FORCIBLE ENTRY

FIREFIGHTING BASICS

Part 3

With the rising crime rate, security has become a major problem for storekeepers—and for firefighters who must gain entry in the event of a fire.

Sliding security gates (scissor gates) were the commonly used device to withhold intruders from entering commercial occupancies during non-business hours. However, during the early 1960s’ and 1970s’ urban unrest, first on the west coast, then on the east coast, these gates provided many “holding points” for various homemade chain and hook devices. The hook was attached to the scissor gate and the chain end was wrapped around the rear of a vehicle. The storefront protection was then pulled out of the way and the looter gained quick and easy access to the building.

In answer to the looting problem in the commercial urban areas, rolldown security metal doors replaced scissor gates. Corrugated, interlocking steel slats, three-inches wide of 20-gauge steel span the opening to be protected. These roll-down doors operate from a counterbalanced, covered winding drum, much like household window shades. The face of the rolldown door (curtain) rides in steel channels on each side of the span. These channels (guides) usually provide the fastening areas for the various types of bolts and padlocks that secure the door.

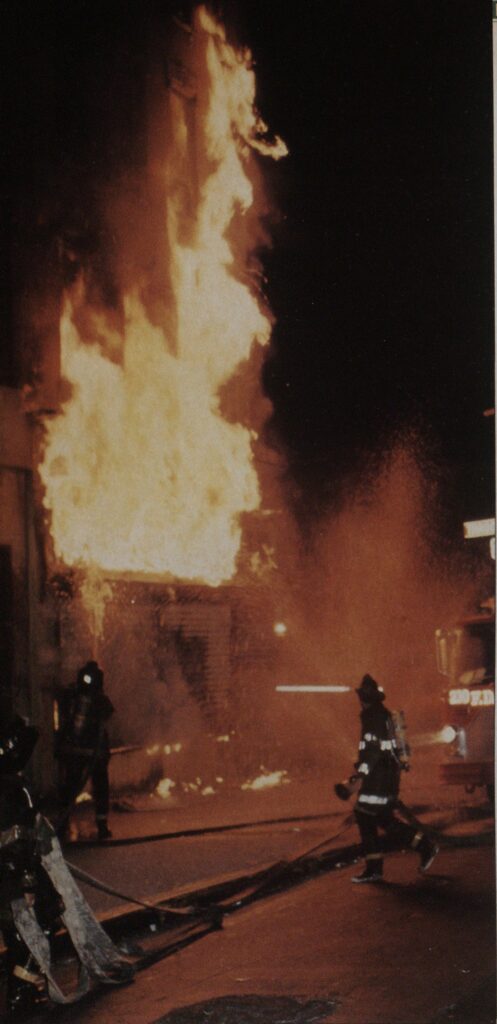

FIRE CONDITIONS AND CONSIDERATIONS WITH HIGH SECURITY DOORS

The installation of roll-down metal doors on storefronts did indeed solve the security problem posed by the sliding gates. However, when a building that is protected by this high security becomes a fire occupancy, these doors in the closed position can greatly intensify our fire problems, immensely affect our attack strategy, and definitely influence our tactics.

Photo by By Bob Pressler

Photo by Tom Brennan

Photo by Bob Pressler

Photo by Bob Pressler

- Fire conditions in these tightly sealed buildings are usually severe. Being aware of what to expect can help in pre-planning strategies and tactics.

- The fire will be delayed in its discovery. Since the rolldown door blocks the vision of occasional passersby during nonbusiness hours, fire often reaches such intensities that it “pushes” or burns its way to the outside. The smoke travels through cracked or otherwise failed glass, and the interior pressure further pushes this smoke or other combustion products through the smallest channels to the outside. The heavier than normal smoke condition causes an additional delay in the fire attack because of the inability of the fire department to rapidly pinpoint the seat of the fire. This is especially true in the case of single-story, row stores (taxpayers).

- The fire will be more intense on arrival. The fire, when located behind these security doors, will gain in intensity because of discovery and access delays. Additional time is needed to manipulate the locking devices and to roll up or otherwise remove the doors. This time factor is increased even if we have the key(s).

- Backdraft or smoke explosion conditions will become more common as the fire is not able to vent itself. The increased “tightness” of the secure building, coupled with delayed discovery, will allow the fire to move through its stages to the fourth or smoldering stage. It is at this stage that the high pressure, high temperatures, and heavy amounts of explosive gases (mostly carbon monoxide) combine to form the condition that awaits horizontal ventilation to result in a backdraft or a later smoke explosion.

- A greater horizontal and vertical spread (both up and down) of heat, smoke, and flame is probable. A large portion of the occupancy (if not all) will be either directly involved in fire or at dangerously elevated temperatures (flashover conditions). Because access to the occupancy is delayed, heat and flame has a chance to penetrate horizontal separations within the fire occupancy that otherwise would have compartmentized the occupancy causing additional and otherwise abnormal fire extension.

- A delay in nearly all fire department operations will result from the extra time necessary to manipulate these security doors.

- Delay in an aggressive interior attack.

- Delay in the ability to adequately protect occupants and searching firefighters above the fire. Our ability to gain entry and place water between the fire and its most severe exposure (life) is delayed.

- Exposure protection must be expanded and made more urgent. These security doors will also delay our opening and examining adjoining occupancies for fire spread, causing us to give up more of the structure and to increase our manpower needs. Indeed, failure to anticipate for firefighting delays will cause us to play catch up throughout the operation.

- These roll-down metal doors also:

- Signal the need for additional manpower and equipment immediately. Since forcible entry problems will occupy most of the original response, other areas of responsibility will demand additional manpower. Prompt vertical ventilation will be delayed because the equipment necessary for venting (power saws, for example) may be needed for forcing entry. Also, once access has been gained, the possibility of severe fire intensity and extension will require additional handlines.

- Hinder or prevent our access to cellars. These metal doors are usually installed some distance out from the exterior face of the building line. Therefore, when closed, they prevent the upward swing and opening of sidewalk cellar entrance doors.

- Are sometimes installed without regard to the connections for automatic suppression systems (standpipe and sprinkler Siamese connections), covering over and blocking fire department access to these outlets.

- May have been installed with careless planning or lack of supervision, closing off exterior access doors to the occupancies above the store that the door protects.

Prior to the increased “wrapping” of these commercial occupancies, backdraft had become a rare phenomenon. Lighter construction and more fragile glass allowed the fire to breathe and self-vent prior to being able to reach ideal backdraft conditions (evolution of large amounts of carbon monoxide plus continually elevating temperatures with the consumption of oxygen to the point that active flaming ceases). In fact, most of the “experienced” backdrafts are, in reality, the much slower flashover or rollover.

Failure of partitions between adjacent occupancies is not only a possibility but may go undetected for a longer time because of the necessity to force the security doors in order to examine these exposures also.

More important and more common horizontal fire extension in one-story commercial occupancies is via the common roof space or cockloft. In fact, this condition is almost guaranteed in single-story, attached, commercial occupancies that are protected by roll-down doors and which experience a fire during non-business hours.

Vertical extension of the products of combustion is greater both above and below the fire. The smoke, heat, and fire extension conditions (because of the fire’s inability to vent itself horizontally) will be greater. The life exposure to the occupants above the fire floor will be more intense. Search operations will be extremely difficult and dangerous. Conditions below the fire will be abnormal. Heat and products of combustion will make a normally safer area untenable.

One can readily see that a quick and efficient size-up of the forcible entry problem posed by these doors will relate directly to the efficiency quotient of the fire department operations.

We have four options available to us at fires involving occupancies protected by these high security devices:

Photo by Bob Athanas

- Successfully manipulate the locking devices and open the door as does the owner during his normal entry.

- Cut the door itself, thereby destroying its integrity and literally dismantling it.

- Pull the complete assembly from the facade of the structure.This method may be necessary if there was explosion damage prior to our arrival. In some cases, this may be our only alternative.

- Seek an alternate means of entry. This option is often impractical because alternate entry paths are usually even more heavily secured in occupancies protected by these devices—if these paths even still exist at all.

ROLL-DOWN METAL DOOR CONSTRUCTION

Understanding the construction of roll-down metal doors is the key to our ability to manipulate these security devices and gain access to the occupancy that they protect.

- The winding drum and one guide rail or track is installed first.

- The steel angle iron bottom bar is installed or connected to the base of the door by affixing it to the last slat.

- A second metal track is now installed on the opposite side of the fitted slats. These steel guides also provide the strength for the locking devices.

One-by-one, the interlocking 3-inch, corrugated steel slats that form the curtain from the drum to the base of the opening are assembled and laid in the installed guide.

Now the door may ride up and down in its two tracks or guides. There are three methods of raising and lowering these doors depending on the installation:

- Manually—lifted by hand and raised onto its counterbalanced roller located in the winding drum.

- Mechanically—raised by chain hoist, hand operated.

- Electrically—raised by a motor driven hoist that is activated by a key located somewhere in the facade of the structure.

All three types of roll-down door assemblies are secured by metal pins inserted through the curtain slat and through matching holes in the guide rails (see illustration). These removable pins are common devices and are held in place by padlocks of varying strengths.

Type I, manually operated doors

Manual doors are the least costly of all roll-down metal door installations. Usually located on smaller, “mom and pop” type stores, their widths are not generally excessive. However, on some occupancies, more than one manual door installation may be found to cover larger storefronts.

Manual roll-down metal doors are easily recognizable by the absence of any hoisting mechanism and by the raising handle(s) affixed to the bottom bar.

Photo by Bob Pressler

Photo by Tom Brennan

Photo by Paul McFadden

Photo by Paul McFadden

Manually operated doors usually have two lock assembly locations, but as many as six may be found on each door.

To operate these doors, the store owner removes the locks showing from the outside and pulls the door up onto its spring assisted roller, using the handle attached to the bottom bar.

NOTE: On multiple installations of roll-down security doors, the door that gives the owner access to the occupancy (the door we want to force first) will be locked last. It may be the narrowest door that reaches the sidewalk, but it will always have exterior accessible lock assemblies affixed to it. Additional doors covering display windows or loading areas may be lowered and secured from inside before the owner leaves the occupancy. This lockup method is done for two reasons:

- It presents no fastening devices to the outside to be manipulated for criminal reasons.

- Those doors may be secured by cheaper, less complicated devices, i.e., sliding bolts, latches, pins, etc.

Type II, mechanically operated doors

Mechanical doors are the most frequently installed roll-down door assemblies. They operate by a common chain hoist mechanism located in a metal box-like enclosure found at the side of the winding drum. Once the chain is exposed and the local assemblies removed, the door can be raised.

However, remember that we are dealing with high security, and the chain is not readily accessible. It is usually located behind a pivoting angle-iron guard which, in turn, is secured by one or (in most cases) two padlocks. These are in addition to the door fastening devices. The chain, however, is visible to the firefighter as it leaves its winding wheel and enters the protective angle-iron guard channel.

Mechanical doors have a heavier bottom bar and, in most cases, have slide locking devices welded to it. These devices have two positions:

- Unlocked—where the slide locking device is against its stop and padlocked in the open position.

- Locked — where the slide locking device is slid through an opening in the base of the door guides on each side. The padlock is inserted through the lock stop and the hole in the slide device. Two or more additional locking points are usually found in these doors, similar to the pin and eye assemblies on manual type doors.

To open the mechanical rolldown door, the owner removes all locking devices (as many as eight), then swings open the angle iron covering the chain, removes it from the hold-down pin, and hoists the door open onto the drum.

Photo by Tom Brennan

NOTE: For his convenience, the owner may padlock only the door fastening devices and simply latch the slide locking devices. In this case, the firefighter may think the door is openable once all the padlocks are removed, but the slide latches will hold the door secure. Always look for these slide latches and assure their open position before attempting to manipulate the chain hoist device.

The slide latch may have a very expensive locking device affixed to either side. The shackle (bow) is unexposed and the device is “nestled” against the sidewalk and the base of the door. All methods of forcing this lock (except by means of the acetylene torch) will prove ineffective and too time consuming.

In other words, attacking this lock is useless. The door itself must be cut. (In our size-up, the presence of these locking devices saves us decision making time since our only choice is to use the power saw to destroy the door’s integrity.)

If all door-holding devices are removed and the chain protecting device cannot be opened, we may cut both sides of the exposed chain as it is seen going around the pulley at the top of the door. This should remove the locking ability of the chain and hoist assembly and the door may be lifted manually.

NOTE: This door is much heavier than the manual type installation and will require two or three people to raise it. The door should be held open by hooks or other propping devices once it’s opened, as some of these doors may fall back down and trap firefighters operating inside.

The chain device may be located in some recess in the building’s facade, obscured from view by a hinged door assembly that is easily pried open. Locating the chain assembly that may be on the outside of the building and noting its direction will give away the “hiding place” of the chain.

On large occupancies, only the last door closed may have exterior accessible locking devices (as mentioned previously). The owner may secure his whole facade by interior chain hoist assemblies from inside and then exit the premises from a smaller, obscure door at a remote location around the building’s perimeter. Conditions like these “special cases” must be found by pre-planning and/or inspections. The urgency of the fire scene does not allow for alternative, particular, or unique security methods that have not been discovered before the emergency.

Type III, electrically operated doors

Electrical doors are the most expensive and the least frequently found. They are normally raised and lowered (as the name implies) by an electric motor which is connected by clutch and drive assemblies to the hoisting mechanism. The assembly is recognizable by the extremely large enclosure located to the side of the winding drum and the presence of a key switch in the wall or facade.

The owner removes the door’s padlocks and slide lock mechanisms (just as with mechanical doors) and activates the operator (motor) by a key switch located on either side of the door. This key switch may be in a heavy metal security box.

Thankfully for us, the electrical roll-down door is provided with a manual, fail-safe mechanism. In the event of an electrical failure or the loss of a key, the owner can gain access to the motor housing through a removable plate held in place by a few self-tapping screws.

Inside the housing is a clutch assembly and chain. The motor is disengaged from the hoist by a lever or rope (cable) that is dropped with the chain hoist. Pulling down on the cable disengages the motor, and simultaneously pulling the chain around the pulley will open the door—the locking devices first removed, of course.

Photo by Paul McFadden

We may force entry into this occupancy by removing the locking devices and operating the clutch hoist mechanism just as the owner would do. If the key activated mechanism is exposed, pulling the cylinder will expose two wires. Shorting the wires may activate the power to the winding drum. It doesn’t work in all cases, but it’s worth a try.

If the above methods fail, we can cut the “bicycle” roller chain, freeing the drum from all hoisting mechanisms. This, in effect, creates a manually operated (Type I) door, which can then be raised by two or three firefighters. Remember, the door is heavy and must be held open by propping devices.

FORCING ENTRY

Padlocks

As mentioned in our previous forcible entry article (FIRE ENGINEERING, March 1985), there are two general types of padlocks (regular and heavy-duty) that should be attacked at their weakest point (either the staple, chain, shackle, or tumbler). However, when applied to roll-down doors, special situations can arise with padlocks.

- Padlocks may be wrapped by heavy metal iron stock. In this case, we will not have access to the padlock. If there are more than two of these padlock guard installations or modifications, it is necessary to abandon the lock removing technique and cut the door itself.

- Padlocks may be encased in a special box assembly of lighter metal (see illustration). In this case, familiarity of the lock type and guard assembly will indicate the bow (shackle) location under the metal box. The power saw’s metal cutting blade (aluminum oxide) will cut both cover and bow in a single pass.

- In rare cases, a metal locking pin may be affixed at the end of a screw-in, key-lock assembly (similar to locks that secure soda dispensing machines). In this case, simply pull the lock from each location as you would pull a simple cylinder, and, in most cases, the pin will come away also. If the pin doesn’t come away, grasp the end remaining with vise-grip or pliers and twist counterclockwise until the pin is free.

The door Itself

If we don’t see any readily accessible method of forcing entry through the lock, we don’t have time to discover an alternate means of gaining entry in a fire situation. We must cut the door with a circular saw or with oxy-acetylene equipment.

Listed in order from least desirable to most desirable, the methods of cutting these metal rolldown doors include:

Photo by Paul McFadden

- Cut a rectangle in the curtain of the door. This maneuver requires three cuts. The first cut (parallel to the ground) should be made as high on the door as possible in order to be effective. This is an extremely unsafe operation and should be discouraged and eventually removed from a department’s standard operating procedure as an accepted operational tactic. The danger of using a power saw horizontally is multiplied as the saw is operated above waist level; and cutting with a power saw in an overhead position increases the hazard a hundredfold.

- A single cut down the center of the door or curtain. After making a vertical cut down the center of the door, remove the slat above the uppermost locking pins. This will allow the upper part of the door to be pushed up into the winding drum. The slat below these pins are pulled next. Continue to pull the slats above and below each locking location all down the door. This will destroy the door’s integrity and the curtain can be removed in sections.

- Two cuts made parallel to the guide rails (about six inches in from the rail) from as high as the saw operator can reach to the base of the door. Pry out at the top of the cut and remove the highest accessible slat by the vise-grip assembly and a hook or pike pole assisting from the opposite side (see illustration). The cut section will fall down and can be removed after the initial attack has begun by simply removing the lowest accessible slat. This makes a safer, larger opening but it takes time. Note that after the two cuts are completed, the remainder of the operation and any aggressive attack on the fire depends on the removal of a slat the entire width of the cut section.

- Triangular cut. The triangular cut is the best method for gaining entry through roll-down metal doors for many reasons.

Also keep in mind that once the exhaustive, unsafe horizontal cut is completed, two additional cuts, one on each side of the door connecting with the horizontal cut and continuing downward as close to the ground as possible must be made before water can reach the fire and/or entry can be made.

NOTE: The vise-grip and dog chain accomplish this job very nicely. Stubborn slats may be “coaxed” along by gentle taps with a tool on the opposite side. However, note how many operations are necessary for success in gaining entry with this method.

Beginning in the center of the door or curtain, the saw operator starts his cut as high as possible and angles the saw (as close to 45° as he can) to the side and continues to the corner, trying to get as close to the base of the door as possible. Returning to the apex, he performs a similar cut to the other side. As the second cut begins, the door begins to fall away.

Photo by Bob Athanas

During this forcible entry operation, an exterior protective hose stream (a handline or large caliber stream) can be applied, if necessary, to protect the saw operator and/or the occupants or the searching firefighters above the fire. After the cut and resulting opening is made, and additional forcible entry (on the front door of the occupancy) is completed or the fire has vented itself through the glass, the nozzle may advance as low as possible into the occupancy.

Two cuts, a saw handling technique that’s as safe as possible, early water on the fire, rapid advancement (as low as possible). What could be better? Now the slats to the side may be removed, increasing the opening and thereby the ventilation.

Alternate means of entry

We can be sure that if roll-down doors are installed, alternate entry of the occupancy is also heavily secured. Concrete and block replace rear and side windows. Steel plating has also been found welded over these openings. The roll-down door is our best means of entry and ventilation (horizontally, anyway).

However, in cases where entry is bordering on the impossible, consideration can be given to gaining access from:

- Above—through the roof or flooring.

- Below—through the sidewalk cellar access to the interior stairs (if present) of the commercial occupancy.

- Adjacent—breach walls at sides or rear of the structure. Breaching partitions from adjoining occupancies, especially in one-story, row, commercial occupancies (taxpayers) is a relatively easy job. It’s not a good firefighting technique, but when direct horizontal entry is impossible, it is a good alternative.

- Rear—there may be instances where occupancies using these high security devices have not gotten around to securing other access areas. Check these possibilities. However, in most cases, the rear ofthe occupancy will present an even more formidable forcible entry problem. Our best, and usually most successful attack will still be at the security door itself.

Photo by Warren J. Fuchs

NOTES:

- Locking pins may be cut if there is enough space between the curtain and the channels (see illustration). This is accomplished with a metal cutting blade (aluminum oxide) or portable oxy-acetylene equipment. However, the cut must take part of the curtain to prevent the remaining pieces from still holding the door in position.

- In extreme life threatening emergencies, the door may be cut with the wood cutting blade (time cannot be allotted for changing the blade). The teeth, however, will chip off rapidly and fly with great velocity. The operator of the saw should be aware of this and keep himself fully protected and the area free of other personnel.

- In cases where arriving units do not have the equipment nor the expertise necessary to successfully force these high security doors, the entire assembly may be removed from the building. A maul or pick is used to loosen the cement around the base of the guide rails of the curtain. Once free, pike poles are used to pull the bases of the rails out and away from the building simultaneously. The entire door assembly, including the roller drum, should fall to the sidewalk. The area must be kept clear and pike poles should be rigged with rope (pull down hook) to keep the members further away from the door than the end of the hook handle as this operation is performed (see illustration).