BY JEFFREY POST

Each day across North America, a fire department responds to an incident requiring gas detection beyond the limits of a standard four-gas meter. These incidents include but are not limited to unknown odors, confined space and trench rescues, and chemical runs. In a large percentage of these calls, the first-due companies are not specialized hazardous materials units. With the development of regionalized hazardous response assets, although many fire departments now have access to photo ionization detectors (PIDs), they may overlook them as a valuable response tool. An emergency response organization will greatly increase its effectiveness and the level of protection it offers its employees (responders) by more frequently deploying a PID in response. Although some departments have these instruments, their use is shrouded in mystery and wordy user manuals. I offer below a user-friendly training tool to improve responder safety.

WHAT IT DOES

A PID measures volatile organic compounds (VOCs), a vast chemical family that includes common chemicals such as gasoline, epoxies and resins, paints, and almost all hydrocarbon chemicals (e.g., alkanes, ketones). A PID will also detect alcohols (e.g., ethanol, isopropanol, methanol) and the odorant mercaptan found in propane and natural gas. Typically, VOCs have a high vapor pressure at ambient temperatures, meaning the liquid is giving off vapor readily, which makes gas detection relatively easy. The main purpose of the PID in these types of spills and releases is to measure the toxicity of the atmosphere—i.e., its threat to responders’ health.

It is important to note that using a PID alone will not adequately protect the responder; it is crucial to combine a PID with other gas detection instruments—at a minimum, a four-gas meter (which detects combustible gases, oxygen enrichment and deficiency, carbon monoxide, and usually one toxic gas such as hydrogen sulfide) and pH papers. PIDs will detect some inorganic materials such as ammonia, hydrogen sulfide, phosphine, and nitrous oxides. Some of these gases are toxic by inhalation and are released from other compounds when they react with water; they can be found in the toxic-by-inhalation table in the green section of the Emergency Response Guidebook (ERG) (see page 345 in the 2012 edition). The PID is ineffective for measuring ambient air or oxygen levels, hydrogen cyanide, polychlorinated biphenyls (PCBs), radiation, freons, and acid/basic gases. When investigating releases, responders still need to rely on a multiresource approach to identify and qualify an environment.

The PID uses light to ionize a sample. When the gas sample is drawn into the meter, a light source will cause an electron to break off while the remaining sample is put through a grid where the ion’s current is measured. The current created is related to the gas concentration, and the value will be displayed as a readout in parts per million (ppm) on the digital display. Again, the meter is not capable of identifying the gas detected; it is just displaying its concentration in the atmosphere. One misconception with some meters is that the gas detected is identified on the display; many meters will display on the screen the PID calibration gas used, commonly isobutylene. There are two critical pieces of information you need to detect with reliable result: the strength of the PID lamp and the material’s ionization potential (IP).

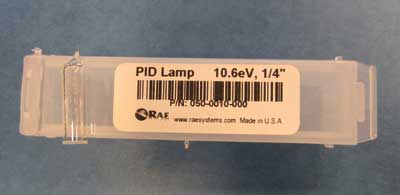

The lamp strength is expressed in electron volts (eV) for all PIDs and indicates the amount of energy available to cause the neutral molecule to break off and give the material a charge (thus ionizing). The eV strength will vary from instrument to instrument. The most common three eV strengths available are 9.8, 10.2, and 10.6; there is also 11.7 eV (photos 1, 2). This information is important, since the lamp will produce reliable readings only on materials with an IP at or below the lamp’s strength. Most instruments indicate the lamp’s strength during the start-up procedure. The material’s IP is the energy needed to cause the neutral ion to be removed and cause the ionization. Although one would think that selecting the lamp with the highest eV strength would be most appropriate, the 11.7 eV lamp is not as stable as the 10. 6 eV, and its lifespan is significantly shorter.

|

| (1) A typical photo ionization detector (PID) lamp. Always use gloves and the manufacturer’s cleaning solution when changing out lamps. Contaminants from skin may cause interference and impair accuracy. (Photos by Firefighter Dave Grills.) |

|

| (2) Common photo ionization detectors are available as a stand-alone unit (middle, silver) and in a five-gas combination meter (bottom, yellow). |

In the National Institute for Occupational Safety and Health (NIOSH) Pocket Guide to Chemical Hazards, the IP of chemicals is noted in the physical characteristics section. In addition to the NIOSH guide, the IP may be found on some material safety data sheets (MSDSs) as well as in databases such as the Wireless Information System for Emergency Responders (WISER) available from the National Library of Medicine. Again, it is important to match the IP against the lamp’s eV to determine whether the meter will be able to produce a reliable result. It is important to research the IP of a material even if you are familiar with its behavior. Some chemicals are difficult to ionize essentially because they are “built” better than others—i.e., they have strong bonds. One cannot make this assessment simply by knowing a chemical name or how it attaches to a hydrocarbon. Research materials will offer the most solid information and are more reliable than the chemistry courses of days long ago. Don’t memorize the chemistry; memorize where to look it up!

HOW TO USE IT

Ethanol has an IP of 10.47 eV, with 59.3 mm/Hg vapor pressure (as defined by WISER). This material is relatively mobile and detection should be easy. A responder with a PID equipped with a 10.6 eV lamp will be able to detect ethanol.

Carbon monoxide, however, has an IP of 14.01 eV. This is a common substance for which a direct-read sensor is available. Even the higher-strength 11.7 eV lamp will not effectively read this compound because the IP is greater than the eV of the lamp.

Even as the response team selects the correct lamp for the material, there is still work to be done. If the material is known, the team needs correction factors to determine the actual concentration, which is obtained by multiplying the gas’s correction factor by the PID meter reading.

The IP for ammonia is 10.16. A responder using a 10.6eV lamp is monitoring a release at a former bulk ice and cold storage facility. A pungent ammonia odor is in the air and the PID is reading 100 ppm. According to the PID’s manufacturer-supplied correction factor chart, the factor for ammonia is 9.7, so 9.7 × 100 yields an actual concentration of 970 ppm.

Often, specialized hazardous material teams will do this later in an incident. Many first responders operating at the hazmat operations level using the PID are mainly concerned with identifying the presence of the VOC and implementing proper personal protective equipment (PPE) levels for the incident. Many response agencies use the PID as a leak detection tool as well as a PPE guidance tool. The PID’s sensitivity and reliability, when used within its parameters, will enable teams to locate and define a spill’s footprint. Such information, used in conjunction with the ERG recommendations, is valuable in more precisely determining protection zones, which may be increased or decreased as a result.

MAINTENANCE

Of course, proper maintenance is essential to accurate readings, since condensation on the lamp will possibly affect this accuracy. Hence, responders must ensure the meter is properly maintained and use dust/humidity filters when operating whenever possible, even in quarters during training.

Most manufacturers make a four-gas meter with available PID. Since the PID will meter for VOCs, it tells us we are detecting materials that present a toxicity hazard to responders, primarily through inhalation. Many, if not most, of these materials are also combustible or flammable. The PID will detect the presence of the flammable material usually prior to the LEL sensor detecting or alarming. Again, this will prompt responders to don protective breathing equipment, identify a spill, and confirm or refine protective distances.

For example, gasoline is flammable at 1.4 to 7.8 percent (as defined by WISER); however, it has a permissible exposure limit/time weighted average (PEL/TWA) of 300 ppm. The PID will detect the presence of gasoline as a toxic hazard at 300 ppm well before it detects the flammable levels (14,000 ppm). Manufacturers cite this example in their instrument specification sheets, which is valuable and relevant information to responders.

This information is important to responders, since the initial zones established according to the ERG can be refined for such an incident involving a gasoline spill and the data will also offer more accurate exposure information for affected employees. In this example, you can use the PID to track product migration through the air or in a waterway. Again, later-arriving agencies may do this, but if the fire department is so equipped, it will be able to define this ahead of time and potentially limit the impact on the environment. Each response agency must pair the need for quick reconnaissance against other information that may indicate highly toxic materials, such as those that are skin absorption hazards and require a higher level of PPE.

The PID will also aid companies performing decontamination duties. Whether it’s an emergency decon of an injured victim or a technical decon of emergency responders, using a PID at the clean/cold side of a decon line will verify the cleaning procedure’s effectiveness for removing VOCs. At a minimum, the decon officer should use a PID and pH paper to confirm the effectiveness of wash procedures in decon operations if VOCs are involved.

As always, training is critical; company officers and instructors can consult manufacturer data sheets, as well as other texts such as Hazardous Materials Air Monitoring and Detection (second edition) by Christopher Hawley and Hazardous Materials: Managing the Incident (third edition) by Gregory Noll and Michael Hildebrand.

The theory and implementation may be technical, but in using the PID as a response instrument, any first-due company can effectively gather information that will protect responders and civilians in proximity to the release and prevent impact to the environment.

As with any tool in the fire service, consistent training is needed to maintain proficiency. It requires far more technical prowess and decision-making skills to operate a fire department pump than to properly use a photo ionization detector at your next incident.

Author’s note: Thanks to Connecticut Department of Energy and Environmental Protection Supervisor Jeff Chandler for his assistance with this article.

References

U.S. Department of Transportation, Pipelines and Hazardous Materials Administration. 2012 Emergency Response Guidebook, http://phmsa.dot.gov/staticfiles/PHMSA/DownloadableFiles/Files/Hazmat/ERG2012.pdf.

National Institute for Occupational Safety and Health. NIOSH Pocket Guide to Chemical Hazards, www.cdc.gov/niosh/npg/.

National Institutes of Health, National Library of Medicine, Wireless Information System for Emergency Responders (WISER), http://wiser.nlm.nih.gov.

JEFFREY POST is a 16-year veteran of the fire service and a career captain in southeastern Connecticut. He also volunteers with the Mystic (CT) Fire Department, the Gales Ferry (CT) Volunteer Fire Company, and the Connecticut Eastern Regional Response Integrated Team hazardous materials response team.