BY STEVE SMITH

Commercial vehicles fueled by compressed natural gas (CNG) are everywhere in North America, from rural America to the major metropolitan cities. You have probably seen one but did not realize it or the potentially serious situation posed if that vehicle were on fire. Below, I will cover the properties of natural gas; identifying commercial CNG vehicles; how, where, and when such vehicles are refueled; how the CNG system is built and installed on different commercial vehicles; and, most importantly, what to do and what not to do if a commercial CNG vehicle is on fire, based on industry and government agency recommendations.

|

| (1-2) Photos by Billy Leach. |

Natural Gas

Natural gas is a combustible mixture of hydrocarbons. Although natural gas is primarily methane, it can also include ethane, propane, butane, and pentane. In its purest form, such as the natural gas delivered to your home, it is almost pure methane. Methane (CH4) consists of one carbon atom and four hydrogen atoms. The distinctive “rotten egg” smell of natural gas is mercaptan, an odorant added to it before it is delivered to the user to aid in detecting any leaks. Natural gas has a specific gravity of 0.55 to 0.64 (air = 1.00), which makes it lighter than air. According to the federal Environmental Protection Agency, compared to gasoline-fueled vehicles, CNG-fueled vehicles’ carbon monoxide emissions are 90 to 97 percent less, and carbon dioxide emissions are 25 percent less. Nitrogen oxide emissions can be 35 to 60 percent less, and other nonmethane hydrocarbon emissions can be 50 to 75 percent less.

CNG Vehicles

Medium- and heavy-duty commercial CNG vehicles include dump trucks, cement trucks, garbage trucks, buses, semitractors, delivery trucks, and even fire apparatus. They are easy to identify, even from a distance, and are most often for local use only. Such vehicles have a cylinder rack system built behind the cab or on top of the vehicle with an enclosure built around it. This enclosure has holes drilled on the sides or the back so that maintenance personnel can access the tank valves to open and close them. A vehicle may have an elongated saddle cylinder marked “CNG.” Buses with CNG today completely enclose the cylinders for a sleeker and aesthetically pleasing look. Per National Fire Protection Association 52, Vehicular Natural Gas Fuel Systems Code (2016), these vehicles are identified with a blue diamond decal with the white letters “CNG” on the right rear of the vehicle (photos 1-2).

Refueling

Commercial CNG vehicles may be refueled at their place of business; these sites have a long fueling island where these vehicles park overnight and refuel. Fleet CNG vehicles may be fueled overnight because the ambient outside temperature will be lower, which allows more fuel to be compressed into the cylinders. Similar to filling self-contained breathing apparatus (SCBA) bottles, filling the CNG cylinders too fast creates heat that reduces the amount of product that will fill the cylinder. Companies can also “fast fill” the cylinders, which takes only minutes. The refueling connection may be in the vehicle’s front bumper, on its side where a conventional fuel cap would be, in a box marked “CNG” between the driver’s door and the rear wheels, or in the rear. CNG systems on vehicles are designed for the customer and usually hold as much as the equivalent of the diesel fuel tank on that vehicle.

|

| (3) Photo courtesy of the Indianapolis (IN) Fire Department. |

CNG Garbage Trucks

A leading waste services provider converted 425 vehicles in one division to CNG and annually saved about three million gallons of diesel fuel. At an average savings of 90 cents per gallon for CNG, the company saved $2.7 million just in fuel costs. That company now has more than 5,000 CNG- and LNG-fueled vehicles in its fleet. The vehicles are much quieter and emit many fewer emissions and particulate matter into the air. From this point on, I will focus on CNG garbage trucks. Most commercial CNG vehicle systems are built on a rack with three to five cylinders typically. The cylinder the industry uses most is a Type IV metal-free construction. A carbon fiber or hybrid carbon/glass fiber composite consists of filament wound over a thermoplastic polymer liner; the carbon fiber and resin wrap is 100 percent of the strength of the cylinder. Attached to one end of the cylinder, sometimes both ends, is a valve with a thermal pressure relief device (TPRD) built into it. The cylinder construction and the TPRD valve play a big role. These cylinders with valves are then strapped to a rack system either on top of the vehicle (Figure 1, photo 3) or stacked horizontally in a rack behind the cab of the vehicle. The saddle tank-type cylinder is strapped to a rack that is attached to the frame of the vehicle. A metal shroud covers the rack to protect the cylinders from damage. Usually, there is about a three- to four-inch gap between the bottom of the rack and the roof of the vehicle to which it is attached, but not always. A rack system built behind the cab of the vehicle is sealed except for the holes in the door (if present) for the valves.

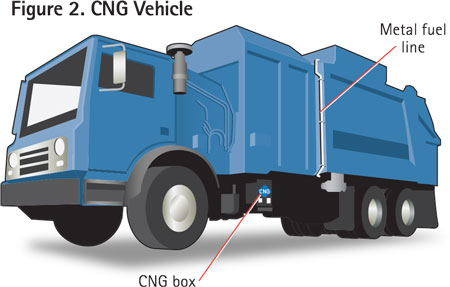

Metal fuel lines most likely will run from the top of the truck down to the bottom rail of the box, then forward to a box labeled “CNG,” which has a fill port, one or two pressure gauges, and a quarter-turn valve that shuts the gas off from the box to the engine of the vehicle. Note that the valves on the cylinders for the vehicle are still open. This box may also have a connection to empty the tanks for maintenance (Figure 2, photo 4).

|

| (4) Photo by author. |

Indianapolis Garbage Truck Incident

A CNG garbage truck on fire is a very serious situation. On such vehicles, three to five compressed natural gas cylinders are enclosed in a metal box that retains heat; it is most often located directly above the fire location. One cylinder manufacturer states, “Charring or melting of the composite materials, decals, valves, or other attachments is evidence of fire damage …. Flame impingement may result in the resin burning away from the cylinder exterior, leaving loose carbon fibers.” The trash collection industry primarily uses Type IV cylinders in which the carbon fiber wrap makes up 100 percent of the strength of the cylinder. If there is heat or flame impingement, a cylinder may fail; the product will be released; and a cylinder may become a projectile, much like the incident in Indianapolis, Indiana, on January 27, 2015.

|

| (5-9) Photos courtesy of the Indianapolis (IN) Fire Department. |

The fire was in the trash compartment of a garbage truck, and no flames impinged the cylinders. However, it is believed that the fire and the containment of the heat within the metal covering protecting the cylinders caused the breakdown of the composite materials and the fiber wrap on the cylinder. Two cylinders failed, and an extreme rupture happened. No fire resulted from the release of the natural gas. One cylinder flew a quarter of a mile, landing in the front yard of a middle school.

You can see the extreme damage that occurred when the cylinders failed. Notice how the 10-gauge steel sheet metal on the garbage truck was torn, the trash compartment was buckled, and the main supports were bent. Note also the location of the fire (indicated by black charring on the side of truck) in relation to that of the tanks on top of the truck (photos 5-9).

The TPRDs used on these cylinders are activated within a temperature range of from 212°F to 220°F. If they are cooled, they will not activate. TPRDs are designed to release the entire contents of the cylinder. However, for responder safety, assume that all cylinders are pressurized. Some cylinders may not have vented or the TPRD may not have activated.

After this incident, I spoke with representatives from one of the makers of these fuel systems for commercial use. They recognized this flaw in the system. They do not make the cylinders, but they are in contact with the makers; both are looking at ways to make the system safer. Possibilities mentioned include using a minimum Type III cylinder, which is an aluminum tank with carbon fiber wrap that will conduct heat to the TPRDs, an emergency system purge button in the truck cab that will allow the driver to quickly release the gas from the tanks, and redesigning the TPRD itself.

So what do you do if the contents of one of these garbage trucks is on fire? The first line of defense begins with your dispatchers. They must instruct the driver to release the trash immediately, no matter what the location: in a parking lot, on the street, in a field-wherever they are. Your dispatchers need to then ask if the truck has CNG on board and pass along this information to responding units so they can assess the situation from a distance.

If the driver cannot empty the load, then what? Do we cool the cylinders as we have been taught all these years? According the trash collection industry, the fuel system manufacturers, and the Clean Vehicle Education Foundation, if the garbage hopper is on fire directly under the cylinder enclosure or there is an engine fire on a truck with a vertical cylinder enclosure behind the cab, do not cool the tanks-let the vehicle burn! This goes against everything that we have ever been taught as firefighters. The 2012 Emergency Response Guidebook states to initially evacuate an area of 330 feet in all directions, farther if needed downwind. If we try to spray water on the cylinders, the water will never wet the cylinders because of the metal enclosure. Also, if we spray water toward the cylinders, it may just cool the TPRDs and defeat their purpose and increase the volatility of the situation tremendously. This is partially what is believed to have happened in Indianapolis.

The Indianapolis (IN) Fire Department used an elevated master stream to spray the cylinders, but it believed it is possible that all personnel did was cool the TPRDs, which did not activate. As a result, the exterior of the cylinders broke down from heat trapped inside the enclosure; finally, a cylinder ruptured. If you allow the fire to burn, the TPRDs, hopefully, will work properly and activate and control the gas and fire, and you should not have an incident. Do not at any time attempt to shut the valves on the cylinders off!

Commercial CNG vehicles are very safe and significantly reduce emissions and pollution. When they are on fire, however, special precautions and altered firefighting techniques must be used for everyone’s safety. As firefighters, we are trained to put the water on the fire, but we cannot in these situations. Take the time to set up the scene, evacuate the area, and let the vehicle burn in the above-mentioned situations. Our job is to save life and property-life is the first priority. This does save lives and significantly reduces the potential exposure to injury or death in these situations. Knowing how to identify these vehicles is the first step in protecting yourself and the public. Waste Management, Inc. invites any local fire department to its sites to conduct training on its CNG vehicles and fueling stations.

STEVE SMITH retired as a lieutenant with Arvada (CO) Fire Department after serving 26 years. He has an associate degree in fire science from Red Rocks Community College and is state certified to fire officer I, hazmat-operations level, driver/operator-aerial, and emergency medical technician-basic.

More Fire Engineering Issue Articles

Fire Engineering Archives