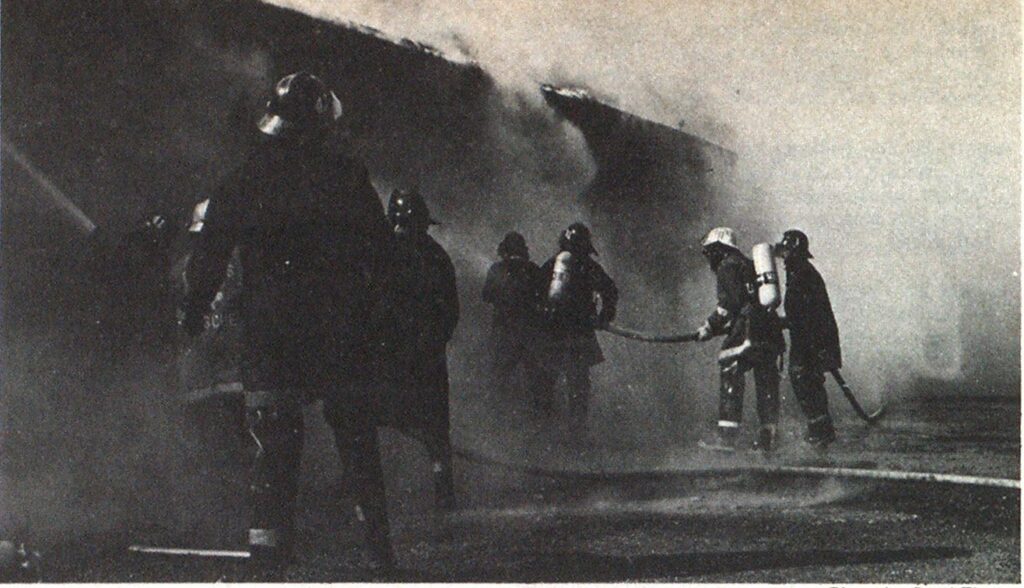

Delayed Alarm, Lack of Water Are Factors in Egg Plant Fire

FEATURES

Photo by Gerri Finner

An attempt by employees to extinguish a small fire before notifying the fire department plus the lack of sufficient water pressure resulted in a major blaze which destroyed the second floor of an egg processing plant in East Windsor Township, N.J.

The Agway Company building is a 250 X 150-foot, two-story, brick and wood frame structure used as a wholesale egg distribution facility. It is built on a slight hill, which allows for ground access to the second story on the south side of the building. The first floor of the building is used to grade and store eggs. The second floor houses the offices and is also used to store cardboard and plastic packaging materials for the eggs.

On a warm sunny day April 8, 1980, two overhead doors on the south side of the building were open. The fire originated in a stack of cardboard cases near one of these doors. Employees attempted to put out the fire with water and dry chemical extinguishers. During this time, smoldering cartons which were thought to be extinguished were left against a wooden divider under the overhang. It ignited.

Aid requested

At 3:07 p.m., East Windsor Volunteer Fire Company 1 and East Windsor Rescue Squad 1 received an alarm for the fire. The East Windsor Volunteer Fire Company 1 had in service a 1250-gpm pumper, a 750-gpm reserve pumper, a 75-foot aerial ladder truck, and a 6000-gallon tanker. A 1000-gpm pumper was out of service. Chief Sam Forman and Assistant Chief Andy Fritz were at the firehouse and immediately responded to the fire. Since one of the East Windsor pumpers was out of service and knowing the potential for poor water supply, the chief called the Hightstown Engine Company to respond with a pumper and a 5000-gallon tanker.

The two chiefs arrived on the scene reporting smoke from the rear, or south side, of the building. Forman checked the front of the building to make sure no one was in the building and to set up an initial command post. Fritz went to the rear to size up the fire. By this time the fire had spread into the building, growing and being fueled by the cartons and egg crates.

After receiving the report of a rapidly spreading interior fire, Forman requested a full mutual aid response of two pumpers, a Telesqurt, an 85-foot aerial, and a rescue truck from Hightstown and a 1250-gpm pumper from East Windsor Volunteer Fire Company 2.

More apparatus arrive

Hightstown Engine 413 was next on the scene and attacked the fire from the south side of the building with one 1 1/2-inch line for the exterior fire and one 1 3/4-inch line for the interior fire. East Windsor Tanker 426 arrived and began to supply Engine 413. East Windsor Company 1 Engine 423 arrived and took the hydrant at the northeast corner of the building. This hydrant is at the end of the Borough of Hightstown water system and was known to flow about 300 gpm. The crew of Engine 423 was attempting an attack on the fire from the front with a 2 1/2-inch and two 1 1/2-inch lines.

It was apparent that more water would be needed to contain the fire, which was still spreading, and Forman gave this responsibility to Hightstown Chief Larry Blake. Blake ordered Hightstown Engine 412 and East Windsor Engine 462 to drop their 4-inch lines to hydrants at Hightstown High School, some 1300 feet from the fire.

Additional equipment was also necessary to get the fire under control, so Forman requested Washington Township Fire Company to respond with a Telesqurt and pumper and Cranbury Fire Company to respond with a pumper. West Windsor Fire Company sent a pumper to stand by for East Windsor, and Applegarth Fire Company in Monroe sent a pumper to stand by in Hightstown. A special call was placed to the DeCoo Fire Company in Hamilton Township to respond with their Unit 152, a cascade and light plant.

With the water supplied from Hightstown Engine 412 and East Windsor Engine 462 to apparatus on the fireground, the fire was slowly stopped. Throughout the fire fighting a strong wind out of the south kept thick smoke near the ground, forcing all those on the north side of the building to wear breathing apparatus, including pump operators. Soon afterward, Hightstown Engine 412 was forced to shut down after losing oil pressure. This resulted in a reduction of water to the fireground and the fire again spread.

Water supply was also becoming a problem since the Hightstown system, which was supplying water, had two wells shut down. Forman and Blake discussed the problem, and they decided to set up a tanker shuttle. Requests were made to Washington Township, Cranbury, Applegarth, and Allentown for tankers, bringing the total number of tankers to six. West Windsor Engine 434 relocated from East Windsor Firehouse to a hydrant at Hickory Corner Road and Route 130, about half a mile from the fire, to fill tankers.

Fire controlled

Forman declared the fire under control at about 5:30 p.m., but many hot spots had to be extinguished and extensive overhaul had to be done. Units were on the scene until 9:30 p.m.

Several fire fighters were treated at the scene by members of the East Windsor Rescue Squad for smoke inhalation and one fire fighter was taken to a hospital for burns on his arm received when a drum of lacquer exploded.

A total of 125 fire fighters from nine fire companies battled the blaze, which caused damage estimated at $250,000.