KENNEDY SPACE CENTER FIRE SERVICES

Wide/World Photos

NASA’s John F. Kennedy Space Center stretches out over 140,000 acres of land and water on Merritt Island, just off Florida’s eastern coast. Of this vast acreage, all but the operational areas of the space center are used as a national wildlife refuge. Unbroken stretches of vegetation and marshland border the parkways that carry workers and visitors into the launch complex and industrial area. The highly charged atmosphere of the restricted operational areas provide a sharp contrast to the pacific stillness of the gamelands. Security is tight. Sterile, nondescript buildings provide few clues to their content or purpose. This is the doorway to outer space.

The most impressive edifice at the Kennedy Space Center is the Vehicle Assembly Building (VAB) at Launch Complex 39, where the space shuttle is constructed and refurbished. One of the largest buildings in the world, the VAB stands 525 feet high and covers 8 acres. An American flag is painted on its facade. Locals say each star is distinctly visible from as far away as 5 miles.

In the shadow of the VAB, also part of the launch complex, is Fire Station 2. Richard Firstner, a captain at the station has been a fire fighter at KSC for almost two years. He still regards his employment with a measure of awe.

“I consider myself very lucky,” he comments. “Out here we deal with many different and exotic things, things you wouldn’t find in ordinary communities — like the fuels and ordnance.”

The fuels Firstner refers to are uncommon. Hypergolic propellants (materials that ignite spontaneously when combined), monomethyl hydrazine (MMH) and nitrogen tetroxide (N2O4) are used to power the space shuttle’s orbital maneuvering system. This system allows the spaceplane to adjust its path, rendezvous and slow down for its return to earth.

Since the fuel (MMH) and the oxidizer (N2O4) ignite on contact, these fluids are stored in well-separated locations on the southwest (MMH) and southeast (N204) corners of the launch pads. They are fed through transfer lines to the launch pad and on to the rotating service structure umbilical system. The rotating service structure provides protected access to the orbiter for prelaunch servicing.

“We can have fire even when these chemicals don’t ignite with each other,” says Firstner. “If the monomethyl hydrazine comes in contact with simple things like rust or air, it ignites. You’ll have fire immediately.”

Cryogenic propellants, the supercooled liquid hydrogen and liquid oxygen used by the space shuttle’s main engines, are processed and stored here also. The liquid hydrogen is held at —423° in a storage tank at the northeast corner of the launch pad. The liquid oxygen is held at -297° in a storage tank at the northwest corner. The propellants are fed to the launch site through vacuum-jacketed transfer lines.

Ordnance (a variety of explosive-actuated devices) is used for most solid rocket booster functions, from launch pad release to payload separation. Explosive bolts fasten the solid rocket boosters to the mobile launcher platform. These boosters are fired off and released as the booster engines ignite.

The entire launch complex —with its bounty of hazardous materials —is the province of Fire Station 2. Originally designed for the Apollo Lunar Landing Program, the launch complex is now devoted to space shuttle operations.

Facilities at the launch complex include the VAB; the orbiter processing facility, a specialized hangar where the orbiter is stripped of ordnance and fuel residues, tested and refurbished; the shuttle landing facility with its 15,000-foot runway; launch control center; the Crawlerway, which is as wide as a turnpike and over which the space shuttle rides on its crawler-transporter to the launch site; the press site; and other supportive structures.

Fire Station 1 covers the space center industrial area, 5 miles south of launch complex 39. Here, detailed operations connected with prelaunch processing and testing of space vehicles takes place.

A year-round nerve center, the industrial complex includes the headquarters building, the immense operations and checkout building which houses offices, laboratories, astronaut quarters and a spacecraft assembly facility, the central instrumentation facility where information and communications are received, recorded and interpreted, and a variety of smaller, highly specialized facilities.

“In some ways we’re just like any other fire department,” comments Roger Tome, assistant chief at Fire Station 1. “Though no one actually lives here, it’s a working environment like you’d find in any town, with office buildings and all.”

There the similarity ends. Even as Tome spoke, space center workers at the hypergol maintenance and checkout facility prepared hypergol-fueled modules for storage. This facility, the primary location for hazardous operations in the industrial area, occupies a group of buildings in a remote area of the complex, 8 miles south of the launch pad.

“We use these fuels in different buildings in the industrial area where we test the engines,” explains Firstner. “We re specially trained to fight hypergolic fires because they burn so much hotter and quicker than normal fires. More like an explosion.”

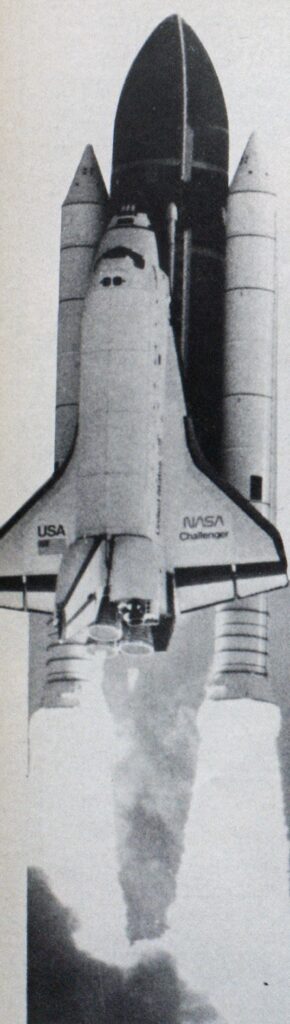

Fire Detection, Suppression Aboard the Challenger

The Challenger’s fire detection and suppression systems use four portable halon fire extinguishers and three fixed extinguishers.

Nine early warning smoke detectors activate a warning light on the control panel and a siren, which indicate a significant increase in gaseous or particulate products of combustion inside the orbiter.

Two smoke detectors in each of the three avionic bays activate similar signals to warn the crew to take action. There is one halon 1301 extinguisher in each avionics bay.

If the sensors detect smoke in the crew compartment or behind the electrical panels, the crew will use one of the portable extinguishers, which are also used as backups for the avionics bay extinguishers. The portable extinguishers have tapered nozzles that fit into fire holes on the electrical panels to extinguish fires behind the panels.

The fire suppressant halon 1301 effectively breaks the chemical chain reaction in a flame instead of smothering it. It takes less than 6 percent of the chemical to suppress a fire.

Photo by Gerard R. DeFranco.

The specialized training is done on the job. To be hired, fire fighters must be state certified. Though crash-rescue experience is desired, it is not mandatory. “There’s really nowhere else you could get the specific experience you need out here, explains Firstner, “so this is our training ground.”

Finding time for training is not easy when a shuttle launch is imminent. The two fire stations not only provide ground support for fire and hazardous operations at the space center and emergency coverage for areas where workers may need rescue, but also must support operations specific to the launch.

The stations operate on a three-shift, three-platoon basis. Platoons A, B and C each consist of 24 fire fighters — 12 men per station, four per shift (three fire fighters and one officer) at all times. A total complement of 101 people includes fire shuttle planners, fire inspectors and combat fire fighters.

If extra help is needed, off-duty crews are paid to work overtime. On launch day, two shifts are on duty. Operations run one after another for at least 24 hours, calling upon the crews of both stations.

“Launch time is the most hectic because we have our normal operations plus everything we must do for the launch, comments Firstner. “We re asked to cover the landing strip, for example, when the astronauts practice touch-and-go landings. They go up, then come down again, simulating a shuttle landing here. We go out with the crash trucks in case something goes wrong.

“A few days before launch they do a flight crew emergency egress test. The flight crew goes to the pad and simulates an emergency condition where they have to leave the launch site. We help with their egress.

“We also provide continuous support when systems are readied at the pad. They’re fired up, checked out, and readied for launch. Liquid oxygen and liquid hydrogen are loaded into the orbiter’s external tank. Hypergolic fuel is put on board. The ordnance is put in place and activated. It’s all pumped up, ready to

“We keep armored personnel carriers out at the launch pad, so we go out there several times a day to start them up and make communications checks.”

One of the armored personnel carriers is kept at the slidewire bunker inside the pad. The slidewire (emergency exit system) provides an escape route for crew members onboard the shuttle and on the orbiter access arm of the fixed service structure until the solid rocket boosters ignite.

Five slidewires extend from the access arm to the ground on the west side of the pad. A stainless steel basket lined with Nomex webbing hangs from each wire for ready entry. Each basket holds three people. The baskets slide down the wire to the landing zone area in 35 seconds. Upon landing, the flight crew boards the armored personnel carrier and leaves the launch site.

The other armored personnel carrier transports the fire rescue crew into the pad and, if necessary, is used to take the astronauts out of the shuttle.

Five hours before launch, fire rescue team members man a roadblock which is set up within a mile radius from the launch site, the closest manned location during the launch. They do not leave until the launch has been completed.

Near the press center, the main roadblock precludes visitors from entering the operational areas. “This is where we stage our fire apparatus during the launch,” explains Fire Chief Terry Dickerson, “just outside the fallback area.”

Crew are assigned to long-distance support operations, as well. In the event of a contingency (unforeseen) landing, a five-person crew is sent to the TAL (transatlantic abort location) site in Dakar, West Africa, for each shuttle launch.

When crews are not covering prelaunch operations, the schedule is generally uneventful. We don’t get many emergency calls,” observes Firstner. “Usually we just answer alarms. There aren’t many real emergencies here.”

The reason for this, explains Dickerson, is the space center’s fire inspection and prevention system.

I can honestly say I’ve been on more fire calls in a single day in the municipality I came from than I’ve been on out here in the past two and a half years” he comments. The space center is unique. Its protection devices and the impact of fire services on operational safety— our inspections, our requirements, the people we have on site when hazardous operations go down — give us almost total control over any fire problem”

A permit is required before any hazardous operation takes place. Any discrepancies noted must be corrected. “When an operation goes down, we can have as many as four people there with a fire pumper,” says Dickerson. “We actually have fire fighters standing by with extinguishers for welding operations. Should there be any chance of a spark, we want to be on top of it.”

“The Kennedy Space Center complex was built for safety, which makes our job easier,” says Firstner. “When we answer alarms, it’s usually trouble in the system. We check it out and alarm technicians service the system immediately. There’s virtually no gap in protection, so we don’t have the worry that something might go undetected.”

There’s only so much you can do in the private sector, observes Dickerson. “Here, fire protection systems are incorporated into the initial design and construction of our facilities. Heat-activated detectors and smoke detectors, halon systems, sprinkler systems and dry chemical systems must be in place. And we have a control center monitored 24 hours a day with all alarms reporting directly to it.”

Station 2 responds to the launch complex with two pumpers and two crash trucks, an elevating platform and a minipumper. Their assignments often overlap, for example, when the 85-foot platform is needed.

“We use the platform for high-rise buildings. It carries no water. The water is supplied by pumpers,” explains Tome. “The engines carry a limited amount of water and hook into hydrants; they respond to emergency landings at the strip. The minipumper is our rescue vehicle — we use it on the landing strip and when we have to get the astronauts out. It carries life support equipment and the Hurst tool.”

Fire services uses two Hurst tools, one for each station, carried on the minipumpers. The RAMP vehicle, a brown pickup truck, transports fire fighters back and forth to standbys and emergencies at the landing strip. Its cargo consists of bottles of halon.

By now, each shuttle launch is a repetition of the last with some modifications, the same milieu.

The shuttle arrives at the launch pad and is mated to the supporting pad facilities. Power is applied. Launch readiness testing is completed, then hypergolic and cryogenic load preparations are made. When these nonhazardous countdown preparations are finished, the pad is cleared.

Hazardous operations are completed – servicing the hypergolic, highpressure-gas, and fuel-cell cryogenic systems and payload fluid. The vehicle is put on standby at T-minus-2 hours (two hours before launch) in readiness for the launch.

At the designated time, the orbiter’s liquid and solid rockets ignite and burn simultaneously, generating 6.7 million pounds of thrust. After boosting the shuttle to an altitude of 31 miles in two minutes, the exhaused rockets detach and drop into the ocean. The temperature in the combustion chamber of the main engine climbs to 6000° as the orbiter continues into space. The external tank is jettisoned just before the shuttle enters orbit.

Those that gathered to observe the launch silently survey the billowy white clouds that remain long after the orbiter is out of sight.

The fire services team assigned to postlaunch operations escorts the safety contingent onto the launch pad. The “safing” procedure begins. The team extinguishes spot fires and surveys for damage, checking all systems for ruptured lines. This finished, they head back to the station.

The orbiter circles and recircles the earth. The atmosphere, once electric, remains hushed, almost reverent. Conversations are low-key. The loudspeakers, no longer overshadowed, seem to blare. Once again, it has worked.

Suddenly you realize all that could have gone wrong.

Gerard R. DeFranco.