BY RONALD R. SPADAFORA

Microturbines are a relatively new technology being used for stationary energy generation applications. They are small-scale electricity generators that burn gaseous (natural and bio-gas) and liquid (gasoline, kerosene, and diesel) fuels. Their electrical outputs, in general, range from 25 to 500 kilowatts (kW), while conventional gas turbine sizes range from 500 kW to 250 megawatts. They are commonly the size of a refrigerator.

These machines can be used in electricity-only generation or they can capture the heat waste “cogeneration” of their turbine in producing electricity and transform it into usable combined heat and power (CHP). Additionally, “trigeneration” efficient microturbines are now being manufactured, providing combined cooling, heat, and power (CCHP).

Microturbines evolved in the 1950s from automotive gas turbines and turbocharger technology into sophisticated and complex equipment. They began initial commercial service in 2000. Onsite power minimizes a building’s total reliance on power plants. In a brownout or blackout, buildings having these devices may be able to maintain vital services until power is restored.

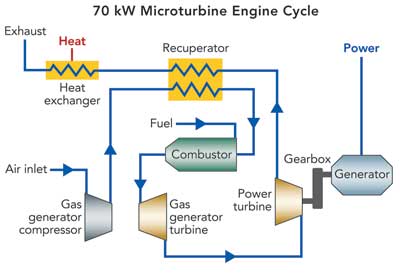

Some key components of CCHP microturbines are the compressor, recuperator, combustor, turbines, and generator. The compressor increases the pressure of inlet air, which passes through the recuperator (heat exchanger), where it is preheated. This air is then superheated inside the combustion chamber, where it mixes with fuel. Combustion gas expands and is delivered to one or dual turbines.

Two-shaft models use one turbine to power the compressor while the other drives the generator to produce electricity, instead of one shaft performing both actions. Exhaust products leaving the turbine pass through the recuperator, where heat is extracted to be used in the preheating cycle of air entering the combustion chamber. Finally, the remaining exhaust products can be used for air-conditioning, space heating, and hot water supply.

|

| (1) A double row of natural gas-fired microturbines atop a roof setback of a high-rise office building in Manhattan. (Photos by author.) |

CLASSIFICATION OF MICROTURBINES

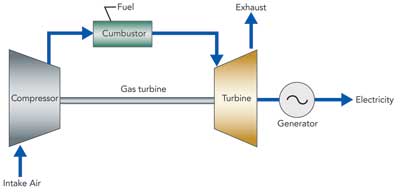

Unrecuperated (Simple Cycle). In an unrecuperated gas turbine, combustion gases power the turbine directly without requiring heat transfer to a water/steam cycle. Compressed air is mixed with fuel and ignited under constant pressure. These microturbines have lower efficiencies (15 percent) but have a higher reliability.

Recuperated. Recuperated gas turbines recover heat from their exhaust to increase the temperature of combustion and enhance efficiency. The fuel-to-electrical conversion is approximately 20 to 30 percent. Additionally, recuperated units can produce up to 50-percent fuel savings from preheating. Recuperated gas turbines can be cogeneration or trigeneration machines. Trigeneration microturbines push fuel efficiency upward to 90 percent while using only one primary energy source (natural gas).

|

| (2) A portable water mist fire extinguisher can be used to suppress incipient fires involving microturbines. |

LEGISLATION

Within the authority having jurisdiction (AHJ) of the Fire Department of New York (FDNY), Title 1 of the Rules of the City of New York (Chapter 50-Distributed Energy Resource Standards), for residential and commercial use was enacted in 2007 by a cogeneration task force headed by the Department of Buildings and FDNY. Known as “New York City’s [NYC’s] Microturbine Law,” it was written to ensure these alternative energy devices are installed safely. Although requirements existed for microturbines in buildings used for manufacturing, no major U.S. city had developed rules for their installation and use in residential and commercial occupancies.

|

| (3) A refrigerator size, 65-kW microturbine powered by natural gas. The microturbine provides a supplementary, alternative electrical energy source for the building. |

Under the law, microturbines approved by nationally recognized testing laboratories are allowed to be installed at residential and commercial buildings in various locations (i.e., weatherproof areas at grade, on roofs, and inside buildings within enclosed rooms). However, building owners have to obtain clearance from the utility company regarding their existing gas and electrical service as well as file a permit application with the Department of Buildings. The owner must also obtain a permit from FDNY to operate the equipment.

|

| (4) A manual electrical shutdown switch for a microturbine. For microturbine fires and emergencies, trip the switch if you can do it safely prior to firefighting operations. |

MICROTURBINE REQUIREMENTS AND FIRE SERVICE CONCERNS

Following are some key requisites taken from the NYC Microturbine Law that fire service administrators throughout the country should examine. The requirements can be used as a guide for fire department decision making during standard and code involvement. Working with code officials in enacting similar rules will enhance operations during microturbine fires and emergencies. Knowledge in this area will also benefit fire service personnel during building inspection and company drills.

| Figure 1. Unrecuperated (Single-Cycle) Gas Turbine |

|

| [Figure courtesy of the Renewable Energy Institute (http://cogeneration.net/simple-cycle-power-plants).] |

Policies pertaining to physical location, enclosure specifications, fuel type, electrical capacity, shutoffs, postings, and signage are just a few important issues to fully comprehend. (Author comments-in italics-after each requisite will help clarify the importance to the fire service.)

- Microturbine systems are to be installed in accordance with the requirements of AHJ construction codes, electrical and fire code, and National Fire Protection Association (NFPA) 37, Standard for the Installation and Use of Stationary Combustion Engines and Gas Turbines. Additionally, permit applications are to be filed with the local fire department’s fire prevention bureau.

Fire department permitting as well as an authorized Certificate of Fitness (C of F) holder (or similar qualification) should be required. The permit application includes a copy of approved plans and work permit issued by the Department of Buildings authorizing the installation of high-pressure natural gas-fired microturbine systems. The C of F person is trained by the manufacturer of the microturbine (or its authorized agent) to shut down the equipment in an emergency. - A fire department C of F holder shall be required on the premises during regular business hours.

During building inspection and familiarization drills, chief and company officers should seek out the C of F person to help provide a thorough examination of the microturbine system. The C of F holder should keep a bound log book on the premise to document operation. The log book should record daily inspection activity, the equipment’s hours of operation, and routine maintenance and repairs performed. Only a representative of the manufacturer or an authorized professional should service or repair microturbines; this must be done in accordance with the manufacturer’s instructions. - The owner shall obtain a service contract from the microturbine manufacturer or a qualified service company on installation of the microturbine and maintain it for the life of the system.

Emergency names, phone numbers, and additional contact information for the service providers should be posted and available on the premises. - The microturbine manufacturer shall establish a recommended schedule for preventive maintenance.

A preventive maintenance program should include the determined service intervals and specific responsibilities for the manufacturer and the end user. A copy of the preventive maintenance schedule should be available on the premises for review by fire department personnel. The program shall also document all work performed, the name of the person who performed the work, and recommendations following each service interval.

- Develop an emergency response plan detailing procedures that must be followed during fire and emergency (i.e., gas leak) situations.

It is strongly recommended that employees, occupants, and residents on premises where microturbine systems are installed be trained to alert the fire department and the C of F holder immediately at any sign of danger. Conduct training sessions periodically for all personnel and occupants emphasizing methods for the fast and safe evacuation of the building in conjunction with shutting down the microturbine system.

- Microturbine systems are to be in a physical location so that they are readily accessible for maintenance, repair, and firefighting.

Microturbines may be on a roof or roof setback, outdoors at ground level on grade, and inside buildings. Minimum clearance requirements for all system components include walls and parapets, exhaust terminations/chimneys, and building openings.

Minimum clearance requirements for a microturbine system outdoors at grade level include subway entrances/exits/vents/openings, aboveground flammable/combustible liquid storage tanks/vents/fill lines, lot lines, and motor vehicle parking spaces.

Readily accessible for firefighting is, of course, the significant element here for the fire service. Ensure microturbines are accessible to firefighters, needed equipment, and hoselines. Include their locations in computerized databases for use by responding units.

Microturbines shall also be provided with adequate protection from theft, tampering, and unauthorized use. Access to microturbine systems should be restricted by locked doors but shall be readily accessible to fire service personnel. Microturbines installed outdoors on grade shall be adequately protected from vehicle impact. - Microturbines inside a building shall be enclosed within two-hour fire resistance rated walls.

Is the enclosure for the microturbine unsubstantial or breached? Containment during a microturbine fire is essential for a safe and successful operation. Take necessary enforcement and referral action where required. - Microturbines inside a building shall be protected by a sprinkler system or provided with an equivalent fire suppression system.

Evaluate the extinguishing equipment installed to protect microturbines from fire. Is the system being maintained properly? If an “equivalent” fire extinguishment system (water mist, halocarbon, or inert gas) is being used for fire suppression, chief and company officers should familiarize themselves and their members with the unique features of this technology. Firefighters should use dry chemical, carbon dioxide, or in-house water mist portable fire extinguishers to put out incipient fires in and around microturbines. - Microturbines inside a building shall provide sufficient mechanical ventilation.

The ambient room temperature should not exceed 104°F. High temperatures can negatively affect the efficiency of microturbines, so take necessary referral action. - Microturbines inside a building shall provide a gas detection system and alarm that annunciates in a supervised location; gas detectors shall also trip (shut down) the microturbine.

During the building inspection, spend additional time examining the major components of the detection, notification, and activation components of the microturbine system. Ask questions and take photos for use during company drills. - Microturbines inside a building shall provide adequate lighting.

Take necessary referral action to ensure this requirement is in accord with your AHJ. - Microturbines inside a building shall not have gas meters within the same room.

Equipment not directly associated with the microturbine system includes but is not limited to gas meters and shall not be permitted within the microturbine room. Take the necessary referral action. - Microturbines inside a building shall not have combustible materials and fuels stored within the same room.

Rubbish and other combustible waste should not be allowed to accumulate anywhere inside the building, let alone the enclosure where the microturbine is. This is a fire hazard that should not be tolerated. Have all rubbish and other combustible waste promptly removed from the premises. - A structural evaluation regarding the method of support for the microturbine system shall be performed by a licensed engineer for existing buildings.

This structural analysis should include measures necessary to mitigate vibrations. - Microturbines shall use natural gas.

Microturbine systems in the City of New York use natural gas at a low inlet pressure and boost it to high pressure (greater than 15 pounds per square inch) en route to the combustor. Natural gas is a gaseous fossil fuel consisting primarily of methane but includes significant quantities of ethane, butane, propane, carbon dioxide, nitrogen, helium, and hydrogen sulfide. The methane content can range from 87 to 96 percent. Because of the large methane content in natural gas, it is assumed to behave like methane. Methane has a lower explosive limit of five percent in air and an upper explosive limit of 15 percent.

Processed natural gas is tasteless and odorless. However, before gas is distributed to the consumer, it is odorized by adding small amounts of mercaptan, dimethyl sulfide, and other sulfur compounds to assist in leak detection. Breathing in natural gas in small amounts is not harmful, but natural gas is a simple asphyxiant that can kill if it displaces air to the point where the oxygen content will not support life.

Natural gas is a flammable gas (autoignition temperature of 998°F) that can ignite as well as explode. It is lighter than air, having a specific gravity of 0.60, which is lower than that of air (1.00). The gas rises and tends to escape into the atmosphere. However, when natural gas is confined within a building or an enclosed space, concentrations can reach explosive mixtures and, if ignited, result in blasts that can collapse structures. - No self-certification is allowable concerning inspections of gas piping servicing the microturbine; the fire department will perform inspections.

Self-certification is a convenient way for the construction industry to monitor its work. However, it is not an ideal situation for the fire service. Experienced fire department personnel designated to inspect gas piping supplying microturbines will enhance safety by ensuring the installation is in accord with AHJ codes and standards. - Remote and manually controlled emergency gas shutoff valves are required outside the door to the microturbine room as well as at a supervised location.

Know where these two locations are in relation to the microturbine. This information should also be included in your department’s computer databases for responding units. - Gas shutoff valves and controls shall be clearly identified with signage.

- Take the necessary action regarding fire prevention enforcement procedures to seek compliance with this vital requirement.

- There must be a gas shutoff valve diagram conspicuously posted on the door or entrance leading to a microturbine indicating the location of all automatic and manual gas shutoff valves.

Chief and company officers must familiarize themselves with the layout and run of the natural gas piping system and shutoffs to microturbines. This is critical information to retain and will be useful during fire and emergency incidents. A posted diagram will facilitate this need. Additionally, as part of the engineering design, an automatic gas shutoff valve shall be activated by a malfunction signal from any microturbine system component. - A “High-Pressure Gas” sign shall be posted on or in front of the microturbine and on the outside of all doors accessing any microturbine room.

This is similar to the gas shutoff and controls; take necessary enforcement action. - A microturbine is to have a maximum 500 kW or less capacity.

Examine postings and labels on the microturbine to determine the maximum electrical capacity of the machine. - Total nominal electrical capacity for all microturbine systems within a single building shall not exceed 2,000 kW.

When an emergency shutdown of a microturbine is required, the disconnect switch located immediately after the branch connection providing dedicated service to the system should be turned off manually. Do not touch electrical conductors and cables inside and connected to microturbine systems.

|

| (5) An access door to the microturbine. Note the fuel (natural gas) shutoff valve location and pipe run diagram, emergency gas shutoff, and signage on the door. |

STANDARD OPERATING PROCEDURES DURING FIRES AND EMERGENCIES

Do not use conventional water-based fire extinguishing agents on or in the vicinity of energized microturbine equipment, conductors, cables, and battery banks. Consider the need for alternate (i.e., dry chemical, carbon dioxide, and water mist) fire extinguishment agents. Take special care even after high-voltage electrical equipment is disconnected. It is still possible for the microturbine to retain residual power and an electric charge for an indefinite period of time. Microturbines exhaust ducts can reach high temperatures that are hot enough to cause severe burn injuries if touched and fires if they come in contact with combustible materials.

|

| (6) A methane gas sensor inside a fireproof microturbine enclosure. |

When microturbine systems use lead-acid battery packs to store power, there is always the danger of electric shock. Additionally, the potential release of sulfuric acid as well as flammable (hydrogen) and toxic gases is ever present.

| Figure 2. Recuperated Gas Turbine |

|

| [Figure courtesy of the Electric Power Research Institute (www.wbdg.org/resources/microturbines.php).] |

The following list includes some of the basic strategies and tactics to employ during microturbine emergencies; it is not all encompassing. The incident commander and operating units still must employ traditional size-up techniques to gather additional pertinent information.

- Immediately cease operation of the microturbine system and related equipment.

- Do not use any tool or turn any electrical switch that can cause a spark in the area of a natural gas leak.

- Turn off the microturbine system from a distant location, if feasible.

- Shut down and lock the electrical disconnect switch.

- Close all natural gas shutoff valves.

- Ventilate the area.

- Use natural gas meters to analyze air concentrations as well as to check for leaks at piping and valve connections.

- Do not turn the microturbine or any gas service back on.

- Request the response of gas and electric utility personnel.

|

| (7) An electrical disconnect (foreground) installed between the microturbine and the building electrical service panel. |

Microturbines can provide electricity, heat, and cooling for usable purposes. This can be very cost effective by reducing the amount of energy needed from a utility company. Microturbines additionally improve your environment by reducing the release of greenhouse gases and lowering the demand on the electrical grid.

This article provides a brief overview of some of the requirements for microturbine systems in my AHJ. I strongly recommend that you research your applicable codes and standards.

|

| (8) A manual shutoff for the natural gas supply is adjacent to the microturbine. |

REFERENCES

1. Capehart, Barney L, PhD, CEM. “Microturbines,” National Institute of Building Sciences (Whole Building Design Guide). Updated August 31, 2012. Retrieved April 5, 2012 from http://www.wbdg.org/resources/microturbines.php.

2. Material for the Examination for Certificate of Fitness for G-92 Supervision for High-Pressure Natural Gas Fired Microturbine Systems. New York City Fire Department Publishers. January 15, 2008.

3. The Official Rules of the City of New York 1 RCNY §50-01 (CHAPTER 50-Distributed Energy Resource Standards). “Requirements for the Installation of High-Pressure Natural Gas-Fired Microturbine Systems.” New York Legal Publishing Corporation.

RONALD R. SPADAFORA is an assistant chief with the Fire Department of New York.

Microturbine Advantages

- Combined power and heat capabilities.

- Cost savings (reduces peak demand, therefore lowering demand charges).

- Power reliability (especially during blackouts, brownouts, and surges).

- Standby power reduces worker downtime.

- Usage of waste fuel (biogas).

- Can be an alternative to diesel generators.

- Low emissions.

- Lightweight.

- Compact size.

- Can be located on sites with space limitations.

- No vibrations.

- Less noise than reciprocating engines.

- Small number of moving parts.

Fire Engineering Archives