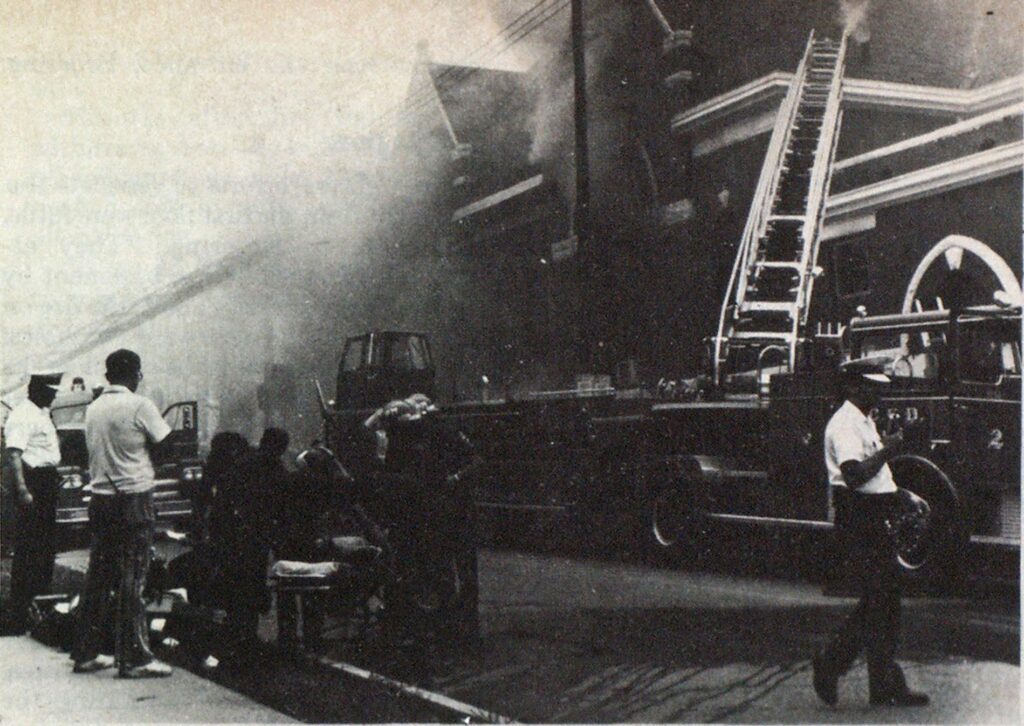

Cincinnati Church Hit by Arson Fire Just Before Sunday Services Began

Fire was discovered in a Cincinnati church last July 19 just minutes before Sunday services were to begin. Extraalarm fire companies soon had to be called to assist undermanned crews fight the $150,000 blaze. The cause of the fire has not yet been determined, but according to Fire Investigator Steve Hillman, it may be arson.

Fire officials blame the large loss of this fire on numerous structural problems which made proper ventilation of the initial basement fire impossible. And, according to Cincinnati Fire Chief Norman L. Wells, although sufficient fire apparatus responded on the first three alarms, fourth and fifth-alarm companies were called for manpower. Wells said several companies were running with only three men because of a department-wide manpower shortage that day. A class of 60 fire recruits in a 15-week training program still had two weeks to go before being assigned to companies.

The fire originated in the south side of the church basement behind a clothes rack in a choir robe room and spread up a stairway and hollow floor supports to the south center first floor.

It was discovered by a man in the basement about the same time it was also noticed by several persons on the first floor who saw it rush up interior steps on the south side of the building. At this, an usher pulled a nearby street fire alarm box at 10:32 a.m. The minister attempted to fight the fire on the stairs, but the heat and smoke drove him back.

Fire officials say the estimated 75 to 100 persons in the building when the fire was discovered were evacuated by church officials before the first-in companies arrived.

Working fire

The first-in crew on Engine 29, responding alone to the street alarm box from .8 mile away, knew it had a working fire seconds after turning the corner from the engine house. Engine 29’s Lieutenant Harold Rengering said the smoke was so heavy he could see it about four blocks away. As he arrived at the fire scene on Clark and John Strs., Rengering called in a code 2 which brought in an additional engine company, a truck company and the district marshal.

Engine 29 pulled in on the John St. (east) side of the church and laid its first line, five sections of 1 ¾ -inch hose, down an exterior stairwell to the south side of the building.

“As soon as we got down to the bottom of the steps, we saw a considerable amount of fire,” said Rengering, adding that fire fighters had to force open the locked basement door to get inside. “We took our first line directly to the seat of the fire in the basement. And it was backed up with a 2 ½ -inch line right away. With two lines, we still couldn’t hold it,” he said. “By now, it was a code 3 (called in by Captain Bernard Broering) and we were anticipating the arrival of extra companies.”

Broering, acting as district fire marshal that day, turned in the extra alarm and immediately ordered the first-arriving truck company, ladder 2, to open the roof.

Hot, humid weather compounded problems faced by fire fighters as they fought the blase. Throughout the fire, temperatures hovered around 80°F and humidity averaged about 75 percent, causing smoke to cling to the ground.

St. Luke’s Baptist Church, built in 1891, was a 60-foot-high, two-story structure with an approximately 15foot-high cupola steeple near the front center of the roof. The exterior walls were brick and the floor and framing were heavy timber. A thin wood paneling, which helped cause rapid fire spread, was used throughout the basement. A lowered ceiling, which created a plenum chamber throughout the basement, also contributed to the fire spread and its concealment. The church was 135 feet long and 75 feet wide.

Map by Captain E. Kolb, training officer. Cincinnati Fire Division

Structure problems

Structural problems which made ventilation difficult were bricked up windows throughout most of the basement; decorative plastic windows on the first floor, which were difficult to break; a double-layered first floor, covered by a thick carpeting; a crawl space on the east side of the building which appeared to be a portion of a full basement, where fire fighters ventilated, hoping to penetrate through to the basement; and a high-pitched slate roof.

“Because it was a heavy thick yellow smoke, backdraft was a possibility, Broering explained. “The fire was starting to push. The smoke was forced from the building, under pressure, because of the heat. Thev put the aerial to the first-floor landing and ventilated the roof in the rear of the building. Then they broke all the windows along the top of the building, put the aerial to the roof and opened up. They had to use a 61-foot hook ladder to hook over the roof. They opened the roof… to ventilate on the Clark St. side.”

“The first floor was ventilated as soon as possible,” said Broering, explaining that this was necessary to immediately ventilate the fire as well as to determine if the fire had extended into the first floor. “We wanted to get the smoke out immediately from the top. It was starting to build up. As soon as they opened the roof, one man began opening the plastic windows on the first floor. Later on, when the second-alarm companies came on the scene, they assisted in ventilating the rest of the windows.”

A ventilating fan was put into service on the first floor. Clark St. side, in a window near the entrance, Broering said.

Double floor

Fire fighters’ efforts to ventilate the basement from the first floor were futile. According to Broering, “They attempted to ventilate the basement by opening holes directly above the fire on the first floor. There were two holes: south side and towards the east side,” he said, estimating them to be about 3 feet by 3 feet. “We had a double floor there that we had to cut through. Fire fighters got through the floor, but there was another enclosed area (approximately 8 feet by 30 feet) underneath that we didn’t know about at the time. It was on the John St. side,” he said, explaining that because these holes penetrated only into the crawl space above the false area, they were useless in ventilating the basement.

Fire fighters also ventilated the basement by using sledgehammers to break through five windows on the Clark St. (north) side of the building which had been bricked up during remodeling.

“This was the first time I’ve run into a fire where we couldn’t get underneath … to the basement,” Broering said. “Because of the terrific amount of heat and the terrific amount of smoke, it was just a confined fire and there was no place for the heat to go. It was just like an oven. The bricked-up windows contained the heat and smoke.”

Roof ventilating procedures continued throughout the early stages of the fire. Fire fighters used the pick end of their axes to break through the slate, and gasoline-powered saws to penetrate the wood beneath.

“In the roof, the original hole on the peak (made by Ladder 2) was about 4 feet by 8 feet. The second truck company, Ladder 7, on the second alarm, ventilated the south side of the front of the building. On the third alarm, Ladder 1 opened the roof at the front section,” he said.

Ordered from building

Chief Wells pulled all fire fighters from the building when it became structurally unsound and it was evident that the fire had gotten ahead of them. From his position on Clark and John Sts.. Wells saw that the fire was burning through the roof and that the cupola steeple was about to fall. From inside the basement, Assistant Fire Chief Charles Collini radioed him that some of the rough hewn 2-inch by 18-inch floor joists had almost burned through and that the floor was beginning to sag.

“We saved what we could save—the office area, the utility area, the kitchen area. With the manpower shortage, the hot day and the advance of the fire upon arrival, it was time to pull out,” Collini said.

Minutes after fire fighters were withdrawn from the building, the steeple fell, missing Ladder 2 and Engine 14 parked side by side on Clark St. by about 10 feet.

“It would have been sitting on our tiller bucket,” commented Boering, who ordered the truck moved to a safer location after he had its ladder pipe put into service just before the collapse.

When the steeple fell, according to Collini, it caused Engine 14 to become flooded. “They (Engine 14) had a monitor nozzle set up on the steeple and when it went down, they didn’t turn the stream away and it came over and hit the pumper. They had the sides of the hood up, so it wouldn’t run hot. Water got in and knocked out the engine . . . and we didn’t have any water on that (Clark St.) side of the building.”

This didn’t affect overall fire fighting operations, Collini said. “We had other pumpers that were set around the building. We could control it (the roof fire) with the aerial streams that were set up. But for any of the fire down below (basement fire) where we might use hand lines, we were going to need the pumper. So we got some air bottles and opened the valves and blew air on the spark plugs to dry them out. I guess it was down 10 to 15 minutes.”

Water

Once fire fighters switched to an exterior attack, the demand for water increased. Fire officials say a maximum flow of 16,000 gpm for one hour and 15 minutes was used during the fire. According to Captain Tom Steidel, the water supply liaison officer, there were no major water problems. “That is a very well fed area, there is a lot of cross-gridding, cross-connecting of large mains. The system down there is designed to flow that amount. We had to fan out to hydrants in the area. When the fire broke through the roof, the demand for water increased rapidly.

“We had all the small lines being used at the early part of the fire,” Steidel said. “When we retreated and went to an exterior attack, we broke those down and replaced them with larger lines that go into heavy stream appliances and into the 2 1/2-inch line and the Stang nozzles, ladder pipes, etc.”

Fire fighters injured

Seven injuries sustained by fire fighters hampered Cincinnati’s already critically undermanned fire forces that day. The injured were treated for heat exhaustion and smoke inhalation. All were released except for one company officer who was kept in a local hospital for observation after he complained of chest pains. He was later released.

While Fire Investigator Hillman has ruled out the use of flammable liquid accelerants in the rapid spread of the fire, he has not yet found an accidental cause, either.

“We haven’t totally eliminated all accidental causes yet. There was no flammable storage down there, no garbage storage, no gas appliances, no gas pipes, no smoking down below,” he said.

Fire company records show the building was inspected last May 12 and that no violations were found at that time. Hillman, however, found illegal splicing in the wiring and other violations such as lampcord wiring substituted for no. 12 wiring and being run to an open junction box as well. These were not the type of violations which would be discovered on a routine fire inspection, he said, because they were concealed inside false ceilings.

Therefore, the fire remains under investigation.

A total of 10 engine and three ladder companies responded. Two engine companies and two ladder companies relieved original companies at the fire scene at 2:40 p.m. to finish overhauling and salvage operations. The fire was officially declared out at 5:26 p.m.