The Camp Vernon Burns

Quantitative research in Class A foam technology is needed to optimize the suppression equipment and methods of application. This not only wilt assist from a perspective of fireground operations and training but also will provide fire departments with evidence by which they can substantiate cost-benefit analyses.

Scientifically credible, full-scale practical suppression research on Class A foam is negligible. Anecdotal reports and preliminary tests, however, suggest that Class A foam systems and compressed-air foam systems (CAFS) may knock down up to 10 times more fire with a tenth of the water traditionally needed.

To begin credible testing, Ronald RtX’hna of the National Interagency Fire Center asked me to initiate a research effort to quantitatively evaluate and optimize Class A foam systems. Thus far, more than S130,000 in kind and S50,000 in cash have been received or committed to support this research.

PRELIMINARY BURN TESTS

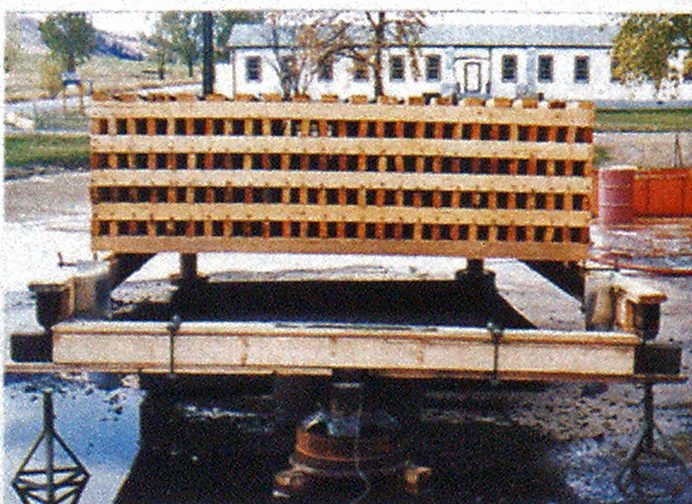

Eight preliminary burn tests of “100AB” fuel cribs were conducted at the Vernon Military Camp on October 2-17, 1992. The cribs followed the design of Underwriters Laboratories standard UL71 1 crib configuration; each consisted of 3,300 pounds of 113-inch-long 2×4 lumber.

Tlie objective was to get a rough idea of the relative flow rates of various suppression systems needed to knock down fire in identical fuel cribs. Straight streams of aspirated low-expansion foam (ALEF), loam solution, and plain water were tested. In addition, standard-pressure (100 psi) and low-pressure (50 psi) fog patterns of plain water covering the entire crib were compared.

To keep the nozzle geometry constant with various flow’ rates, an automatic nozzle, permitting the selection of either standard-pressure or low-pressure patterns, was used. For ALEF, an aspirating attachment was attached to the nozzle.

Details are published in the 1992 proceedings of the North West Fire Council.

COMPARISON OF FOAM AND PLAIN WATER

Comparison of Fires 5 and 7 (see photographs), attacked with roughly the same flow rate (202 and 228 gpm, respectively), clearly indicated the superiority of Class A ALEF. Fourteen seconds into the attack, plain water had only partially darkened Fire 5, but Class A ALEF had knocked down Fire 7, as indicated by a billow of white smoke and lack of flame showing above the crib. Only two four-inch flames are visible on the right side, which the foam couldn’t reach directly.

The plain water attack on Fire 5 was! stopped after one minute, as it was apparent that the fire, with an eight-foot flame height, would not be darkened until it ran out of fuel. It rekindled to half the crib diagonal 70 seconds after the attack ended.

It took 220 seconds tor Fire 7 to rekindle to half the crib’s diagonal width— three times longer than with plain water. Also, visibility seemed to be much better after ALEF attack than after attack with plain water.

The 10 percent higher flow rate for ALEF seemed to be more than compensated for by winds of up to about three mph blowing Fire 5 so that only about 75 percent of the crib ignited—the part closest to the nozzle. This gave plain water a considerable advantage over ALEF, so in comparison, ALEF is probably even more effective than the numbers indicate.

QUANTITATIVELY COMPARING SUPPRESSION SYSTEMS

Previous attempts to compare suppression equipment have been plagued by the problem of how to do it validly, since different flow rates and knockdown times are involved. Also, because water sometimes is short on the foreground and because water damage to a structure may be significant, any comparison should include gallons of water used.

A promising method, therefore, is to plot gallons to suppress the fire vs. gpm showing critical flow rate (CFR). This type of graph is called a knockdown curve.

The CFR method was used in this experiment. Results are plotted in the knockJown curve. Three fires were attacked ;vith ALEF. After corrected fire knockdown points were plotted in the graph, a smooth curve was drawn between the points. This was extrapolated to get the CFR of roughly 80 gpm. The significance of CFR is that unless the flow exceeds the CFR, the fire will not be knocked down until it runs out of fuel—which lowers the CFR to the point where it can be knocked down with the available flow.

KNOCKDOWN CURVE: CAMP VERNON BURNS

Time in seconds to knockdown was added to the curve, the point for a 200second knockdown being calculated.

There were two fires for plain water in straight stream, allowing a comparison with ALEF.

The effectiveness of ALEF and plain water can be compared quantitatively by calculating the ratio of the critical flow rates plotted in the graph, which is 160/80 = 2. On a preliminary basis, it appears that 80 gpm of ALEF is as effective as 160 gpm of plain water, both being applied in a straight stream.

Suppose 120 gpm is the maximum that can be applied to the fire. If plain water were used, this would be below the CFR of 160 gpm, so the fire could not be darkened even if water were applied for 10 minutes, using 1,200 gallons. Eventually, the fire would run out of tuel, lowering the CFR to below the application rate so the fire can be darkened. Of course, if the ftiel were a small single-story house, after ~ 10 minutes there would not be much left ⅛ to save.

ALEF applied at the same 120-gpm rate 4 would darken the fire with only about 150 gallons of water in about 85 seconds. If the flow rate could be doubled to 240 gpm— triple the CFR—the fire would be darkened in under 14 seconds, using only about 50 gallons of water.

Suppose only 500 gallons of water is available and the highest possible fire flow . is 150 gpm. Plain water at 150 gpm, being below the CFR, would not darken the fire and would run out after three minutes, allowing the fire to quickly rekindle to near its previous intensity. The only effect-i of suppression would be to delay the destruction by a few minutes.

If ALEF were applied at 150 gpm. though, the fire would be darkened in about 40 seconds using about 100 gallons • of water, leaving 400 gallons for overhaul or to prevent rekindle by applying it in’ short bursts until water supply is established. In this case, foam can’t be said to be only twice as effective. It is clearly infinitely more effective, since the battle against tlie fire would be won by a foam attack and lost by using plain water. Fire is a win or lose situation; 50 percent is not a pass!

The significance of the CFR is that this is the minimum flow rate needed to darken the fire. For plain water, at least 160 gpm is needed to darken the fire, while for ALEF at least 80 gpm is needed.

The media usually report fires attacked below the CFR by saying something to the effect that, “Firefighters fought the blaze for 12 hours before bringing it under control.” This really means that throughout the fire, firefighters failed to exceed the CFR. Only after 12 hours did the fire burn down to the point where the CFR was below the application rate.

FOAM SOLUTION RESULTS

Foam solution applied at 127 gpm in a 50-psi straight stream was used to attack Fire 3 for 14 seconds. It was “guesstimated” by -analyzing video records that had the stream been applied for an additional six seconds or so that knockdown would have been achieved. A corrected point therefore was plotted. It suggests that solution may be highly effective for fire attack and merits further research.

LOW-PRESSURE FOG RESULTS

Two fires were attacked with a fog pattern covering the entire crib. To cover the entire crib with a standard-pressure 100-psi fog (Fire 2), the nozzle tower had to be moved up to 13 feet from the crib. Even 324 gpm failed to darken the fire after 22 seconds. It appeared that a steady state quickly was reached in which the heat of the fire balanced the cooling effect of boiling the fine water droplets of the spray. The flame height was reduced from about 45 feet to 15 feet above the crib, but there was no sign that the fire could be darkened. Most water applied seemed to be evaporated by the overhead flame without having appreciable effect on the fire. It is expected that the major effect of cooling the overhead is to slightly reduce convection currents.

With a low-pressure 50-psi fog (Fire 1) adequate coverage of the crib could be achieved with the nozzle moved back to 16 feet from the crib. Initially, 84 gpm was applied and seen to be inadequate to darken the fire. It then was raised to 196 gpm for a few seconds. This darkened the fire to roughly the same degree as did the standard fog at 324 gpm, so plotting the points allows for a valid comparison.

The advantage of low-pressure fog may be that the larger droplets seem to penetrate the (overhead) flame and reach the fuel crib surface without evaporating fully. The fine fog of a standard fog nozzle seems to be fully evaporated by the flame above the fuel, so it doesn’t penetrate to the fuel.

With low-pressure fog, the same effectiveness seems to be achieved with less than two-thirds the flow rate of standardpressure fog. Since the nozzle reaction for, low-pressure fog is 30 percent less than that of standard fog for the same flow rate, it is apparent that research into the benefits of low-pressure fog is warranted.

LOW-PRESSURE SOLUTION FOG

A potentially useful combination suggested by the above results is a narrow spray of foam solution, since the slowermoving droplets containing surfactants are likely to wet the fuel without running off better than the higher-velocity cold’ water of a straight stream.

The advantage of the narrow spray is that it can be directed almost totally at thej fuel, not at the overhead fire, thereby saving the water that would be wasted in cooling the overhead flames. Another ad-, vantage may be less water wasted through splashing of the spray than from a straight^ stream.

CONCLUSION

Because virtually no scientifically credible full-scale fire suppression research has been done in this area, a lot of catching up is needed to help the fire service reduce” human suffering and damage to resources, the economy, and the environment through cutting fire losses by using new’ technology. It is hoped that this research project will help meet the need.

Although the results reported here are strictly preliminary, this study has demonstrated that it is feasible to quantitatively compare fire suppression equipment.

Since fire suppression is a threshold effect—either you win or you lose—increasing suppression effectiveness by even 10 percent can make the difference between saving a building and losing it. It seems likely that optimal suppression methodologies can darken three to six times as much fire as can traditional equipment at very small cost. This will drastically cut fire losses, particularly in large structures.

In future study, about 60 quarter-ton crib fires will identify and optimize the most promising direct fire suppression equipment and methods suggested by the preliminary burns. These burn trials will compare foam solution, aspirated foam, and CAFS with straight streams of plain water. Standardand low-pressure combination nozzles will be compared using narrow and full-width spray patterns. Statistical methods will be used for scientific experimental design.

Data from those burns will be used to design a subsequent burn experiment using about 20 two-ton fuel cribs. This will provide information on fire scaling so that a convenient rule similar to the “Iowa formula” can be developed to aid size-up.

Preliminary practical wildland-urban interface burn trials also will be conducted in cooperation with the Kamloops Forest Region, as resources permit. Also, given funding, preliminary structural burns will be conducted, using the most promising suppression systems identified in the crib burns.

This study was funded by Forestry Canada and the Ministry of Forests under the Canada-British Columbia Partnership Agreement on Forest Resource Development: FRDA II (1991-1995). This report has been reviewed by Forestry Canada and approved for distribution. This approval does not necessarily signify that the contents reflect the views or policies of Forestry Canada or the Ministry of Forests. ■

Endnotes

1. Colletti, D., “The Salem Tests,” Fire Engineering. February 1993, 4l.

2. Edwards, C.B., North West Fire Council Proceedings, November 1992.

3Edwards, C.B., “Critical Flow Rate,” Fire Engineering, September 1992, 97.

4. Fornell, I)., Fire Stream Management Handbook, Fire Engineering Books, 1991, 53.