By ANTHONY ROWETT JR.

Is the gated wye a part of your high-rise hose pack? If it is, reevaluate your standpipe operation equipment selection and your overall standpipe operation tactics. The last thing you want to happen is to get 50, 75, or 100 feet or more down a hallway just to have an unexpected reduction in your flow rate or, worse, a complete loss of water. This will happen when the second hoseline is connected to the other discharge outlet of the gated wye and charged or the valve handle controlling the outlet of the gated wye to which your hoseline is connected is accidentally closed.

Preplanning: Include the Hose Stretch

When the second hoseline is charged and placed into operation, the initial hoseline will experience a reduction in its flow rate as the gated wye divides the available water supply between the two hoselines. The National Fire Protection Association (NFPA) addresses the use of gated wyes during standpipe operations in NFPA 13E, Recommended Practice for Fire Department Operations in Properties Protected by Sprinkler and Standpipe Systems, by stating, “Attaching a 2½-inch [63.5 millimeters (mm)] × 2½-inch gated wye to a standpipe outlet to allow the connection of two 2½-inch or larger diameter hoselines is not always a recommended practice because 2½-inch standpipe outlets are required to flow only 250 gallons per minute [gpm] (946L/m) and might not support flowing two handlines simultaneously. Pressure reducing valves (PRV) connected to 2½-inch standpipe outlets are generally sized for 250 to 400 gpm (1,514 L/m) and should generally not provide adequate flow for two large-diameter hoselines. Initial actions should be to connect a single large-diameter hoseline to each standpipe connection. Additional hoselines can be connected to standpipe hose connections on lower floors.”

Standpipe systems are already prone to low-pressure situations that can result in reduced flow rates without firefighters introducing additional factors they can add to the system such as the gated wye. Add the presence of an improperly set factory preset or a field-adjustable PRV coupled with a firefighter who does not possess the knowledge or equipment to adjust the PRV, and the stage is set for disaster. Add to this equation a gated wye that will divide the already reduced flow rate between two hoselines rather than simply supplying a single hoseline as the standpipe system is designed to do, and problems can occur.

There is an additional concern with gated wye use during standpipe operations. When we use a gated wye as part of a standpipe attack package, it is typically connected to the standpipe system hose outlet valve by a short section of 2½- or three-inch hoseline, commonly referred to as a “pigtail” or “trunk line.” The pigtail/trunk line positions the gated wye on the floor rather than in the air at the level of the standpipe system hose outlet valve. The problem with positioning the gated wye on the floor is that the valves can be accidentally closed as firefighters move past the gated wye in their ascent to the fire floor.

Our Flow Tests

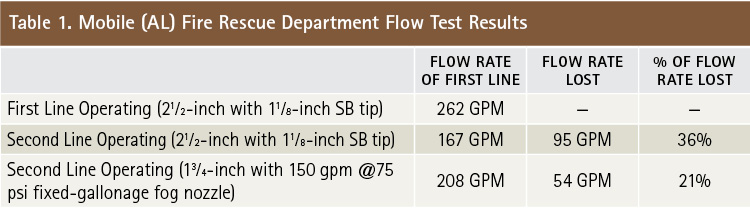

To determine the effect of using a gated wye during a standpipe operation, the Mobile (AL) Fire Rescue Department performed two sets of flow tests (Table 1) using a portable flow meter. We positioned the flow meter within the stretch of the hoseline that was being used as the initial hoseline. For these flow tests, we used a 50-foot length of 2½-inch hoseline from the outlet to a 2½- × 2½-inch gated wye. For the first series of flow tests, we connected three 50-foot lengths (150 feet) of 2½-inch hoseline with a smooth bore nozzle and a 1-inch tip to each of the gated wye’s discharge outlets. Although using a 2½-inch hoseline is the recommended practice, for our second series of flow tests, we did not use another 2½-inch as the second hoseline from the gated wye. Instead, we used three 50-foot lengths of 1¾-inch hoseline (150 feet) with a 150-gpm @ 75-pounds-per-square-inch (psi) fixed-gallonage fog nozzle; this is still a common tactic for many departments around the country.

The results of our flow tests showed that using a gated wye during a standpipe operation will result in a significant reduction in the flow rate of the initial hoseline after the second hoseline is connected to the gated wye, is charged, and begins flowing and operating. It is important to note that if we use a gated wye during a standpipe operation, communication is vital. Otherwise, the reduction in the flow rate of the initial hoseline that occurs when the second hoseline begins operation will be unexpected and occur once the initial hoseline has been advanced a significant distance down a hallway or has made it to the fire area.

In both series of flow tests, the initial hoseline was flowing 262 gpm. The issue of a reduced flow rate was prominent in both series of flow tests. When the second hoseline was a 2½-inch with a 1-inch smooth bore tip and both lines were flowing, the flow rate of the initial hoseline fell to 167 gpm, a 95-gpm (36 percent) reduction in the flow rate. When the second hoseline was a 1¾-inch with a 150-gpm @ 75-psi fixed-gallonage combination fog nozzle and both lines were flowing, the flow rate of the initial hoseline was reduced to 208 gpm, a 54-gpm (21 percent) reduction in the flow rate.

In addition to the flow rate fluctuations that will occur in the initial hoseline when the second hoseline is connected to the gated wye, is charged, and begins flowing and operating, there will also be pressure fluctuations in the hoseline. Every time the nozzle of one hoseline is opened or closed, the flow rate and pressure of the other hoseline will either increase or decrease. When one of the hoselines experiences an unexpected, rapid increase in pressure after the other hoseline’s nozzle is shut down, this pressure increase will create an unsafe, unexpected, and rapid increase in nozzle reaction force that the nozzle team must now manage. As stated above, communication is vital when gated wyes are used because of the fluctuations in both flow rates and nozzle reaction forces when the nozzles of either hoseline are opened or closed.

Best Practices

Some firefighters consider there to be one exemption to the “no gated wyes for standpipe operations” rule. Many firefighters use a gated wye on the second hoseline when just one hoseline is connected to a standpipe system hose outlet valve, which is the recommended practice. When performed in this manner, the initial hoseline is connected to a standpipe outlet valve on the floor below the fire floor while the second hoseline is connected to a standpipe outlet valve two floors below the fire floor. When the second hoseline is connected to the standpipe system by an outlet located two floors below the fire floor, a length of 2½-inch hoseline with a gated wye is connected to the standpipe system outlet and stretched up the stairs to the floor below the fire floor. The gated wye is then positioned near the standpipe outlet valve to which the initial hoseline is connected.

Using a gated wye during this operation frees a firefighter to operate the hoseline. When operating from a standpipe system, a firefighter must remain at the outlet and control the hoseline for proper pressurization and flow. By positioning the second hoseline’s gated wye on the floor below the fire floor, the firefighter controlling the initial hoseline’s outlet can also control the second hoseline’s gated wye; this allows an additional firefighter to operate on the hoseline, and a firefighter will not have to stay at the outlet. The firefighter now controlling the initial hoseline’s outlet and the second hoseline’s gated wye can, in addition to controlling proper pressurization of the two hoselines, ensure no additional hoselines are connected to the gated wye that is supplying the second hoseline, ensuring that neither hoseline experiences an unexpected reduction in its flow rate because of another company connecting to an open outlet on a gated wye and charging their hoseline from the gated wye.

Although using the gated wye in this manner during standpipe operations eliminates the problem of dividing the water supply from a single standpipe system hose outlet valve between two hoselines, it does not address the issue of the gated wye valves being accidentally closed by passing firefighters. It is better to perform this operation in the same manner but replace the gated wye with a gate valve. Here, the second hoseline is connected to a standpipe outlet valve two floors below the fire floor and a gate valve (rather than a gated wye) is placed in operation on the hoseline and positioned on the floor below the fire floor. Now, the gate valve cannot be accidentally closed as easily by passing firefighters in the same manner as the gated wye.

Using a gate valve rather than a gated wye also allows for greater control in fine tuning the pressure of the hoseline. Positioning a gate valve (not a gated wye) in the second hoseline on the floor below the fire is the recommended practice for the second hoseline.

Being Prepared

For most firefighters, standpipe system operations are considered high-risk/low-frequency incidents. Although many firefighters have little experience operating from a standpipe system (other than, perhaps, the fire department’s training tower), standpipe systems are not likely to provide optimal working conditions. When firefighters operate from a standpipe system, they should expect low pressures and debris from the system; expect these problems from the onset of the operation while avoiding adding more to the operational equation, such as gated wyes.

Communication is vital to the success of any fireground operation; this is especially true of standpipe operations. Using gated wyes during standpipe operations further increases the importance of communication. You must notify the firefighters on the initial hoseline before placing a second hoseline into operation; this allows them to prepare for the reduction in the flow rate of their hoseline. As such, any time firefighters of either hoseline are about to open or close their nozzle, you must notify the firefighters on the other hoseline so they can prepare for the increase in flow rate and nozzle reaction forces that will occur in their hoseline.

ANTHONY ROWETT JR. is a captain with the Mobile (AL) Fire Rescue Department. He was previously a firefighter with the Ogdensburg (NJ) Fire Department. He has an AAS degree in fire science technology, a B.S. in fire science, and an M.S. in emergency services management. He is a graduate of the Alabama Smoke Diver course and the owner of Port City Fire Training, LLC. He is an instructor at Gulf Coast Emergency Response Academy. He is a contributing author to fire service publications and has instructed at fire conferences and individual fire departments. He has served as a lead H.O.T engine company operations instructor and is a co-host on the “Generation Engine“ podcast for Fire Engineering.