Training Notebook ❘ By BRIAN S. GETTEMEIER

When it comes to extinguishers in the fire service, firefighters often think about the 2½-gallon pressurized water extinguisher, also known as “the can” or “PW.” There are entire classes taught about the advantages and abilities of the pressurized water extinguisher. Very little is talked about, written about, or trained on when it comes to fire extinguishers in the fire service beyond a pressurized water extinguisher.

- The Importance of Industrial Firefighters

- Industrial and Municipal Fire Department Interface

- Industrial Firefighting: Preparing Your Fire Department for Response

Extinguishers can be a great resource to supplement our firefighting abilities, especially when it comes to commercial and industrial fires. For commercial and industrial occupancies, the extinguishers are readily available and often tailored for the hazards that exist in that occupancy.

Not All Extinguishers Are Equal

At the fire academy, we were taught the very basics of fire extinguishers, including the five classes of extinguishers, which follow:

- Class A (ordinary combustibles).

- Class B (ignitable liquids and gases).

- Class C (energized electrical equipment).

- Class D (combustible metals).

- Class K (kitchen class).

There is a difference between the proper-rated extinguisher for the class of fire and the most appropriate extinguisher for the fire. For example, dry chemical and carbon dioxide (CO2) extinguishers are both rated for Class C. However, if we have the choice between these two extinguishers, the CO2 would be the more appropriate extinguisher in most energized electrical equipment applications. We will cover more on this reasoning later in the article.

(1) A dry chemical and pressurized water extinguisher onboard an apparatus. (Photos by author.)

(2) A pressurized water extinguisher with an F-500 additive and a misting nozzle. You can find these extinguishers in coal-fired power plants.

(3) A hoseline working with extinguishers. Here, firefighters are extinguishing an ignitable, in-depth liquid fire with two hoselines and a 20-lb. cartridge-operated BC extinguisher.

Class A

Most of us know the effectiveness of a pressurized water extinguisher. When operating in a commercial or industrial facility, firefighters must identify Class A extinguishers beyond the standard pressurized water. For example, in coal-fired power plants, the accumulation of coal dust is something facilities constantly deal with; when it is stirred up, coal dust can create an explosive atmosphere.

Many coal-fired power plants will have pressurized water extinguishers that contain an extinguishing additive to assist in breaking down the surface tension of the water to allow better penetration of the water into the Class A materials. Furthermore, these pressurized water extinguishers may have water mist nozzles on them to reduce the risk of stirring up coal dust. These extinguishers are especially useful when extinguishing small smoldering coal fires and will operate very similar to a standard pressurized water extinguisher, but they will have an extremely limited range.

Class B

Dry chemical extinguishers will quickly interrupt the chemical chain reaction of the “fire tetrahedron.” In the absence of a foam line, the extinguisher can enhance our ability to quickly control an ignitable liquids fire. When we use an extinguisher with either a hoseline or a foam line, we gain the quick knockdown with the firefighting extinguishing ability of the other devices. To use the extinguisher with a hoseline, the hose team would approach the fire with a wide fog or a 30° power cone nozzle pattern. The firefighter with the extinguisher would stand just behind the fog stream and spray the dry chemical toward the fire through the fog stream. Extinguishers are also beneficial in 3-D flowing fires we encounter at an industrial event, a scenario for which foam application does not perform well.

The disadvantage to using an extinguisher on its own for Class B fires is that, by breaking the chemical chain reaction of the fire tetrahedron, you are left with the three essential elements of the “fire triangle.” A reignition is always a risk when using an extinguisher solely as a lone agent. Firefighters must always back away from the fire once it is extinguished. An appropriate fire watch must be put in place to ensure the fire does not reignite.

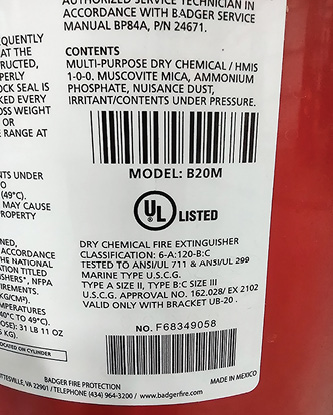

(4) A high-flow, stored-pressure ABC dry chemical extinguisher.

(5) A CO2 extinguisher.

(6) A clean agent extinguisher.

(7) A Class D extinguisher.

(8) In this application, first responders would have access to a dry chemical on one side of the corner and a CO2 on the other corner.

The dry chemical and the CO2 extinguishers are both rated for Class B fires, with the dry chemical extinguisher being the most appropriate extinguisher in most Class B fires applications. Dry chemical extinguishers will have a higher rating for Class B fires when compared to a similar-sized CO2 extinguisher. The dry chemical extinguisher also has greater effective stream reach vs. a CO2 extinguisher. Dry chemical is nontoxic by today’s standards, but it is a mild respiratory irritant. In any case, firefighters should take precautions to avoid inhaling the dry chemical agent.

When you are at a site, look at the B rating label of the extinguisher. A 20BC extinguisher is effective on 20 square feet of burning liquid. The B rating is based on 40% of the area a trained operator can put out with the same extinguisher. An extinguisher of similar size with a different agent may have a greater BC rating. For example, if you took a 20-lb. ABC extinguisher, you would have a 6A60BC rating with an approximately 20-foot effective range. A 20-lb. extinguisher containing Plus 50 is not rated for Class A fires and has the same 60BC rating, but the user gains two feet of effective reach. A 20-lb. extinguisher containing Purple K has an 80BC rating, essentially giving the novice user another 20 square feet of effective firefighting ability. The Purple K extinguisher has a stream range of 30 feet, allowing for greater distance between the user and the fire. Extinguisher companies also make a high-flow extinguisher that will dump a tremendous amount of dry chemical onto a fire in a very short amount of time.

When it comes to extinguishing ignitable gases, we should make every attempt to shut off the gas supply. Although extinguishing the fire eliminates the heat and exposure risk, if the fuel is not shut off, raw gas will be pumped into the area, which could lead to explosive results.

Class C

There are several options of extinguisher agents available for Class C fires, dry chemical, CO2, and clean agents. When fighting Class C fires (energized electrical equipment), extinguishers can be very effective. Deenergization is the only way to truly control the fire. Also, as long as the equipment is energized, there will be heat energy.

(9) A 100-lb. wheeled CO2 extinguisher.

(10) A wheeled dry chemical extinguisher.

(11) An operating label that allows users to identify the classes of fires for which the extinguisher is rated. It also identifies how far back the user should start. In addition to this being a safety measure, the rule of thumb is that this starting distance is roughly half the effective range of the extinguisher.

Dry chemical is commonly the most available Class C agent. The issue with dry chemical is BC agents can be mildly corrosive, and ABC agents cause melting of the extinguishing agent to achieve an A rating. In either case, dry chemical agents can create damage to electrical components in the area. The application of the dry chemical extinguisher will fix the immediate issue: the fire. The trouble for our customer is that deploying a dry chemical extinguisher can damage the surrounding electrical equipment, creating a recovery issue. Dry chemical extinguishers are appropriate for Class C fires but, given the choice, firefighters should consider a clean agent or CO2 extinguisher first; these extinguishers are a better fit when it comes to the long-term recovery needs of our customer. A little-known issue for firefighters with dry chemical agents is once they are expelled from the extinguisher onto a piece of equipment, they will begin to collect moisture, which can then create a little current leakage, and the expelled agent is no longer nonconductive.

Clean agents are specialized agents designed to be applied to critical electrical components and leave little to no residue. These extinguishers will have minimal impact on surrounding equipment. Clean agent extinguishers are typically found in server and telecommunication rooms as well as rooms that contain critical electrical equipment. These extinguishers are not as common as other extinguishers. A clean agent extinguisher operates on the same operating principle as a stored pressure dry chemical extinguisher.

The fire service is a little more familiar with CO2 extinguishers, which are heavier than traditional extinguishers of the same size because of their thick wall construction to contain the compressed liquid gas. The disadvantage of CO2 extinguishers is their effective range; with a handheld unit, there is not much range, which is typically three to eight feet. The advantage is they are typically more available than clean agents and, similar to clean agents, will not leave a residue on electrical components. Hold the extinguisher by the handle and not the horn. In addition to the potential for frostbite, there is a static electricity shock hazard because of the expelling gas. In certain weather conditions, the user may encounter a little static electricity “bite” in the handle, which can be quite unnerving when you are fighting an electrical fire.

(12) A rating label.

(13) A cartridge-operated extinguisher. This is commonly found in industrial applications.

Deenergization is always the best method to begin to control an energized electrical fire. As long as the equipment is energized, the heat element is going to be present. The fact is, in industrial applications, some equipment cannot be shut off or a proper shutdown may take an extended period. The abrupt shutdown of equipment can be costly if not catastrophic. Firefighters may need to control the fire while the proper shutdown is occurring. In these cases, apply the agent until no more combustion is visible, and then back away. Continue to observe the equipment and, when the fire begins again, apply another blanket of agent. When selecting extinguishers for electrical equipment fires, clean agents and CO2 are more appropriate agents compared to dry chemical.

Class D

Most municipal firefighters have limited experience with Class D fires. Encounters with combustible metals are typically confined to automobile components. Firefighters can quickly overwhelm the limited combustible metals found in automobile components with a handline. Commercial and industrial facilities that have combustible metals will often have a dry powder extinguisher designed to fight a fire involving a particular metal. Unlike the other classes of fires with extinguishers, a Class D is not a one size fits all and will not work on all Class D fires. Firefighters should familiarize themselves with these extinguishers, the metals they extinguish, and their operating principles.

Class D extinguishers operate similarly to an employee at a garden center who waters the flowers—a type of “up close and personal” raining down of an agent onto the burning product. This agent commonly melts and creates a crust to smother the fire.

Beyond Handheld Dry Chemical Extinguishers

Some facilities will be equipped with wheeled extinguishers, which may contain a dry chemical agent or CO2. A dry chemical extinguisher will typically carry 150 to 350 pounds of dry chemical extinguishing agent. Once again, during a preplanning visit, look at these extinguishers’ rating. Firefighters must realize these nozzles have a significant nozzle reaction and must have their feet firmly planted with a good grip on the nozzle. To use these extinguishers, position the wheeled unit. Turn on the nitrogen tank (this could be a traditional turn knob or a quick-flip lever, and make sure the unit is completely on), deploy the hose completely out of the holder, firmly plant your feet, open the nozzle to purge the nitrogen, and aim at the fire and sweep side to side.

Facilities may also have wheeled CO2 extinguishers, which can commonly be found in two sizes: a 50-lb. single tank or a 100-lb. double tank. When attacking a fire with the 100-lb. double tank configuration, firefighters should open both valves completely.

Performing an Extinguisher Size-Up

When we are identifying extinguishers for preplanning, training, or natural curiosity purposes, we should identify the following components:

- The class of fire. What classes of fire is this extinguisher rated for?

- The rating. Look at the back label to identify how much fire the extinguisher will extinguish.

- How far you should stand back before use. The second line on the operating placard will indicate how far back you need to stand before starting your application. We use this line for two reasons. First, to ensure we are not too close to the fire. Often, in the initial application, the fire will appear to get bigger before it begins to retreat. Second, and a quick rule of thumb, is that the distance you start back is about half the effective range of the extinguisher. For example, if you were to start 10 feet back, the effective range of that extinguisher will be approximately 20 feet.

Firefighters must remember that a rapid sweeping of the extinguisher nozzle will greatly reduce the effective range of an extinguisher. When using facility fire extinguishers, the fire service should use these devices as a supplemental device. For our safety, we should always have handlines in place as a backup. A reputable industrial customer will perform monthly inspections of fire extinguishers to ensure they are charged and located where they are supposed to be. Annually, extinguishers will be inspected by a trained extinguisher field agent. During annual fire safety inspections, firefighters must ensure the extinguishers have been inspected in the past year. An extinguisher company will perform the annual inspection and place an inspection tag on the extinguisher. During your inspection, ensure the annual inspection tag is in place.

It is important that, during preplanning tours, firefighters familiarize themselves with the extinguisher resources available. Large facilities may have a cache of extinguishers available for emergency response as well as to replace extinguishers that have been expelled during an emergency response.

Training Resources

There are several resources available for training. If you have large industrial facilities in your area, ask their personnel what type of extinguisher training they offer and if the fire department can participate. For example, in St. Louis, Missouri, the local natural gas utility has a fire school that trains its personnel on using handheld, cartridge-operated extinguishers that extinguish a variety of natural gas fires. The utility offers local firefighters the opportunity to attend this training.

Extinguishers can be a very useful firefighting tool, especially when facing a Class B or C fire. Firefighters must familiarize themselves beyond the pressurized water extinguisher. When conducting company safety inspections or preplanning on large commercial or industrial buildings, take some time to look at the extinguisher beyond its annual inspection tag. This is especially true for facilities with special hazards, as these extinguishers may be the enhancement we need to successfully mitigate these incidents.

BRIAN S. GETTEMEIER is a 30-year fire service veteran, spending the past 27 of those years as a career firefighter and engine company captain with the Cottleville (MO) Fire Protection District. He is a second-generation firefighter and has a bachelor’s degree in fire service management from Southern Illinois University—Carbondale as well as numerous state certifications. Gettemeier also teaches all-hazards classes for numerous municipal and industrial organizations throughout the states of Missouri and Illinois and instructs at FDIC International.