An Economical Air Trailer

FEATURES

INNOVATIONS

Photo by Steve Wolf

Sandy Fire District 72, located 25 miles southeast of Portland, OR, has a large rural population. It covers 77-square miles of varied topography — from flat lands to steep hills—and serves a population of approximately 14,500. This rocky terrain makes it necessary for us to transport empty air bottles to the main station for refilling during emergencies. As an alternative, we have developed and constructed a portable cascade system air trailer.

We determined that the system had to be:

- easily portable,

- relatively easy to use,

- economical to build.

The portability problem was easily solved by building a two-wheel trailer equipped with electric brakes. We installed Eze-Lift type hitches on both our utility pickup and brush rig. Both units also were wired for the trailer and had electric brake controls installed.

We discovered that a trailer system with the capacity we needed was going to be reasonably expensive. We investigated two commercially produced air trailers and found that their capacity did not meet our requirements, and they were also very expensive. We decided to build our own.

Photo by Steve Wolf

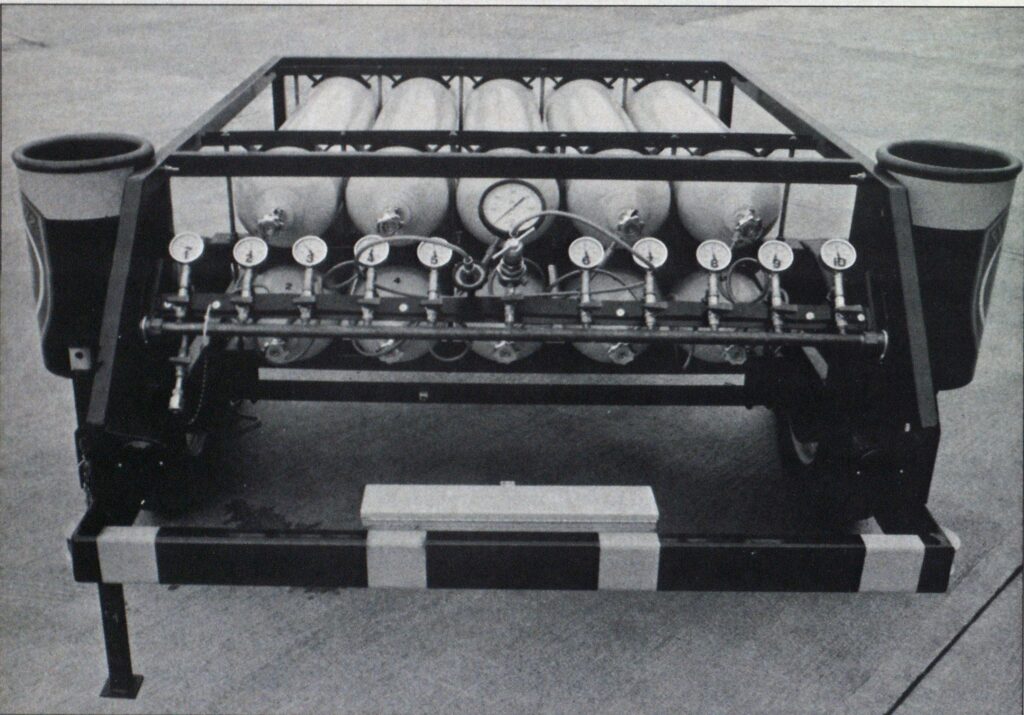

We determined that the trailer’s capacity should be in the range of 50+ bottles refilled. The bottles would start at about 500 psi and have to be filled to a maximum of 2,000 psi. After consulting with air handling companies, we decided that the trailer would have to carry ten air bottles of the 244-cubic-foot size.

Acquiring an engineered and tested manifold proved to be the hardest part of our trailer procedure. The manifold consists of a 4foot length of high-test brass pipe, which has ten 21/2-inch liquidfilled pressure gauges tapped into it. The manifold also has one 4½inch liquid-filled gauge in the center, which reads the actual pressure in the vessel being filled.

All gauges are mounted on brass tees. Directly below each tee is a stainless steel quarter-turn ball valve that makes filling air bottles easier.

The trailer was designed to carry a 3,500-pound load. It consists of a 2 X 4 X Vi6-inch wall steel frame, with 7 X 15-inch radial tires and 3,500-pound springs. The tanks are in a horizontal position and are stacked in two layers of five tanks each. They are kept in place by metal yokes that are held together with ½-inch threaded rod.

The trailer’s lighting currently comes from the towing vehicle, but the source will soon be a selfcontained 1,200-watt generator. This will allow the vehicle pulling the trailer to be used for other purposes at the scene.

For safety reasons, our filler tubes are made from 10-inch black pipe and have a 3/8-inch steel plate bottom. They are bolted, one to each side of the trailer. For safe filling practices, each tube is kept half full of water to absorb heat from cylinders being filled.

All of our paid and volunteer personnel have been trained in the safe use of the trailer and will pass the required driving test before they take it on calls. Our three neighboring (mutual aid) districts also plan to use it as a resource.

It cost about $4,500 and 75 manhours to build the trailer. This included buying ten air tanks, the manifold, trailer materials (including axle, tires, wheels, and frame), trailer lights, and paint. Upon the project’s completion, we added a 2,000-psi regulator to the filler line so that no tank could be filled above that limit. We also added an inlet on the manifold to make it easier to refill the trailer.