Down to Earth Talk About Nozzles

HOSE AND FITTINGS

Nozzles may be one of the most critical tools the fire fighter has at his disposal. This article focuses on various types of nozzles and the range of pressure and volume over which they can be effectively utilized. A functional understanding of nozzles, streams, volumes and pressures can make the difference between bringing a fire under control and having it burn until it runs out of fuel.

There is no way to count the number of times the cry has come from the end of hoselines for “More pressure!!!” or “More water! I need more water!!!”

There may be found text after text that discusses the pressure and volume relationships of fire streams. All too often it seems that these relationships are viewed by fire fighters as topics to be studied for promotions only. Odd as it may seem, some fire officers are intimidated by nozzle theory. In fact, there is one fire department where thousands of dollars worth of “constant pressure/variable flow” nozzles are locked away in a cabinet because the chief doesn’t understand how to use them.

A functional understanding of streams, nozzles, volume and pressures should be possessed by the nozzleman, the pump operator and the officer. This discussion centers principally on nozzles. Several nozzle types and their relative performance will be compared with regard to the useful range of pressure and volume over which they can easily be utilized.

Most certainly, the nozzle can be classified as a tool. Perhaps it is one of the most critical tools the fire fighter has at his disposal. Just as the efficiency of an axe is only as good as the knowledge and skill of the man using it, a properly used nozzle can decide whether a single handline will be effective or must be backed up for efficiency. Improper selection of line and nozzle combination can send the crew scurrying for a better combination if the attack does not go right.

Consider what it is that causes a fire to either be brought under control or to continue burning until it runs out of fuel. Success is determined by whether or not the correct gpm is properly applied. Now, the needed gpm can be applied by a lot of fire fighters running around with buckets in their hands, or a 2 1/2-inch supply line with an open butt, or a fire stream using a proper nozzle. So, what is the difference in the delivery methods? The difference lies in the nozzle pressure (tip pressure) used to “throw” the required quantity of water at the fire. This concept is perhaps more important than it might seem on the surface. Volume causes the fire to become controlled. Pressure is the factor which allows the volume of water to be projected upon the fire in an orderly and efficient manner. Pressure Continued on page 60 must be carefully selected to provide proper stream formation as well as reasonable nozzle reaction forces.

Continued from page 26

Put another way, it must be understood that simply “raising nozzle pressure” is not necessarily the solution to a fire suppression problem. As a fire grows in size and intensity, higher gpm flows are called for. Or, as the saying goes, “There is a time to put the l 1/2-inch line away.” Therefore, this situation does not necessarily call for pumpers to pump higher pressures so much as it calls for larger hose and tips at approximately the same pressures.

Consider the “playpipe” type nozzle. This nozzle is used with machined straight tips. The tip is smooth and, at proper nozzle pressures, provides a highly concentrated and well-formed stream. Nozzle discharge is a function of nozzle pressure. No matter how one looks at an application using the nozzle, it is a one man job if the line needs to be kept mobile. To effectively change the gpm flow rate on this appliance, the line must be shut down, a new tip selected, and the gate opened again. Not an easy or convenient task to perform.

A commonly used nozzle is that appliance known as a variable pattern/ constant flow device. This means the size of the orifice is manually selectable.

The constant flow label indicates that the gpm discharge of the nozzle remains constant as the shape of the stream is changed from wide fog to straight stream. Realize that there is no straight stream feature on these nozzles in the same context that solid stream is used on the straight tip nozzles. Actually, the straight stream feature is a narrow, hollow, fog stream. This familiar nozzle is very often found on attack lines on standard pumpers. Note that between the pivots for the shut-off gate is the selector that allows the user of the nozzle to select desired flow rates in gpm. The designer went to a lot of trouble to provide this feature. It would be appropriate to review what it does for the user. Depending on the manufacturer, the selection of flow rates marked on the neck of the nozzle typically read 30, 65, 95, or 125 gpm. For this discussion, the exact numbers are not important. The only reason for this feature lies with recall of the premise that each fire situation calls for a certain flow rate, in gpm, propelled by a proper nozzle pressure. For example, most grass fires can be tamed with a 30 gpm flow. An auto fire, depending on what is burning, can be brought under control with 65 gpm. At the top of the selectable range, this nozzle could effectively subdue a working room fire in a frame dwelling. Of course, the 125 gpm delivery would provide an adequate flow in all cases. However, conservation of water, control of thermal balance and minimizing water damage would dictate that a skilled fire fighter make a selection appropriate for the problem.

It must be understood that such “band-aid” tactics, such as simply calling for additional pressure from the pump operator in order to increase the water flow to combat a growing fire suppression problem is not necessarily the best solution. Larger hose and nozzle openings operated at the same pressures may be the answer.

Finally, enter the new kid on the block—well, at least no more than 10 to 12 years old. This is the constant pressure/variable flow nozzle. The prime feature of this nozzle is to have the nozzle pressure remain essentially constant over a wide range of gpm nozzle flow. This ability to maintain relatively constant pressure insures good stream characteristics without the constant attention of the nozzleman.

These nozzles are typically designed to effectively flow from about 50 gpm up to approximately 220 gpm. The nice thing about these nozzles, if operated properly, is that nozzle pressure will remain almost the same over the entire operating range. What manufacturers have provided the nozzleman with is an updated version of the selectable nozzle. Now the nozzleman will not be required to feel for the position of the gpm selector. Hunting for the flow position can be a real chore with gloves on. The automatic nozzle, with a properly sized handline attached, can become a super weapon. With a 1¾inch line supplying one of these nozzles, flow rates up to 200 gpm or more can be attained. So this combination supply line, nozzle and nozzleman, can almost duplicate the firepower capabilities of anything from a booster line to a 2’/2-inch line.

How is this nozzle set up? Engine pressure is set for the maximum design flow, taking into account supply line size and length of the stretch and a nozzle pressure of about 100 psi. The nozzle gate is used not only as an on/off control, but also as a flow-rate controller. Essentially, the nozzle gate introduces the appropriate amount of pressure loss in the nozzle assembly so that the pre-set nozzle pressure plus other losses equal the engine pressure. By partially opening the gate, a reduced flow will be obtained. But the pattern and characteristics of the stream will be proper because the nozzle pressure will be automatically maintained at approximately 90 psi to 100 psi. If the gate is opened fully, then the maximum flow rate will be attained, still with an appropriate nozzle pressure and good stream characteristics. In summary, the nozzleman cracks the nozzle gate only as much as required to “throw and shape” the gpm needed for the desired suppression. The nozzle pressure takes care of itself.

The nice thing about constant pressure/variable flow nozzles is that nozzle pressure will remain almost the same over the entire operating range. What manufacturers have provided is an updated version of the selectable nozzle._

With an adequate supply line and minimum flow rates, the fire fighting team can establish a protective pattern for advancing into a heated area. Using nominal flow rates, the team can extinguish small fires without using excessive flow rates that would upset indirect extinguishment techniques, and yet be able to advance down a hallway without fighting excessive back pressure. Should the team come upon a heavily involved area, they can cease its advance, take a strong stance against back pressure, and give the fire area a full-flow gpm application. With properly coached teams, these nozzles have the ability to operate longer under adverse conditions because the team is not expending a lot of energy fighting the nozzle.

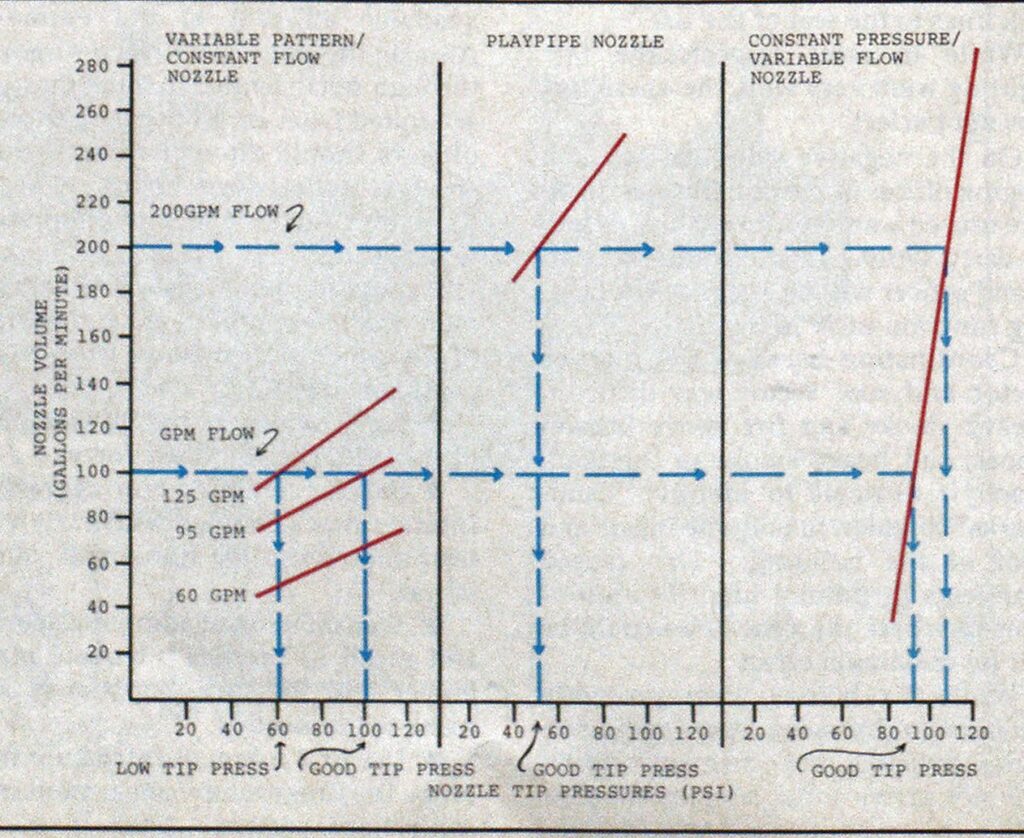

The chart (page 26) displays a set of graphs that relates the three different nozzles. The vertical axis displays volume in gpm. This axis is to be used on all three graphs, the left, middle and the extreme right. The horizontal axis displays similar nozzle pressures for each of the three nozzles discussed.

Note that on the left graph there are three lines. These lines display the performance of the variable pattern/ constant flow nozzle depending on which position the gpm selector on the neck is set. Remembering that this type nozzle does not work well at 50 psi or less, it is observed that the nozzle is complicated for the user, and needs attention to the various adjustments as it is brought into action on various fire conditions.

The middle graph displays the operation of the 2 1/2-inch playpipe with a 1-inch smooth bore solid tip. This is a practical and common fireground setup. The discharge gpm ranges from 190 gpm to 250 gpm in these calculations. Nozzle pressures from 40 to 80 psi are displayed along with resulting volumes.

Observe, the extreme right graph displays a typical constant pressure tip marketed by at least three major manufacturers. It is of interest to note that this single nozzle has the theoretical ability to perform adequately in any application for which the other nozzles, left and middle graphs, might be selected. Admittedly the straight stream of the constant pressure nozzle may not be as effective as the solid stream of the smooth bore nozzle. But overall, it is a reasonable compromise. The automatic maintenance of a nozzle pressure near 90 to 100 psi insures a reasonable water particle formation for good stream conversion.

In the preceding discussions, it is assumed that the pump operator really knows his job. He must be aware of the orifice size or the position of the gpm selector control on the nozzle. With the constant pressure/variable gallonage nozzle, his job is much easier. The engineer sets up as if the nozzle gate is to be used wide open. Thenozzleman then controls the gpm at the nozzle.

In summary, it is important to understand the reasons certain pressures are needed on certain tips. Lower tip pressures are needed for solid streams, higher pressures for fog streams. Straight streams are to penetrate, fog streams to provide maximum water surface area for heat absorbtion purposes. “Gallons per minute” rates are required to absorb heat from fire settings. The larger the heat source, the higher the gallons per minute required. “Nozzle pressures” are required to propel the water quantities onto the fire source. If the pressures are too low, then the throw of the water may be inadequate. If the pressures are too high, then the streams may be inefficient. Enter into the discussion the factor “nozzle reaction” and the scene is complete. These three factors are intertwined. This intertwining needs to be understood by each and every fire fighter, regardless of rank. While the subject can be approached in a theoretical, mathematical and analytical fashion, it is certain that an afternoon working with a selectable and a constant pressure nozzle will bring the message home.

Editor’s Note: A strong word of caution in using constant pressure nozzles when engaged in interior fire fighting at structural fires. The nozzleman may, at times, get a false indication of the “abilities” of the stream that he controls.

Due to forces uncontrolled by him personally, (serious kinking in the stretch; reduced hose diameters as a result of physical pressure from poorly parked apparatus; a burst hose length; reduced engine pressure; etc.) the water flow may become dangerously low. Because of a constant pressure nozzle, all reliable physical indicators may become unreliable. The reduced orifice, which will result because of the lower flow, will continue the physical characteristics of the stream as if nothing had happened. Nozzle reaction will remain relatively constant. The firmness of the hose line will not diminish much in quality. The visible reach of the stream will in no way be diminished. What will diminish, however, is the pre-calculated water flow—and it may be impossible for interior fire fighting forces to keep up an aggressive attack, allowing the fire flow to overcome them.