Major Chemical Incident Controlled by Coordination and Cooperation

HAZARDOUS MATERIALS

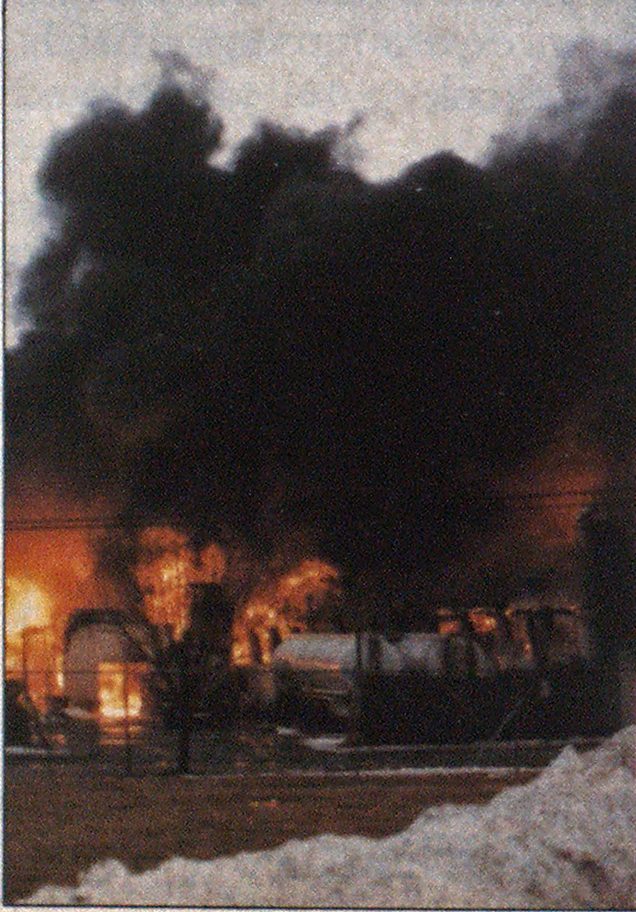

Training, pre-fire planning, and a strong mutual-aid system were challenged by disrupted water supplies, high winds, and toxic fumes at a chemical plant explosion and fire in Middlesex, NJ, last February. Forty-two fire companies and over 700 firefighters were required to bring the incident under control.

Middlesex is a 272-square-mile community of 13,400 people in north central New Jersey. Fire protection is provided by the allvolunteer Middlesex Fire Department, consisting of four independently-owned fire companies, three with one engine, and one with a ladder and rescue/air cascade truck. Each company has 25 members operating under the direction of a company captain. Each company answers to a single fire chief and two assistant chiefs.

Shortly before 10 A M. on February 12, 1985, a commercial tank truck arrived with a delivery of alkyd at the Chemray Coatings Corporation plant. Alkyd, an alcohol-based resin, is used in the manufacture of latex paints, and, despite a flash point of 105°F, has to be heated to 130°F to lower its viscosity to allow it to be pumped into the plant’s holding tanks.

While the tanker was pumping from the plant’s east side loading dock into a mixing room in the center of the building, a coffee truck arrived in the west side parking lot and most of the plant’s 18 on-duty employees went out for a break. Workers passing by the closed door to the mixing room were reported to have noticed a liquid seeping from under the door and notified a plant supervisor, who, in turn, opened the door to investigate. He was immediately overcome with nausea from the fumes, and ran to the bathroom in the front of the building. The plant was simultaneously rocked by a violent explosion, followed by fire and more explosions. A Chemray employee who was entering an office adjacent to the mixing room was blown out a window in the rear of the plant by the force of the explosion. A visiting copying machine repairman working in the same office never escaped. All other occupants made their way out of the building through the rapidly progressing smoke and fire conditions.

Multiple calls were received by the Middlesex Boro Police Department regarding the explosion, including a radio report by one of their passing patrol cars at 10:01 A.M. that drums were exploding and flying into the air. The Middlesex Fire Department was dispatched by the police using their siren and home alert receivers, and Fire Chief Michael Kozik arrived from his home two minutes later.

Photo by Pete Gordon

Chief Kozik found the one-story, 225 X 200-foot sprinklered brick and concrete block structure already fully involved with fire. Exploding 55-gallon drums were rocketing 150 feet into the air.

Exposures

The Chemray plant is located in a mixed residential, commercial, and industrial neighborhood. Lincoln Blvd., 35 feet wide, is to the north of the Chemray plant, and six Conrail and New Jersey Transit railroad tracks, running parallel to Lincoln Blvd., are to the south. Several homes are located 75 feet east of the plant.

On a 150 X 210-foot lot 20 feet west of the Chemray plant is the Springfield Steel and Fibre Drum Company, a drum reconditioning plant. Also on the lot is a 150 X 50-foot one-story concrete block plant along the rear of the lot; a 75 X 25-foot, lV2-story brick building in front of the block plant; and a 30 X 20-foot, one-story concrete block auto radiator repair shop. This area also stored hundreds of empty 55gallon drums, some stacked eight high. Winds blowing westward at 30-40 mph with gusts of 55 mph had already sent burning drums into the reconditioning plant, setting it on fire. Chemray employees informed Chief Kozik that tank trailers parked along the east side wall of the plant contained toluene.

Photo by Pete Gordon

Beyond the reconditioning plant is a windowless l 1/2-story, sprinklered, concrete block, 50 X 150foot Garden State Floor Tile Company, and beyond this is a Chemray warehouse, containing paints and other flammable liquids. The most serious exposures, despite the distance from the fire, were a group of chemical plants located on the other side of the railroad tracks on the south. The Marisol plant, which has a reclamation process for volatile oils and fluids, is directly across the tracks, and the Inmont Corporation, a producer of nitrous cellulose to manufacture guncotton and gunpowder, is just east of that. Beyond these two plants is Union Carbide’s plastic resins manufacturing plant. Railroad tank cars containing sulfur were on the tracks between the plants and the fire.

Chief Kozik transmitted a signal for a working structural fire, and immediately requested mutual aid from the adjacent towns of Bound Brook and Dunellen, which responded with one engine and one ladder each, and asked that the county mutual aid coordinators respond to the scene as well. Also volunteers, the coordinators’ role is to assist the incident commander by providing any needed resources from their counties, and arranging for move-ups to cover stations.

Police and firefighters already on the scene were directed to begin the evacuation of surrounding businesses and homes. Middlesex Fire Inspector Michael Duffy ran to the rear of the Chemray building and found the burned and bruised Chemray employee who had been thrown through the window wandering dazedly about.

Strategy and tactics

The first-arriving engine, Lincoln Hose Company, was directed by Chief Kozik to hook up to a hydrant at the corner of C Street and Lincoln Blvd. The second engine, housed just 150 feet north of the fire scene, hooked up to a hydrant at Lincoln and B Street, directly across from the Springfield Drum plant. Middlesex and Bound Brook’s 100-foot ladders were placed at the east and west ends of the fire building, respectively, for deluge operations. With water available from a six-inch main on the north side and a teninch main on the south (fire) side of the street, Chief Kozik’s strategy was to cool two tank trailers containing toluene located in Chemray’s east side lot along the building wall, to provide a water curtain, and to hit the main body of fire with the elevated master streams.

This strategy had to be changed suddenly as the hydrant was opened and the engine company reported a meager flow of approximately 500 gpm. Water was then seen cascading from ruptured sprinkler piping at the northeast corner of the fire building. This lowered the pressure in the 10-inch main.

Firefighters were sent under the protection of hoselines to close the three sprinkler control valves, but were unsuccessful as the piping had been damaged below the valve level by the explosion. With his water supply severely hampered, Chief Kozik ordered the Middlesex ladder removed from the parking lot across from the fire and placed closer to the northeast corner of the plant to cool the toluene tankers. Bound Brook’s ladder unit was sent to the south side of the building on an access road running along the railroad tracks (rail traffic had been shut almost immediately after the explosion) where Piscataway’s snorkel joined them. Both were supplied by engine companies hooked up to hydrants on a 48-inch main located south of the chemical plants. Together, they utilized elevated streams to fight the Chemray and Springfield Drum plants’ fires and to protect exposures.

Chief Kozik set up his department’s station wagon just east of the fire as the initial command post. Joining him was Middlesex County Fire Coordinator Dan Kiuinski, while Somerset County Fire Coordinator Doug Rue set up a command post for his county’s units on the west side of the fire. (The predominantly rural Somerset County would prove to be an excellent source of tankers.) Middlesex Fire Department’s First Assistant Chief Louis Moscetti, Jr., was dispatched to the west side of the fire scene to coordinate water supply and manpower with the Somerset County coordinator, while Second Assistant Chief Kenneth Pukas oversaw the operations along the railroad tracks on Exposure 3 : side of the fire building.

Representatives of Middlesex’s Office of Emergency Management (OEM) arrived on the scene and provided Chief Kozik with a detailed diagram of the Chemray plant, which listed the names, locations, and properties of all hazardous and flammable materials contained there. Under New Jersey’s Right-to-Know Law, OEM team members had entered Chemray six months earlier and gathered the information to prepare response books for field use. In addition to providing the information at the scene, the OEM also activated their disaster control center in the basement of Boro Hall. Thirty telephone lines there were staffed by representatives of the OEM, Police, and Health Departments. Innumerable inquiries from local residents, concerned relatives of local residents, and the media were handled by the disaster center.

Mutual aid tankers began arriving. A 2,000-gallon Porta-Tank was set up at the intersection of C Street and Lincoln Blvd., supplementing Lincoln Hose’s water supply as it fed the nearby ladder stream. Two other tanks were later set up and a total of 13 tankers were eventually involved in shuttling water from hydrants on another grid system located a half mile away. This action provided an adequate water supply along the northern fire front. Two relay pumping operations were also established using large diameter hose. One drafted from a creek approximately 1,300 feet west of the fire building using five-inch hose in a relay to an engine company on the northwest corner of the fireground. The other relay used four-inch hose and three engines to pump from hydrants 2,500 feet from the fire.

With an adequate water supply established and equipment on three sides of the fire, a more aggressive attack plan was begun. Under the protection of hose lines, the stillattached alkyd tanker was shut down, unhooked, and driven to the east side of the lot (hose lines prevented moving it completely away). An 85-foot ladder was moved from the apparatus staging area to the fire building’s northwest corner for deluge operations.

Firefighters with l 3/4-inch handlines began to enter the Springfield Drum lot and approach the Chemray warehouse. High winds made for poor stream penetration. Acetylene tanks in the auto radiator shop caused a fierce fire condition within that structure. Fire also erupted on the asphalt-shingled roof of the Garden State Tile Company and burned off the plastic skylights. The fully involved Springfield Drum buildings caused heavy heat conditions in the tile storage building as well as in the Chemray paint warehouse beyond it. Firefighters were ordered onto the roof and inside Garden State Tile. The sprinklered paint storage building was protected by using pike poles to set off several sprinkler heads, and then supplying the Siamese with an engine company. The advance of the main fire was stopped at the tile plant.

Approximately two hours after the initial explosion, Chief Kozik moved his command post inside a nearby utility sub-station 600 feet east of the Chemray plant. He was joined there by representatives from state and local police, the Middlesex County district attorney, the New Jersey Department of Environmental Protection, the federal Environmental Protection Agency, the emergency management team of Middlesex’s OEM, the Middlesex County Civil Defense, and rescue squad Captain Joseph Coren, who coordinated emergency medical services at the scene.

Continued on page 37

Photo by Pete Gordon

Continued from page 32

Chief Kozik, with his firsthand knowledge of fire extent, resisted suggestions by command post members to evacuate a much larger area around the fire and shut down utility lines (gas and electric) along Lincoln Blvd. Instead, the evacuation area was increased slightly due to a wind shift, and gas service to individual buildings in the area were shut off by Public Service Electric and Gas crews.

Meanwhile, air quality tests performed by the Department of Environmental Protection showed traces of toluene, methyl ethyl ketone, isopropyl alcohol, and Nbutyl alcohol. All were in very small quantities and posed no health hazard. Still, some residents downwind later complained of eye and throat irritations, and firefighters maintained use of selfcontained breathing apparatus (SCBA). It was later surmised that the intense heat of the fire destroyed most of the chemicals involved in the fire. The wind dispersed the fumes, and the rain in turn “washed” the smoke. At 2:15 P.M., the fires at Chemray and Springfield Drum plants had subsided sufficiently to allow a closer attack, and they were declared under control.

As the operation wore on, the logistical concerns of fuel, food, and fatigue stepped in. Portable radios began to fail. The ladies’ auxiliary served food to firefighters at the nearby fire station, and fuel tankers from Middlesex’s Boro Garage and Somerset County refueled apparatus on the scene. The two mobile cascade systems refilled nearly 80 SCBA cylinders, and a commercial fire equipment firm had to be called in to refill even more.

At 5 P.M., evacuated residents, who had been sheltered at the high school, a recreation center, and an Elks Lodge, were allowed back to their homes, and mutual aid companies began to take up. Middlesex fire equipment remained on the scene until after midnight. A firewatch was maintained overnight. Unstable walls made a complete overhaul too dangerous until bulldozers could be brought in to topple them safely. With the exception of the copy machine repairman, whose body was found at approximately 5 P.M., injuries at the fire scene were relatively minor. The Chemray employee who was blown from the building was released from the hospital the next day, and one other employee suffered a head laceration that required treatment. Two civilian onlookers, two police officers, and ten firefighters were also treated, the latter suffering primarily from prolonged smoke exposure and exhaustion late in the operation.

Photos by Pete Gordon

Summary

At critique sessions held afterward, a common complaint was that of excessive radio use. Transmissions were described as nearly continuous during the height of the fire, despite the availability of the two county bands. Impressing all participants was the detailed pre-fire information Middlesex firefighters had available. “The Right-toKnow Law is only as good as your agency makes it,” commented Chief Kozik. Operational improvements planned for future incidents include the use of a mobile command post van that will interface with Middlesex’s Disaster Control Center. Staffing will be by members of the OEM and any of several former Middlesex Fire Department fire chiefs, who have the knowledge required to act as liaison with the incident commander.

An investigation into the cause of the fire revealed that overflow alarms in the mixing room of the plant did not sound, nor did fume detectors automatically set off explosion-proof fans and vents in the room. It has not yet been determined why these safeguards failed. The copy machine technician died of burns almost immediately, the probable ignition source of the explosion being one of the machines in the office where he was working. The Chemray plant and all three Springfield Drum buildings were destroyed, with the total loss of the fire estimated at $4 million.

Chief Kozik, who had been chief for six weeks at the time of this incident, and his all-volunteer force of firefighters handled the largest incident since the establishment of their mutual aid system, using a combination of detailed pre-incident planning and well-rehearsed fireground tactics to contain and conquer this fast-moving and heavily fueled fire.