By Eric G. Bachman

Training on recognizing and identifying hazardous materials is, or at least should be, a fundamental part of every firefighter’s knowledge base. Regardless of the tiered training level attained, the use of focused and nonfocused resources is consistent. One of the most elementary of hazardous materials identification skills and competencies is use of the Emergency Response Guidebook (ERG). As we approach distribution of the 2012 edition of the ERG, this is a good time to remind personnel of interpreting and understanding placards.

Annual hazardous material refresher training is required in Occupational Safety and Health Administration (OSHA) 1910.120, Hazardous waste operations and emergency response. To comply with this standard, some firefighters complete boiler-plate programs while others participate in internal company-level training sessions. In both cases, firefighters typically perform research exercises using the ERG to identify products and response guidance based on placard information. This annual repetition gives firefighters confidence in using the ERG. Beyond this basic training, it is necessary to review some of the other intricacies and identification influences pertaining to hazard classifications and placards.

HAZARD CLASSES

In accordance with 49 Code of Federal Regulations Part 172, Hazardous Materials Table, Special Provisions, Hazardous Materials Communications, Emergency Response Information, Training Requirements, And Security Plans, there are nine hazard classes. Reciting them from memory, however, is not as important as readily recognizing them at an incident. There are many mnemonics used to recollect the hazard classes (like Every Good Lieutenant’s First Standard Operating Procedure Really Can Matter) Regardless of whether the mnemonic helps, review of the hazard classes is important. Class 1 represents Explosives. This category is has six subdivisions to distinguish detonation characteristics. The lower the subdivision class number, the higher its danger–for example, explosives division 1.1 is characterized with a mass-explosion hazard. Conversely, explosives division 1.6 indicates an extremely insensitive article.

Class 2 signifies Gases. It has three subdivisions that distinguish specific physical hazards. Division 2.1 placards represent flammable gases like acetylene and propane. Division 2.2 represents nonflammable gases like nitrogen and carbon dioxide. Use caution when interpreting these placards, especially with regard to nonflammable placarded products. Personnel often view this placard as nonthreatening. In some cases, though, there is more than meets the eye. Anhydrous ammonia, for example, is placarded nonflammable (photo 1). When reviewing its physical characteristics, it has a flammable range of between 16 percent [lower explosive limit (LEL] and 25 percent [upper explosive limit (UEL)]. When I teach hazardous material training to first responders, I facilitate a discussion as to why, if anhydrous ammonia has a flammable range, is it placarded nonflammable? No one in the awareness or operations programs has ever answered correctly. The reason is based on the definition of a flammable gas. A flammable gas is one that, at ambient temperature and pressure, forms a flammable mixture with air at a concentration of 12 percent (LEL) or less by volume. Therefore, because the LEL of anhydrous ammonia is higher than 12 percent, it is classified as nonflammable. Division 2.3 represents poisonous gases like chlorine and phosgene. In the ERG, the terms “toxic” and “poisonous” are used synonymously.

(1) Anhydrous ammonia is placarded non-flammable.

(2) A Corrosive placard features graphics to represent destruction to skin tissue and corrosion to steel.

Class 3 includes flammable and combustible Liquids. According to the ERG, a flammable liquid has a flash point of 141ºF or lower, like gasoline. It defines a combustible liquid, like diesel fuel, as one having a flash point greater than 141ºF. A concern with this class is temperature sensitivities in comparison to the atmospheric conditions over the course of an incident. A product with a low flash point may not be as affected by atmospheric conditions during the typically colder early-morning hour, but rising temperatures after sunrise could cause product boiling and increased internal vapor pressures. Depending on the severity of the damage to the container, this could be a catalyst for early container failure.

Class 4 represents Flammable Solids, This class provides three subdivisions. Division 4.1 represents solids likely to ignite by friction and ignite readily, resulting is vigorous and persistent burning. Examples include aluminum powder and zirconium powder. Division 4.2 includes pyrophoric substances that, even without an external ignition source, can ignite after coming in contact with air. An example of this is iron oxide. Division 4.3 includes products that become spontaneously flammable or give off flammable or toxic gas when contacted by water. Examples include sodium, which explodes on contact with water, and calcium carbide, which produces acetylene gas.

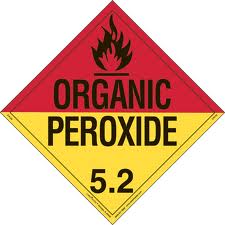

Class 5 products are classified as Oxidizers, products that yield oxygen in a fire, causing more intense flames. This class has two divisions. Division 5.1 is an oxidizing agent, such as potassium permanganate, often used in wastewater treatment. Division 5.2 represents organic peroxides. Organic peroxides pose fire and explosion hazards. An example is methyl ethyl ketone peroxide (also known as 2-butanone peroxide, ethyl methyl ketone peroxide, or MEKP). Organic peroxides may also be toxic or corrosive.

Class 6 represents Poisons and has two divisions. Division 6.1 represents liquids and solids (slurries and powders, too) known or presumed to cause death through skin absorption, ingestion, or inhalation. Examples include cyanide solids and solutions. Division 6.2 includes infectious micro-organisms or toxins that may cause human or animal diseases.

Class 7 represents Radioactive products. These materials spontaneously emit ionizing radiation. Although there are no radioactive placard subdivisions, there are specific labeling criteria for packages that present variations from the classic radioactive placard.

Class 8 includes Corrosives. A corrosive is any liquid or solid that causes destruction of skin or a liquid that has a severe corrosion rate on steel. Common corrosives include sulfuric, hydrochloric, and nitric acid.

Class 9 is Miscellaneous materials that do not meet the definition of hazard classes 1 through 8. They do, however, present a hazard during transportation or have anesthetic, noxious properties. Examples of Class 9 materials include molten sulfur and dry ice.

PLACARD DESIGN

Placards, according to 49 CFR section 172.519 (c), “must measure 10.8 inches on each side and have a solid inner border approximately 0.5 inches from each edge.(2)” Beyond the size, placards generally present four elements that, collectively, must be evaluated to clarify the chemical classification and physical state. One of the most observable elements is the background color. In many cases, the background color indicates a specific hazard class. When firefighters are queried on background colors, they are consistent with their response to orange (explosives), red (flammable), green (nonflammable) and blue (dangerous when wet). But when questioned on some of the variations, such as white over black and atypical examples such as red and white vertical stripes, they hesitate with their responses.

Background color is just one clue that should be used to corroborate other placard elements. Color alone, however, may not be a true indicator of the hazard class. Colors can fade and not be representative of the commodity being transported. In addition, some people are color blind and are unable to see or perceive color differences.

A second placard element is the graphic. Each hazard class has its own associated graphic that is placed in the top point of the placard. Some are hazard class-centric, like the compressed gas cylinder graphic on a Class 2 nonflammable gas placard. Others may be shared, such as a shadowed flame that can be affixed to the Class 3 liquid and Class 4 solid placards. The shadowed flame is indicative of a fire hazard. The corrosive placard presents two graphics to correspond to the skin destruction and corrosion of steel (see photo 2). Others, such as the radioactive trefoil, are recognized outside of the transportation placard system and by people outside of the emergency services. A third element is the center section of a placard, which can contain the product identification number or the generic hazard class. The four-digit product identification number is cross-referenced in the ERG.

The fourth element is the hazard class number in the bottom point of the placard. This element is perhaps the most important, especially if the four-digit product identification number is not printed and if the ERG is not readily available. This number distinguishes the hazard class and indicates the material’s state of matter. Its importance is realized when interpreting similar color background products. Although a placard with a white background typically indicates a poison, a number “2” in the bottom point distinguishes it as a gas. A placard with a white background that has the number “6” in the bottom point indicates that the material is a poison and also that the product is a solid, liquid, powder, or slurry. From an operational standpoint, this is important to recognize early for strategy and public protective action considerations. A release of a poison (a material with the number “6” in the bottom placard point) can be confined when released as opposed to the uncontrollability of a gas release. The same holds true for flammable liquid placards (photo 3) and flammable gas placards (photo 4). At first glance, both placards look alike; however, despite the similarity in the placard elements, the bottom point numbers yield important information: the “2” indicates a gas and the “3” a liquid.

(3) A flammable liquid placard is similar to that of a flammable gas. The liquid state is distinguished by the number “3” at the bottom point.

(4) A flammable gas is similar to that of a flammable liquid. The gaseous state is distinguished by the number “2” at the bottom point

PLACARD THRESHOLDS

The hazard classes and their subdivisions are categorized, in accordance with 49 CFR section 172.504(e), into “Table 1” and “Table 2.” “Any bulk packaging, freight container, unit load device, transport vehicle or rail car containing any quantity of material listed in Table 1 must be placarded.” (1) The hazard classes that apply to this ruling include explosives divisions 1.1, 1.2, 1.3; poison gas division 2.3; dangerous when wet division 4.3; organic peroxide division 5.2; and radioactive.

Placards for the remaining hazard classes in Table 2 apply when “the aggregate gross weight of all hazardous materials in non-bulk packages” (1) meets or exceeds 1,001 pounds. Because of this variable, a transport vessel may not present a placard but nonetheless may contain hazardous cargo.

(5) A truck presenting a Dangerous placard.

DANGEROUS PLACARD

A less product-specific but commonly posted placard is “Dangerous” (photo 5). This placard is allowed when two or more categories of hazardous materials require separate placards as specified in Table 2. “However, when 2,205 pounds or more of one category of materials is loaded at one loading facility,” the Table 2-specified placard must be applied (1).

ORGANIC PEROXIDE PLACARD

The red-over-yellow organic peroxide placard (figure 1) was first listed in the transportation regulations in 2006. The new design allows responders to readily distinguish peroxides from oxidizers. The regulations established implementation parameters for certain transportation modes for mandatory use of the placard. For transportation by rail, vessel or aircraft, use of the new organic peroxide placard was effective January 1, 2011. For transportation by highway, it is mandated on January 1, 2014. This does not mean that you will not see the newer 5.2 placard on the road before 2014. It means that transporters have until that date to transition to the new placard.

Figure 1: Organic Peroxide Placard, Source: prweb.com

PLACARD PLACEMENT

Emergency responders generally know that the placards are posted on four sides of the transportation vehicle. 49 CFR section 172.516 addresses the visibility and display of placards. Specifically, it states that “each placard on a motor vehicle and each placard on a rail car must be clearly visible from the direction it faces, except from the direction of another transport vehicle or rail car to which the motor vehicle or rail car is coupled (2).” For a motor vehicle, a placard “may be on the front of the truck tractor instead of or in addition to the placarding on the front of the cargo body to which the truck-tractor is attached (Section 172.516 (b) – (2).”

ACCURACY

No system is perfect, placards included. Beyond the legislative requirements, there are other circumstances and influences that can affect first responder interpretation and accuracy involving them. Packages, containers, and transport vehicles can be improperly placarded. Transporters may overlook changing placards on frequently used vehicles, and you cannot discount the intentional omission of placards for shipments that are prohibited from being transported over certain roadways.

Vandalism is another consideration. Some placard assemblies can be manipulated to change their information. Trailers at truck stops or job sites are prone to vandalism. At a transportation incident, it is just as important to conduct a 360° size-up of a transport vehicle as it is of a fixed facility. This enables the first responder to locate directional placed placards to corroborate information.

Preplanning is a universal practice for all hazards, not just for the built environment. Staff should constantly observe truck logistics facilities and construction sites to develop situational awareness. Some sites will changes daily, further reinforcing the need for consistent preincident situational awareness. Hazardous commodities may be trailer-stored at job sites (photo 6) in quantities requiring a placard. Take note of the placards, and identify the contents. It is extremely important to maintain rapport with the construction manager of all aspects of the project and the site.

(6) A trailer at a construction site with a flammable gas placard.

As an example, when a hotel in my jurisdiction was undergoing a significant renovation project, construction trailers were staged throughout the parking lot. During one after-hour windshield survey to note project progress, I noticed one trailer presented a radioactive placard that I had not noticed before. I contacted the project manager to ascertain its contents. In fact, there were no radioactive products on the trailer. Someone had changed the placards. Similarly, trailers that sit for periods of time also are prone to placard tampering. Photo 7 shows a trailer that presents an oxidizer placard on one trailer side. The front placard bracket is not displaying a hazard class. Photo 8 shows another trailer that presents a radioactive placard on the side and no hazard class on the front. If you are not diligent in preplanning elements outside of the built environment in your district, you may not know what is normal or abnormal.

(7) This trailer is placarded only on one side as an oxidizer. Note that it is not placarded on the front.

(8)The placard on the side of the trailer, used for general storage at a facility, has been tampered with, presenting a radioactive placard.

(9) A broken placard bracket allows a portion of the placard to flap.

Another consideration is unmaintained, broken, or damaged placards. Universal placards are equipped with clips that hold the desired hazard class placard in place. They are susceptible to damage which could cause flapping placard sections (photo 9). Direct and indirect impact, scoring, or other mechanical influence could cause a placard assembly to fall off. Flame impingement, too, could influence placard integrity.

INTERPRETATION

As mentioned above, one of the placard elements is the center field that may contain the hazard class name or the identification number. A commodity-specific standalone placard with the identification number printed may be easily read. However, a universal (flip file) placard that allows for the exchange of identification numbers may prove challenging. The pivot point of the identification number flap can influence the readability. Numbers like 0, 3, 5, 8, and 9 can be misinterpreted. Evaluating a placard from a distance will further influence interpretation, even with binoculars (photo 10).

(10) Interchangeable numbers on some placards may be difficult to interpret, especially from a distance.

The purpose of this article was to illustrate common misunderstandings and issues related to placard interpretation. There are other placard aspects not provided in this article. For more information, visit the U.S Department of Transportation Pipeline and Hazardous Materials Safety Administration Web site at http://phmsa.dot.gov/hazmat .

***

Recognition and identification of hazardous materials is a basic competency. Emergency responders must understand the fundamental elements of placards and as well as their limitations. The issue of placards may seem black and white, so to speak, but there are many caveats and variables that affect accurate evaluation. Personnel must be cautious when interpreting the clues an incident presents. For a potential hazardous materials incident, product verification is necessary for initiation of proper strategies and tactics. Things cannot always be taken at face value. The need to be cautious and safe at a potential hazardous materials incident goes without saying. But it is also important to be thorough.

Eric G. Bachman, CFPS, a 29-year-veteran of the fire service, is former fire chief of the Eden Volunteer Fire/Rescue Department in Lancaster County, Pennsylvania. He is the hazardous materials administrator for the County of Lancaster Emergency Management Agency and serves on the local emergency planning committee of Lancaster County. He is registered with the National Board on Fire Service Professional Qualifications as a fire officer IV, fire instructor III, hazardous materials technician, and hazardous materials incident commander. He has an associate degree in fire science and earned professional certification in emergency management through the state of Pennsylvania. He is also a volunteer firefighter with the West Hempfield (PA) Fire & Rescue Company.