NEWARK’S TEXACO EXPLOSION—HOW IT COULD HAVE BEEN PREVENTED

FIRE REPORTS

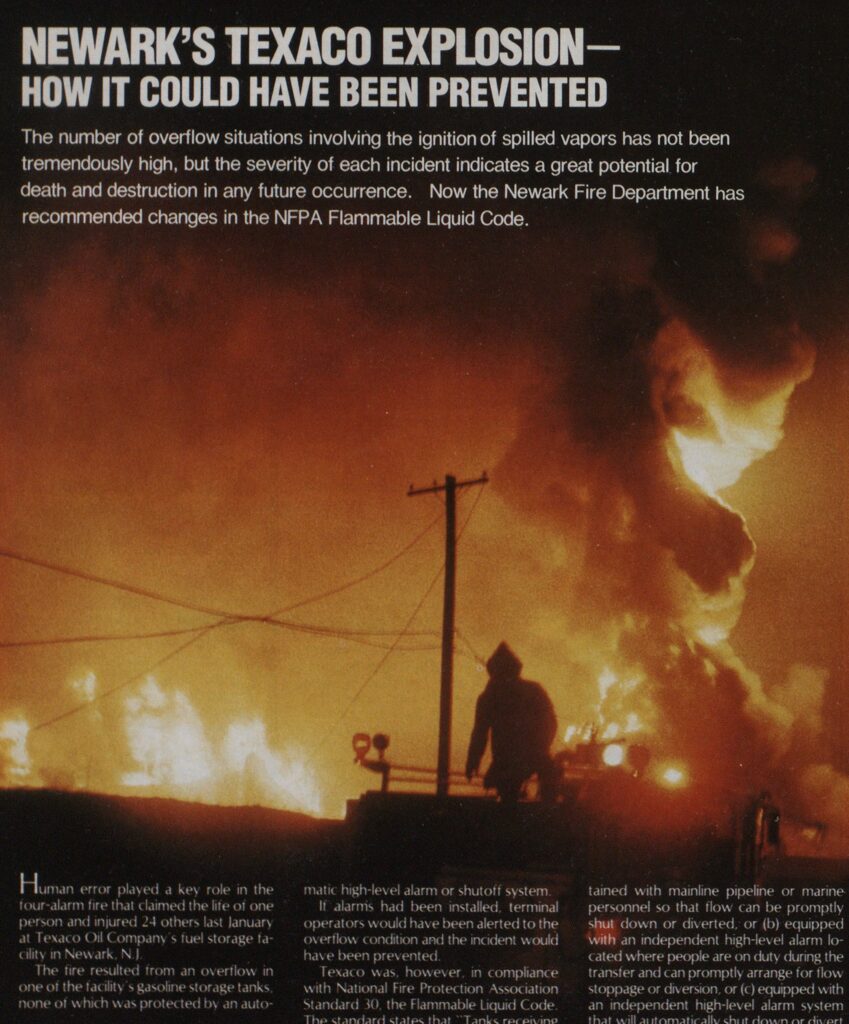

The number of overflow situations involving the ignition of spilled vapors has not been tremendously high, but the severity of each incident indicates a great potential for death and destruction in any future occurrence. Now the Newark Fire Department has recommended changes in the NFPA Flammable Liquid Code.

Human error played a key role In the tour-alarm tire that claimed the life of one person and injured 24 others last January at Texaco Oil Company’s fuel storage facility in Newark, N.J.

The fire resulted from an overflow in one of the facility’s gasoline storage tanks none of which was protected by an automat is high-level alarm or shutoff system.

If alarms had been installed, terminal operators would have been alerted to the overflow condition anti the incident would have been pres ented.

Texaco was, however in compliance with National Fire Protection Association Standard 30, the Flammable Liquid Code The standard states that Tanks receiving transter of Class 1 liquids from mainline pipelines or marine vessels and located where overfilling may endanger a place of habitation shall be either: (a) gaged at trequent intervals w hile receiving transter of product, and communications maintained with mainline pipeline or marine personnel so that flow can be promptly shut down or diverted, or (b) equipped with an independent high-level alarm located where people are on duty during the transfer and can promptly arrange for flow stoppage or diversion, or (c) equipped with an independent high-level alarm system that will automatically shut down or divert flow.”

The Newark Fire Department has recommended to the NFPA that the code be revised to have all three safeguard methods incorporated as a total system.

The Texaco storage facility chose to operate under the first option.

CHIEF

© 1983 Bill Clare. All right’s reserved,

Investigation showed that the tanks, gages and receiving lines were not checked at the prescribed hourly intervals and that there was an error in computing the amount of gasoline going into and out of the various tanks. No informational records were kept, thereby hindering the investigation process.

Newark Fire Department’s Bureau of Investigation estimates that approximately 150,000 gallons of super unleaded gasoline spilled over the top of a storage lank and into the diked area that surrounded four tanks, three of which were directly involved with the explosions. These three tanks were equipped with an internal floating roof, which keeps vapors from forming. The smaller, transmix tank, which is used during a transfer change from one distillate to another to avoid contamination, was heavily exposed but uninvolved, largely due to the fire department’s efforts. Foam and master streams were used to prevent the fire from spreading to the transmix lank.

The 6-foot dike was designed to contain any overage that the tanks might generate.

The probably ignition sc enario involved a gasoline vapor cloud, whic h drifted in a northwesterly direc tion from the Texaco tank farm to an incinerator at Central Steel Drum Company’s barrel refurbishing fac -tory 1000 feet away. Since gasoline vapors are heavier than air, they tend to hang low and travel, and the terrain gradient showed the Texaco tank level to be slightly higher than the Central Steel Drum facility. It is presumed that the incinerator ignited the vapors which then flashed back to the Texaco storage tanks, causing the resulting blast that was felt in parts of New lersey. New York and Connecticut. Several buildings at the barrel factory were destroyed before the ignited vapors jumped back to the gasoline tanks.

This hypothesis is bolstered by an eyewitness who slated that a blue flame in the area of the barrel factory seemed to travel back to the gasoline tanks just prior to the explosion.

The storage tank that overflowed, tank 67, had a capac ity of 1.8 million gallons of gasoline. The total capacity of all four tanks was in excess of 17,5 million gallons.

Prior to the incident, super unleaded gasoline had begun flowing into Texaco’s tank 67 via pipeline at 6:50 p.m. last Jan. 6. Thirty-eight thousand barrels (1.6 million gallons) were scheduled for delivery. This shipment had an expected completion time of 12:10 a.m. on Jan. 7.

To make room for this incoming shipment, Texaco began transferring 26,000 barrels (1.1 million gallons) from tank 67 to tank 5 at 7:20 p.m. Approximately 13,000 barrels were actually transferred.

Toward the time of the vapors ignition, events begin to jumble because of the lack of testing documentation. No written proof exists that the tanks were checked at the reported times of 9:30,10:30 and 11:30 p.m. It is probable that the overflow in the storage tank would have been prevented if the checks were actually made.

It was initially reported that at 11:50 p.m., during a check of the pipeline receipt, terminal operators discovered that tank 67 was overflowing through its vents. During a subsequent meeting with Texaco officials on Jan. 28, the time of the overflow discovery was changed to after midnight.

Although Texaco’s emergency procedures call for tripping emergency switches, notifying the pipeline company to shut off the gasoline flow, and notifying the Newark Fire Department, only the first two procedures were carried out.

Interviews held in the wake of the incident revealed that two of the three employees on site knew of no other emergency procedure than to call their supervisor.

The Newark Fire Department received the initial alarm from the Newark Radio Police at 12:16 a.m. on Jan. 7.

While en route, Battalion Chief Robert Miller reported a heavy volume of fire and requested an airport crash/rescue foam truck from Newark International Airport to respond.

Initial size-up from Deputy Chief Al McCrory showed many separate fires at the Texaco and Central Steel Drum sites, as well as a number of damaged railroad cars in Conrail’s nearby Oak Island Yard. Workers in all three locations sustained severe injuries and burns.

While first-alarm units were going to work, McCrory requested a second-alarm assignment to assist with the development of a relay operation to overcome the water supply shortage.

A third alarm was sounded to bring in additional equipment to protect the exposed Conrail facility south of Texaco. Fire from the burning tanks threatened the second and third rows of Conrail tank cars that contained hazardous materials. The rail cars in the first row suffered significant crushing damage, and had to be protected by master stream appliances.

The proposal submitted by Director John P. Caufield to the NFPA regarding modifications to Standard 30 (Flammable and Combustible Liquids Code) is still being voted on by the committee.

According to an NFPA spokesman, the committee sees these proposed changes as a major problem, and some of Caufield’s recommendations have been rejected.

Committee balloting is expected to be completed by June 24. The proposed changes will then be published and a comment period follows, during which the Newark Fire Department and the public at large can respond.

Any changes made to NFPA 30 are not expected to go into effect until around May 1984. “it takes an average of two years for a proposal to go from consideration to final acceptance,” said the NFPA spokesman.

The Coast Guard was notified of the potential for gasoline spilling into the Passaic River. The Newark fireboat, the John F. Kennedy, was called to the scene to guard against this possibility. However, the fuel was consumed by fire before it could reach the river.

A fourth alarm was called in at about 1 a.m. to reinforce the operations protecting the Conrail facility. During this time, Conrail worked to remove as much of its rolling stock as possible.

After extensive consultation with plant personnel, fire officials decided to let the gasoline fires burn out rather than risk the lives of fire fighters in an attempt to save already heavily damaged property. Two of the storage tanks had collapsed and there were pools of burning liquid. Tank 67 was severely damaged.

Due to the intensity of the fire and the extreme damage to the tanks and piping, it was impossible to mount a proper foam attack.

Although the pipeline transfer operation was terminated soon after the explosion, product at the transfer point was burning, and a hand line foam attack was mounted by fire fighters to put out the flames at that point and prevent a flow of flames through any piping that might have remained intact.

A prolonged program of exposure protection and brush fire extinguishment developed as winds pushed flames toward exposed propane tanks at an ARCO facility northeast of the Texaco tanks.

The fire was declared under control at 4:28 p.m. on Jan. 8.

The last flames from this tragedy disappeared on the morning of Jan. 9, leaving in its wake a multimillion dollar tragedy and a resolve on the part of Newark fire officials to see that no repeat be allowed to occur.