and literally expensive. Since then, the AFD adopted the goal of sharing these lessons and ensuring that Bowen’s sacrifice will be honored by preventing another agency from repeating our mistakes.

Staffing and Training Changes

That incident changed the way the department operates in many meaningful ways. During the internal postincident analysis (PIA) of the July 28, 2011, fire, the AFD created 17 focus groups to assess the department’s operations and make recommendations in their respective areas. The Rapid Intervention, Mayday, and Air Management groups focused on the RIT program.

The PIA Committee determined that the assignment of a RIT had been untimely, the team was understaffed and inadequately equipped, and the members were not adequately trained. As a stopgap measure, we automatically assigned the third-due engine to RIT. This was an improvement; however. untrained, understaffed, and underequipped companies were still charged with RIT responsibilities.

The RIT PIA Committee made the following recommendation: “The AFD will be best served by three designated RIT trucks that are highly trained, well-staffed, and properly equipped. The practice of leaving RIT responsibilities unknown has created a culture of avoidance and complacency. We believe that a responsibility given to everyone is owned by no one.”

In May 2014, three engine companies (one in each battalion) were staffed with four personnel, equipped, and appropriately trained. One RIT company trained to the technician level would be adequately deployed on all reported structure fires. On confirmation of a working fire, to further bolster RIT response, two additional engines and one additional ladder trained to the operations level would be deployed.

All AFD firefighters were to train to the operations level by completing the North Carolina Rapid Intervention Crew Certification (National Fire Protection Association 1407, Standard for Training Fire Service Rapid Intervention Crews). To gain/retain assignment on a RIT company, team members also have to complete North Carolina Breathing Equipment and Firefighter Survival School technician-level training, North Carolina Thermal Imaging School, and North Carolina Technical Rescuer certifications.

The RIT—Today: The Study Design

After the completion of training, the purchase of equipment, and the staffing of the teams, we tested the plan. The evaluation consisted of a hands-on, live fire analysis using a complex RIT scenario to ensure the credibility of the RIT deployment model and to determine the time, personnel, and breathing air requirements of such an incident. The AFD sought to analyze our ability to mitigate a complex RIT incident and to ensure that we were providing the most survivable fireground possible.

Core Requirements

The analysis staff designed a scenario that met the following core requirements.

Live Fire Training. Live fire is essential to a realistic training environment. Since RIT deployments are physically and psychologically stressful, it is important to build as much stress into the scenario as possible. External stress was applied through the use of heat and smoke.

Team-Oriented Scenario. The scenario incorporated some elements of the “Pittsburgh Drill” because the drill necessitates a high degree of teamwork for successful completion. We wanted to test both individual and team skills.

Labor Intensive. A hard work requirement adds additional stress (internal and external) that helps to replicate the stress encountered in an actual deployment and provides a sufficient distribution of labor to thoroughly test the AFD’s multicompany “RIT Group” deployment model.

Sample Size

To ensure that credible and useful data was produced, we needed a large sample size. The analysis was carried out over 12 evolutions consisting of one RIT company, three RIT group companies, one battalion chief, and one safety and training officer each. All 16 AFD companies across all three shifts participated. This resulted in an overall participation of 48 fire companies, 12 battalion chiefs, and 12 safety and training officers—196 active participants trained for a combined 588 hours and created more than 3,100 data points.

Analysis of Five Critical Tasks

At its core, rapid intervention can be boiled down to five critical tasks involving the compromised firefighter: locate, extricate (if entangled or entrapped), provide air, package, and remove.

Locate

The first critical task measured was locating the down firefighter. Quickly locating the firefighter helps to ensure his survivability. When a firefighter declares a Mayday, the clock starts ticking. However, a RIT must be concerned not only with the ticking minutes and seconds but also, except in cases of major trauma or hostile fire conditions, with the down firefighter’s air gauge. If you can keep the firefighter on air, you have time to effect a rescue. In the critical task of locating the firefighter, the RIT does the following:

- Connects a search rope to a hard point on the exterior near the point of entry.

- Enters the structure performing a targeted search based on intelligence gathered from all available sources.

- Advises the RIT leader (RITL) (who advises command) that the down firefighter has been located and of his precise location.

- Tightly secures the search rope to a hard point near the location of the down firefighter.

The time it takes to locate a down firefighter will vary according to factors such as the following: LUNAR—Location, Unit, Name, Air/Assignment, Resources; travel distance; building topography; obstacles; and RIT training. An accurate LUNAR report increases the down firefighter’s survivability: The more specific the location given, the more targeted the RIT can be in its search. A RIT that has trained and searched together regularly can dramatically affect location time through targeted search efficiency.

The average locate time from the time of the Mayday was 8 minutes, 25 seconds (08:25); from RIT deployment, 07:55; and from RIT entry to location, 06:43. Disparities in locate time were attributed to the time it took the initial RIT to enter the structure from the time of the Mayday.

Note: RIT response times can be reduced by the degree of preparedness of the RIT members, who must be mentally and physically prepared, and by preplanning and rehearsing the immediate steps the RIT will take after the Mayday is sounded. To help ensure this, the AFD recruit school includes the Resilient Mind program, developed by AFD Firefighter Jay Bettencourt and Dr. Scott McGregor. This entry-level mindfulness program teaches mental management during stressful conditions. AFD firefighters are also taught the Combat Mindset, developed by Lt. Col. Jeff Cooper and used by the United States Marine Corps infantry. AFD firefighters are required to participate in at least one hour of physical fitness per shift. In addition, the RIT must have all of its equipment easily accessible and well-organized for rapid deployment and must have personal protective equipment (PPE) in a state of readiness. Full PPE, with the exception of the SCBA mask, should be donned at all times during standby.

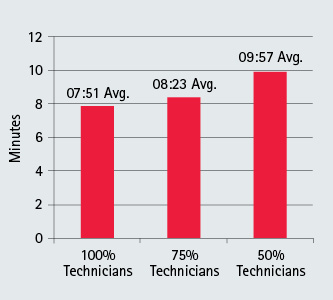

Companies in which 100% of the members were certified to the RIT technician level were most efficient (Figure 1). The analysis showed that it takes one RIT consisting of four firefighters to locate a compromised firefighter.

Relative to air consumption, at the time of the study, the AFD used several models of 4,500 pounds per square inch (psi) SCBAs equipped with 30-minute cylinders, heads-up displays, integrated PASS, an emergency breathing support system (EBSS), and the universal air connection (UAC).

Figure 1. Locate Time Relative to Company Training Level

Figures by author.

The average entry air pressure of the RIT companies across all evolutions was 4,310 psi. The average air pressure of the RIT company on locating the down firefighter was 2,594 psi; RIT companies consumed an average of 1,716 psi up to the point of locate, for an air consumption rate (ACR) of 255.47 psi per minute while performing a targeted search.

Extricate

This critical task is made up of the following elements:

- The RITL advises command that the firefighter is trapped and requests further resources as required. For this analysis, the down firefighter was trapped beneath various wooden debris, with a combined weight of 580 pounds.

- RIT extricates the compromised firefighter from any entanglement or entrapment.

- The RITL notifies command that the firefighter is freed.

The nature of the entrapment required several RIT members to work together to move multiple heavy wooden objects from the down firefighter. The heaviest item weighed approximately 265 pounds. These objects were placed to simulate construction debris that had landed on the firefighter during a partial structural collapse. The RIT companies had at their disposal heavy lifting and moving equipment such as high-pressure lifting bags, cribbing, hydraulics, and prying tools; but every company decided to extricate the trapped firefighter by hand. Obviously, the complexity of the entrapment will determine the required equipment, personnel, and rescue complexity, which will directly affect extrication times.

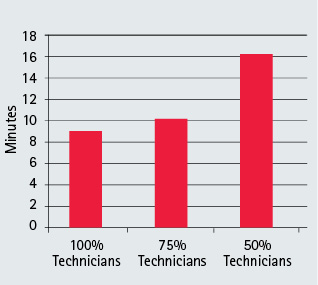

Figure 2. Extrication Time Relative to Company Training Level

The average extrication time from the time of the Mayday was 10:41; from RIT deployment, 10:12; from RIT entry, 08:59; and from RIT locate, 02:16. As we found with locate times, technician-level training was a factor in extrication times (Figure 2). This study demonstrated that for efficient performance, technician-level training and having a RIT company properly staffed on any given day were needed.

One four-member RIT company accomplished extrication in every scenario but one. In that case, the down firefighter was partially extricated. Two four-person RITs were needed for complete extrication. On average, it took one four-member RIT company to extricate a down firefighter.

The average air pressure of the RIT company on extrication of the down firefighter was 1,956 psi; RIT companies consumed an average of 2,354 psi while searching for the firefighter up to the point of extrication. This represents a cumulative ACR of 262.05 psi per minute. The average consumption for the same period was 443 psi, for an ACR of 214.19 psi per minute.

Provide Air

Providing supplemental breathing air to the down firefighter consists of the following elements:

- The assigned “Air Firefighter” (AF) triages the down firefighter’s SCBA system to determine the proper air connection (high pressure/low pressure).

- The assigned AF connects the RIT pack to the connection of his choosing.

- If a low-pressure connection is used, the RIT pack is connected to the down firefighter’s waist strap.

- The RITL notifies command that a positive air supply has been established.

The results of the AF’s SCBA triage is the primary factor in determining when to provide supplemental breathing air to the down firefighter. For this analysis, the down firefighter’s SCBA system was completely intact and functional with all connections available. Assuming that there is no structural failure of the SCBA (the mask, hose, regulator, or cylinder, for example), providing air through the EBSS or the UAC is relatively quick. The EBSS connection (low pressure) is instantaneous; however, it is permanent, meaning that the RIT pack must travel with the compromised firefighter, within the length of the RIT pack’s low-pressure hose, for the duration of the connection. It is critical that the AF properly assess the compromised firefighter’s SCBA. Just because the UAC is quick does not mean it is always the best option. If you rush to hook up the UAC without assessing and realize that the down firefighter has pulled his regulator, you have done nothing at all to improve his survivability.

The UAC connection (high pressure) is complete in less than 60 seconds, even if the down firefighter is completely out of air. In cases of failure (mask, hose, regulator, cylinder), more complex operations such as regulator or mask swaps may be needed. These methods are more complex, time consuming, and hazardous.

The first four options for providing a down firefighter air (UAC, EBSS, regulator disconnect coupling, and regulator swap) are single-person jobs. Only the complete mask swap necessitates two personnel. The skill is inherently complicated by the addition of a second set of hands, so it must be drilled on regularly. Additionally, this skill also highlights the importance of crew integrity and staffing RITs with properly trained firefighters.

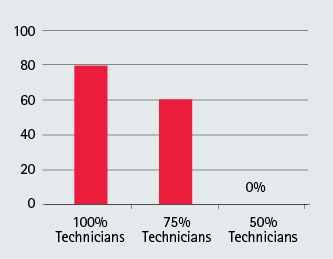

Training affects the time needed to supply supplemental air (Figure 3). Training issues manifest themselves in various forms for this critical task. It is recommended that an AF be assigned; assignment breeds a sense of ownership, which is valuable for mission accomplishment. The AF must be intimately familiar with his RIT pack to the point that fire gloves, low visibility, and high stress are not encumbrances to his performance. The AF must also be familiar with the RIT connections available to him in his department’s SCBA inventory. Some SCBAs have five RIT connections (UAC, EBSS, regulator hose, regulator, mask). Every department may not have SCBAs equipped with all five connections. The AF must know what connections are available. If he cannot know in advance because of a lack of standardization, he can check for available connections during the triage.

Figure 3. Air Time Relative to Company Training Level

Training manifests itself also in performance and, therefore. the time it takes to provide air, the number of repetitions. It takes 200 repetitions of a given task to develop automaticity (paraphrased from Christopher Brennan’s “How to Avoid Training Scars”). The repetitions can be performed anywhere at any time. Without high repetitions, an AF cannot expect to reduce supplementation time.

Throughout the analysis, the average air time from the time of the Mayday was 10:37; from RIT deployment, 10:07; from RIT entry, 08:55; from RIT locating, 02:11; and 00:36 after extrication.

Throughout every evolution, the initial RIT was able to provide supplemental air to the down firefighter. It took one four-member RIT to provide air to a down firefighter. The average air pressure of the RIT company on providing supplemental air to the down firefighter was 2,108 psi. RIT companies consumed an average of 2,202 psi, resulting in a cumulative ACR of 246.94 psi per minute. The average air consumption while performing the task of air (from the time of extrication until air complete) was 247 psi. This resulted in an ACR of 357.01 psi per minute. This increase in ACR is likely attributable to the strenuous nature of the extrication.

The initial air connection, although important, is not the end of the AF’s job. He must continuously manage the down firefighter’s air and the integrity of his SCBA system. We found that the primary cause of loss of air by the down firefighter was the dislodging of his mask and the subsequent low-pressure leak. Regularly checking every element of the compromised firefighter’s SCBA will significantly increase survivability.

If the RIT had to leave the down firefighter, air management at that time affected firefighter viability. The RIT must hook the RIT pack into the low-pressure side of the down firefighter’s SCBA; this will ensure that the firefighter will have as much breathing air as possible. Throughout the study, several RITs “bumped” the down firefighter’s UAC connection prior to leaving, causing low-pressure leaks that left the down firefighter out of air before the next RIT team arrived. It is imperative that the next arriving RIT’s AF triage the down firefighter’s air system to determine his air status and what connection is needed and was used by the previous RIT. Passing down this information from one RIT to the next is vital in ensuring the down firefighter’s viability.

Package

Packaging, the act of converting the down firefighter’s SCBA into a drag harness, is incredibly important for effectively and efficiently removing the down firefighter. I was a proponent of packaging before conducting this study; but, if you had told me that packaging was a matter of life and death, a skill that affects a compromised down firefighter’s survivability, I am not sure I would have believed it. This study confirmed it. The package critical task is made up of the following elements:

- The “Package Firefighter” (PF) of the RIT converts the compromised firefighter’s SCBA into a drag harness by disconnecting the waist strap and reconnecting it between the compromised firefighter’s legs.

- If a low-pressure air connection is used, the RIT pack is then connected to the down firefighter’s converted waist strap.

- The RITL notifies command that the down firefighter is packaged for extract.

Packaging should take only seconds. Using the SCBA waist strap conversion accomplishes several things: The SCBA is converted into a drag harness with two large handles (the shoulder straps); it locks all the firefighter’s PPE in place except his boots, helmet, and mask; it does not increase the firefighter’s profile and makes the low-pressure RIT pack connection easier to manage; and it does not ask a firefighter to tie harnesses with webbing or remember which color loop goes on the leg during physiologically stressful conditions.

Packaging must be a single-person job. Multiple firefighters attempting to package the down firefighter is problematic, especially in low-visibility situations. As with all other tasks, the PF should be assigned and have had much practice well before the incident. Packaging may take place during or after the air task is completed. The AF always has the “right-of-way” to the down firefighter. With that understanding, if it is possible to package while the AF is working, that will decrease time; however, air supply should under no circumstance be delayed to complete packaging first. In only 8% of the evolutions was packaging completed prior to air.

The packaging times during this analysis varied greatly for several reasons. In some instances, the down firefighter was never packaged; other times, the initial RIT company packaged the firefighter, and sometimes companies from the RIT group completed packaging. During 58% of the evolutions, the RIT company packaged the down firefighter; in 25% of the evolutions, a RIT group company packaged the down firefighter; and in 17% of the evolutions, the down firefighter was never packaged.

Throughout the analysis, the average package time from the time of the Mayday was 16:11; from RIT deployment, 14:32; from RIT entry, 13:21; from RIT locating, 07:34; 06:10 after extrication; and 06:20 after air.

The primary way to reduce packaging time is to ensure it is a priority for the initial RIT company. The high average packaging times are further representative of training issues. Every RIT company located, extricated (at least partially), and provided air to the down firefighter; however, every RIT company did not package the firefighter. Figure 4 again demonstrates that advanced training and proper staffing of RIT companies are paramount for efficient mission accomplishment.

Figure 4. Percentage of Evolutions in Which the Initial RIT Company Packaged Relative to Company Training Level

In 30% of evolutions in which the down firefighter was packaged, companies used an alternate packaging method such as a “Mega Mover” or a webbing sling. The webbing sling was successfully used once. The Mega Mover did not work both times it was attempted. SCBA waist strap conversion is the only technique that was consistently successful. Success is defined as the down firefighter being removed from the structure with the packaging system and all PPE still intact.

Packaging is a single-company task. However, in 42% of the analyzed evolutions, the initial RIT did not package. This issue can be corrected through training. In 58% of the evolutions, the initial RIT (four personnel) packaged. Based on this, on average, it takes six personnel (1.5 RITs) to package; with proper training, that number can easily be decreased to four firefighters.

The viability of the down firefighter is directly affected by packaging. The act of converting an SCBA is not a life-and-death task, but it is indicative of a well-prepared RIT. When the compromised firefighter is properly packaged, the likelihood of PPE removal or air supply loss is greatly reduced. Packaging also makes transporting the down firefighter easier and more efficient, especially when moving up, down, over, and under obstacles and building topography. In each evolution where the down firefighter was not packaged (17%), he was not viable when removed. In two evolutions, packaging was completed, but the firefighter was not viable. In the first instance, a subsequent company disconnected the SCBA conversion prior to removal. In the second case, packaging did not take place until the 51st minute, and the down firefighter ran out of air before packaging.

Remove

Removal of the compromised firefighter is made up of the following elements:

- The compromised firefighter is removed from the IDLH by the nearest feasible point of egress.

- The RITL notifies command that the down firefighter has been removed and the advised location of removal.

Removal is labor intensive and time consuming. Removal times, like locate times, are directly affected by travel distance, obstacles, and building topography; they can be affected also by training, staffing, and physical fitness of team members. Removal times can be reduced by using the nearest egress. This was not an option during the analysis because the staff wanted to create a scenario that was labor- and personnel-intensive. The RIT inside the structure or personnel outside can determine the nearest feasible point of egress. As the RITL communicates locations and progress, command/exterior crews may be able to direct, secure, or create a nearer point of egress.

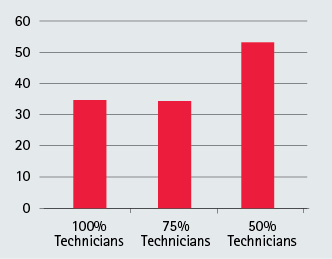

The average removal time from the time of the Mayday was 37:40; from RIT deployment, 37:10; from RIT entry, 35:58; from RIT locating, 30:05; 26:58 after extrication; 27:03 after air; and 19:56 after packaging. The importance of technician-level training and proper staffing of RIT companies was again evident in removal times (Figure 5).

The entire RIT group (four companies) has a hand in the removal time. However, the statistics gathered during this analysis clearly and repeatedly demonstrate that the quote from the late Lt. Andrew Fredericks, Fire Department of New York, could easily be paraphrased to apply here: “As the first RIT goes, so goes the operation.”

Figure 5. Removal Time Relative to Company Training Level

The analysis revealed that, on average, a minimum of 15 firefighters (four RITs) are needed to remove the down firefighter. The AFD RIT Deployment Model of one RIT company and three RIT group companies (an additional two engines and one ladder) completed the evolution with one deployment into the structure only 16% of the time. Even with the relatively heavy RIT staffing, 42% of evolutions necessitated that at least one company deploy into the structure more than once.

Two factors affected the down firefighter’s viability in regard to removal: the time to remove the firefighter and the “condition” in which the down firefighter is removed. If the RIT can provide breathing air to the down firefighter and other companies operating can improve conditions (fire attack, ventilation, for example), the odds of viability are greatly increased. If there are serious injuries, then a second clock is ticking for the down firefighter. As with any other patient we treat, it is imperative that we get them to advanced medical care as quickly as possible. Removal time of a severely injured firefighter relates to viability in that the quicker the removal from the structure, the quicker treatment for injuries can begin.

Condition also encompasses removing the firefighter with all PPE intact and a positive supply of breathing air. As previously mentioned, it is imperative to ensure the compromised firefighter’s SCBA system stays in place during the removal process. To ensure this, it is vital to regularly check the firefighter’s mask to ensure a proper seal and no leaks. It is also vital to properly package the compromised firefighter, ensuring that all PPE remains in place. In 100% of evolutions in which the down firefighter was not viable, he was allowed to run out of air; low-pressure leaks occurred during removal. In 25% of the nonviable evolutions, the down firefighter removed was not only out of air, but key elements of his PPE (SCBA, mask, coat) were missing.

Saving our own is our most important mission. Fire departments across the world can implement these data-driven best practices to ensure that their firegrounds will be as survivable as possible. For the AFD, the lessons learned from Bowen’s death have been recognized and put into practice. We hope that you, too, will learn from these lessons and help to ensure that our mistakes will not be repeated. Rapid intervention is hard work and takes commitment to training, staffing, tactical proficiency, and your fellow firefighters. On July 28, 2011, our commitment was not sufficient. Today, we can proudly say that it is. Is your commitment sufficient?

TREY YOUNG, a 16-year fire service veteran, is a lieutenant in the Asheville (NC) Fire Department. He instructs in firefighter survival, rapid intervention, technical rescue, and truck company operations programs throughout the country. He is an instructor at the North Carolina Breathing Equipment and Firefighter Survival School and is a United States Marine veteran.