IS REFURBISHMENT RIGHT FOR YOU?

All local governments—from large cities to small villages—are feeling the impact of the rough economic times the country has been experiencing in recent years. Each city agency is fighting for its piece of the budget “pie” to maintain its daily operations and services at a reasonable level. Needless to say, this is a poor time to request funding for a new piece of fire apparatus, even though the need might be completely evident.

As the truck committee or fire chief submits all justification for and the projected cost of the replacement, it is inevitable that the question will be asked about the possibility of refurbishing the old vehicle. Let’s explore the subject of refurbs to see if it is a viable alternative for you.

REFURB VS. NEW

The degree of refurbishment can run the gamut from a fancy paint job and trim work to upgrading the power plant, drivelines, pump, or aerial device or even replacing major components, such as the cab, to bring the unit into full compliance.

Some of the reasons you might consider refurbishing an existing unit as opposed to purchasing a replacement include the following:

- Finances. Obviously, if money is no object, you can consider the outright purchase of a new, custom-built apparatus that fits your needs. Unfortunately, funding is a major consideration for all of us.

- Size. Older apparatus generally are smaller in overall length and height. Many units, especially aerial apparatus, just barely fit in quarters now. Modern apparatus are built larger to accommodate more equipment, larger tanks, and longer aerial devices and to accomplish more functions, such as rescue and haz-mat pumper combinations. To comply with the present axle-weight regulations and provide a safer weight distribution, tandem rear axles often are required, adding considerably to the overall length of the vehicle.

- Weight. Just as modern apparatus have increased in size, the gross vehicle weiglit also has increased substantially. Older fire stations with basements under the apparatus floor capable of supporting the weight of the

- present apparatus might require considerable structural renovation and bracing to hold a modern aerial truck.

- Special apparatus or features. Special apparatus used occasionally, such as tank trucks and lighting units, but nonetheless valuable, could be good candidates for refurbishment. Units with special features that cannot be duplicated, such as a short wheelbase, tight-turning radius, or narrow jack spread, might be invaluable when restored to their original states

EVALUATION

Evaluating your current piece of apparatus is the first step in determining if it is practical to refurbish or replace. Some of the considerations follow:

- Is the present unit adequate to complete the mission now as well as five to 10 years from now? Some areas to examine are pump size, tank size, compartmentation, and aerial ladder length. Are they all adequate for the present and planned response district? Are changing demographics requiring you to address new needs such as paramedic, haz-mat, or foam capabilities on your basic fire suppression unit? Are special considerations, such as air-conditioned cabs in the warmer climates, being addressed? Can these upgrades be incorporated in your original vehicle?

- Are there special requirements for the apparatus—such as limited height, weight, length, or jack spread—that would be difficult or impossible to duplicate on a new unit?

- What is the condition of the drive train? Is the engine reliable and up to power? Is the transmission in need of work? What are the conditions of the driveline, differential, axles, and suspension?

- Are the major components of the apparatus up to par? Can the pump easily pass the annual pump test, or is it showing signs of wear? Has the aerial device been inspected and has it passed nondestructive testing recently? Are the water tank and plumbing still in sound condition?

- How close to compliance with present NFPA standards (1901, Pumper Fire Apparatus; 1902, Initial Attack Fire Apparatus; 1903, Mobile Water Supply Fire Apparatus; and 1904, Aerial Ladder and Elevating Platform Fire Apparatus) will your finished refurb come? Many of the changes in the new standards deal with safety items such as fully enclosed cabs, increased ladder tip load requirements, higher visibility, cab noise abatement, and various interlocks. Are you willing to delay the availability of certain safety features until you purchase a new unit?

- Will critical parts be available when needed? Some manufacturers have gone out of business, making replacement parts scarce. In addition, older apparatus historically have a higher cost of maintenance and operation, and difficulty in obtaining parts can add to apparatus downtime.

- What is the condition of the body and the metal work? They probably have been attacked by rust, the biggest “apparatus killer” in the field today. The manufacturers have addressed this by building with nonrusting material as well as by using improved steel and rustproofing techniques.

As you may have noticed, the most obvious sign of a need for upgrade — rust—was last on the above list. The reason for this is that you must address the reliability and dependability of the engine, driveline, and main operating components before considering upgrading the body and making cosmetic modifications.

DEGREE OF REFURBISHMENT

If you were able to answer yes to most of these questions, you then should decide the degree of refurbishment required. Refurbishments generally fall into three categories:

Repowering. This is rehabilitation of the vehicle’s engine, transmission, driveline, and differential. It could involve rebuilding, if necessary. Or it might include converting from a gasoline engine to a diesel engine or from a clutch and standard transmission to an automatic one. These conversions are quite involved and costly.

Reconditioning. This process usually involves returning a vehicle to its original specifications. It includes body work and refinishing as well as possibly repairing or rebuilding the pump, water tank, plumbing, or aerial device and related systems. Other items that might be reconditioned are brake and suspension components (upgrade or replace), wiring, hoses, lines, tires, and batteries.

Rehabilitation. Repowering and reconditioning are involved here, as is bringing the apparatus up to state-ofthe-art condition. This process includes all of the manufacturer’s updates and improvements, if possible, as well as new components and assemblies. This choice obviously is the most costly of the three options.

ONE DEPARTMENT’S EXPERIENCE

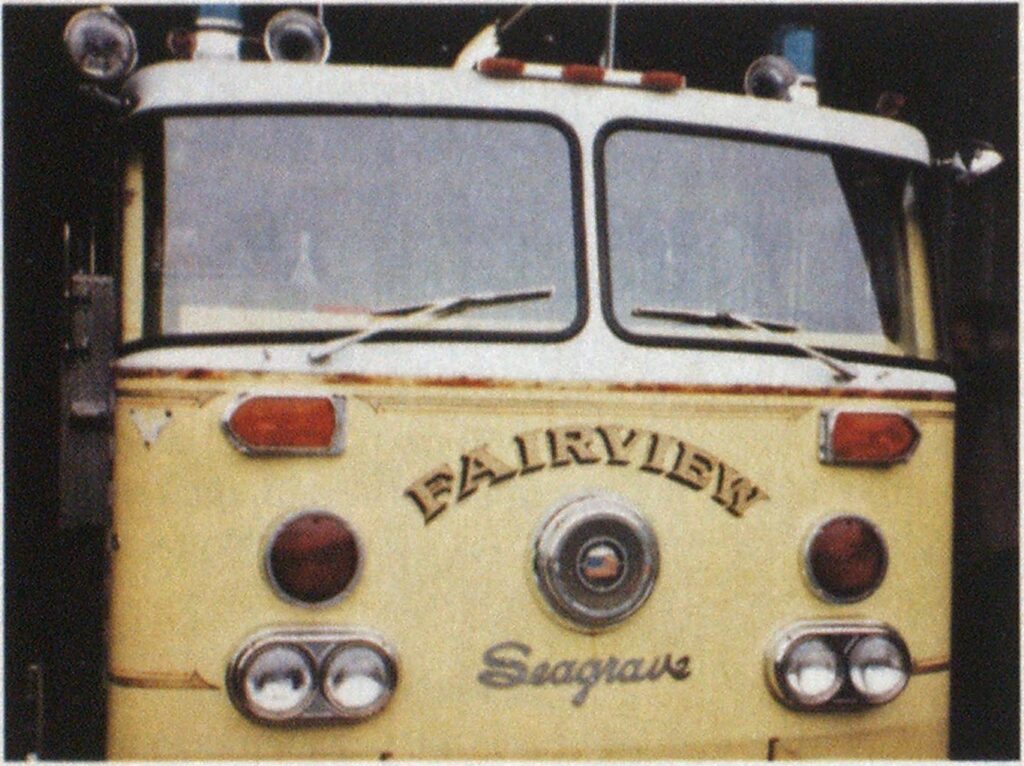

A small community in northern New Jersey started on the road to refurbishment when its 1975 rearmount aerial truck failed a nondestructive test due to physical damage to the ladder. A local apparatus dealer extensively studied the damage and provided an estimate to replace the entire aerial ladder as well as to refurbish the turntable assembly and hydraulic system.

When the truck committee investigated replacement apparatus, the members found that a new unit would cost at least four times the estimated cost to replace the ladder. In addition to the price factor, the fire station at which the unit was housed had an extremely low apparatus door and could not accommodate most new aerials.

The engine, transmission, and chassis were in good condition, since the apparatus had limited use. The body, however, was showing signs of rust and need for attention. The committee decided to proceed with a limited refurbishment.

In addition to the previously mentioned aerial ladder work, the committee specified the following improvements.

- Cab. Strip, sand, repair, and paint the cab interior and exterior. Replace seat cushions and steps.

- Body. Remove parts for painting; replace compartment door latches and weatherstripping; sand, prime, and paint outside; add rubrails; replace diamond plate; and refinish the inside of the compartments.

As work began and components were removed, it was discovered that additional work would be needed. Some compartment panels were badly rusted anti had to be replaced with new fabrications. Other body parts had to be removed, at an additional labor charge, to be repaired and treated for rust in concealed areas.

‘I*o completely finish the truck, the frame rails were sandblasted and painted, and additional SCBA compartments were added, as were more effective warning lights and reflective striping.

The outcome was that for less than SO percent of the cost of a new rig, the life of this previously deadlined unit has been extended for many years, in view of the relatively light service the unit performs.

UNSEEN CONDITIONS

Additional costs, over and above the estimate, are not unusual when undertaking a refurbishment job; they should be expected and planned for. It is the norm to find that additional areas will require attention as major components are removed and hidden deterioration is exposed.

Obviously, when that point is reached, it is too late to turn back; and it would be foolish to ignore the new discovery. You have no alternative other than to allocate additional funds to complete the repair. Some authoritic s advocate including in the original contract a contingency fund from which funds to cover unforeseen needs that arise may be withdrawn; unused money would be returned.

One way to reduce the possibility of having to meet substantial unforeseen costs is to get several estimates from reputable vendors who are accustomed to working on fire apparatus. It would be especially helpful if they have performed similar work on apparatus of the same make and model; they would have additional insight into what can be expected when the components are removed.

This multiple-estimate approach also will assist the committee in drawing up specifications for the work. A more complete picture of the work that needs to be done most likely will emerge if several trained mechanics evaluate the job. In addition, various suggestions and recommendations concerning how the modifications should be undertaken wall allow’ the committee to incorporate the best ideas into the final specs.

BIDDER QUALIFICATIONS

Establishing the qualifications of a bidder on an extensive refurbishment job is every bit as important as establishing them for the purchase of a new vehicle. Specifications should state clearly that you will consider bids only from companies with an established reputation for fire apparatus construction and refurbishment. Require that bidders submit a contact list of other fire departments for whom they have done similar work. Obviously, the references should be checked to verify the quality of workmanship and the bidder’s integrity.

Most commercial truck body shops will not be qualified to deal with all areas of the refurbishment job. Pumps, plumbing, and other apparatus-related items will not receive the proper attention they require. The quality of the finish work and painting normal for commercial customers will not even approach the expectations of the fire service. Save yourself grief by awarding the bid to a reputable fire apparatus repair facility.

Another serious consideration from the point of liability is that the refurbishment or repair of an aerial device be performed or approved by the manufacturer of the unit.

The specifications also should establish a time frame of when the work is to begin and an estimate of when the work will be completed. This information is vital when arranging for substitute fire protection.

Clearly define also the method for picking up and delivering the apparatus, and establish liability criteria for loss, damage, or accident while the apparatus is in the care of the vendor/ bidder.

WARRANTY

Specify that the bidder guarantee that for at least 12 months the refurbished areas of the apparatus will be free of defects in material and workmanship under conditions of normal use and service.