BY ROBERT MAGEE

New fire officers are trained in many areas: composing memos, resolving conflicts, developing standard operating guidelines (SOGs), creating incident action plans, implementing the incident command system, and a range of other managerial functions. The training, however, may end up short on subjects such as flow calculations, risk-vs.-benefit, and other critical fireground functions for which a new first-in officer would be responsible. This article presents a method for simplifying the “math” for more practical applications in the real world where the split-second decisions officers make relative to handline selection can make or break the operation. It’s not about getting the perfect numbers for fire flows but more about becoming familiar with the engine’s handline capabilities as applied to different types of buildings. We don’t have to have the “perfect” size line for a given fire, but we certainly want our officers to have a good grasp of the lines’ limitations. This is even more critical when committing the crew on an interior attack. We also don’t want to limit a crew’s maneuverability by always choosing the largest line available when the job can be accomplished more quickly with an appropriate size line.

As much as we train our officers on mathematical calculations, it is not always easy for them to determine these values while “on the fly” responding to structural fires, especially at 0300 hours. Sizing up for flow rates and hoseline selection will usually get lost and be replaced with simpler rules like using 1¾-inch hose for residential fires and 2½-inch hose for commercial fires. Current construction practices challenge this simpler style of thinking, as we can encounter 2,000- to 10,000-square-foot, single-family homes with open living concepts and no sprinklers. Commercial buildings could be smaller than some of our residences and have better built-in fire protection!

|

| (1) For most fires, we are well aware of the size of the handline we will use. [Photo courtesy of the Millville (DE) Volunteer Fire Company.] Click to view video |

IOWA/GRIMWOOD FIRE-FLOW FORMULA BACKGROUND

Before we talk about a simpler method, we have to look back to the main flow-rate formulas we were exposed to in training. The Iowa-Grimwood Formula

|

Length × Width × Height ÷ 100 Length × Width × Height ÷ 200 |

is a formula that matches the amount of oxygen available with the support-combustion and the heat-absorbing properties of water when being converted completely to steam. The problem when trying to use this formula is that it’s based on a completely closed compartment, which is impossible for us to achieve, since we have to open at least one door. Opening the door “unseals” the compartment, and much of the steam-converted water will be carried out in thermal drafts before it would be of any good to us. The second concern is that with the newest Underwriters Laboratories (UL) studies, we know that the thermal survivability limit for civilian victims is 200˚F. A fire attack that relies heavily on steam conversion (212˚F) could endanger potential victims who have not been rescued.

|

| (2) The old adage “Larger building, larger line” still applies, but what if the fire were in the smaller waiting area? [Photo courtesy of the Millville (DE) Volunteer Fire Department.] |

NFA FORMULA AND THE ADVENT OF THE MILLVILLE FORMULA

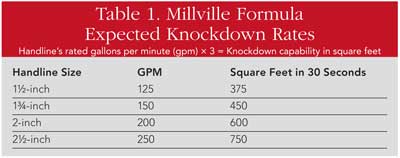

The National Fire Academy (NFA) formula (Length × Width ÷ 3 for 30-second knockdown) is more of a consensus formula; fire departments were polled and the results of needed flows were determined mathematically. This allows for more flow than the Iowa-Grimwood Formula and achieves more realistic initial flows for interior firefighting. This formula is the base used to develop the Millville Formula.

We started to think about how we could simplify the math to allow for a more rapid and more correct hoseline selection. We know that when we apply the NFA formula, we choose the smallest handline that exceeds the calculation result.

One of the problems we experienced was that some of our officers weren’t very good at judging distances, and there were very large differences in the results. We simplified the formula by changing it to Area ÷ 3. We did this because most people are constantly exposed to square footage information about buildings: “I’m looking for a 2,000-square-foot house.” “They live in a 1,200-square-foot rancher.” “The new Wal-Mart in town will be 100,000 square feet.” This change allowed for more consistent area calculations.

We then trained on typical area sizes of single-wide trailers and single-story homes. We implemented the general rule: “Greater than 50 percent involvement should be a defensive attack.” Then, we discussed typical room sizes such as 200 square feet for a bedroom, 400 square feet for master bedrooms, 600 to 900 square feet for living rooms, and so on. This helped our officers achieve a better general understanding of the types of buildings and normal rooms we would typically encounter. We were challenging them to think in “area” to better read the fire.

“Room-to-room” buildings were addressed. In these buildings, the flow rates would be less than those for a single, large, open area (the majority of single-family homes), and the maneuverability of a smaller line can be much more important than the flow rate. The formula is based on 30 seconds, but if we can advance or hold our position for a minute, we can double our knockdown capability and quadruple it if we can hold our position for two minutes. We found that even with these simplifications, it could still be a challenge to determine the proper size handline. We developed an even simpler guide by further revising the Millville Formula.

|

| (3) Training on line selection while doing the line pulls helps officers to think about which line and why. (Photo by author.) |

THE REVISED FORMULA

We reversed the math to determine our handline capabilities instead of “matching” a handline to an expected flow calculation. An engine has a limited number of choices for interior firefighting. We only have to look at the normal handline sizes we carry and teach the capabilities of each. Knowing that the NFA formula is Length × Width ÷ 3 (simplified to Area/3), all we have to do is reverse that math to determine our hoseline’s capabilities. The new Millville Formula is as follows:

Examples

A 1¾-inch handline set at 150 gpm × 3 = 450 square feet of knockdown capability.

A 2½-inch handline set at 250 gpm × 3 = 750 square feet of knockdown.

This formula is adaptable to any flow rate for any handline and can be quickly rated, taught, and understood. If your department flows a 1¾-inch handline at 180 gpm, the capability is 540 square feet.

Four-Finger Method

Working from Table 1, we can further simplify the handline capabilities by rounding the expected knockdown areas to an even number-400, 500, 600, and 700 corresponding to 1½-, 1¾-, 2, and 2½-inch handlines, respectively. This provides an officer with a quick reference for making a decision when arriving on a scene. With your thumb down, you have four fingers. The first finger is 400 (1½-inch), the next finger is 500 (1¾-inch), the next is 600 (2-inch), and the fourth is 700 (2½-inch). It’s not perfect, but it allows for a very quick and simple reference.

This formula also allows officers to make quick calculations for using multiple handlines (one 1½-inch handline @ 125 gpm = 375 square feet; two of these handlines would be 750 square feet or equal to a single 2½-inch line).

In addition, it is a tool the incident commander (IC) can use to calculate the amount of time an interior crew should be expected to take to complete the knockdown, which enables the IC to recognize that there may be hidden/unknown fire or the lack of effective advancement.

The best part about this math is that as new studies about accurate flow rates for interior firefighting are released, we will only have to change the number of our handline’s capability and can move on.

ROBERT MAGEE, a 26-year veteran of the fire service, is deputy chief and a past chief of the Millville (DE) Volunteer Fire Company. Previously, he was a member of the Ocean City Fire Department for 13 years. He served as a firefighter-paramedic, a fire instructor, and a field training officer. He is also an instructor with Strike the Box Training, LLC and has been published on the Fire Engineering Web site.

Fire Engineering Archives