Refit Pumper Saved Money, Performs Better Than Ever

features

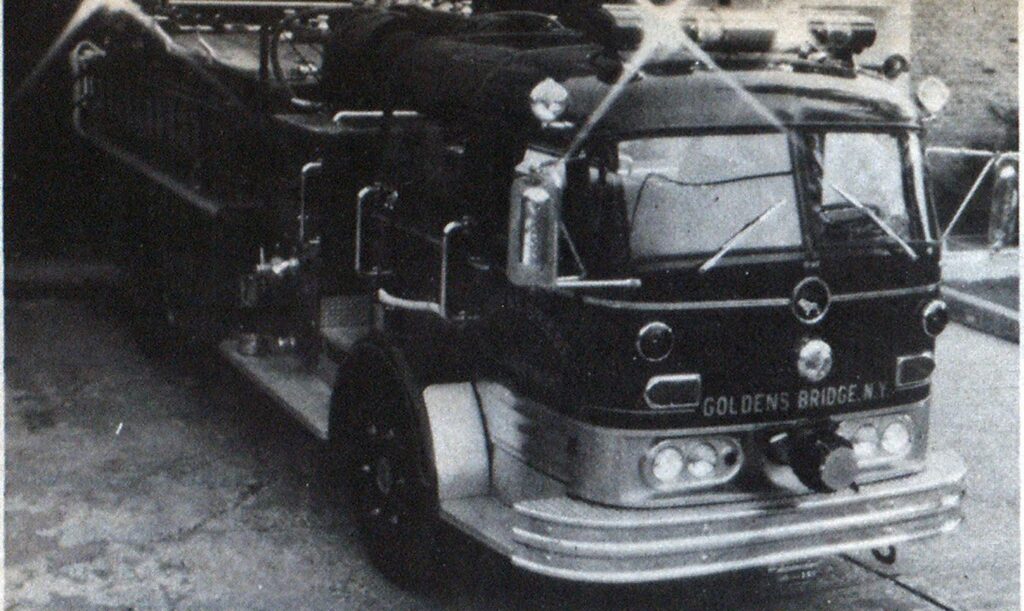

Our situation was not unique. The Golden’s Bridge, N.Y., Volunteer Fire Department needed to replace its aging and ailing class A 1000-gpm pumper truck last year. The cost of a comparable new pumper was in excess of $100,000, money our fire district simply did not have.

Today, we do have a “new” truck, but it only cost $25,000. This was accomplished by repowering and upgrading our 1965 Mack pumper. This truck now performs as well as—or better than—it did when new. It is easier to operate, safer on the road, and its remaining useful life span has doubled. After 1500 new miles, the improvements have made sense in terms of safety, pride and training—as well as dollars.

The original cost of our pumper was $42,000 in 1965. In 1980, the replacement cost of the vehicle was estimated at $115,000. We saved between $75,000 and $80,000. By retrofitting the truck, we have apparatus that performs like new at one-fourth the cost to the taxpayer.

Cracked block

After 15 years of very satisfactory service, we had significant engine problems with the Mack. We were experiencing a disturbing loss of power on the road. Overheating was severe, causing engine hoses and belts to catch fire. We were losing water. Later, inspection revealed a 6-inch hairline crack in the block. This crack was the cause of these problems.

Further, we experienced a dangerous lack of visibility on the road. Our fire district serves 2500 people in northern Westchester County in New York State. Frequently, we use interstate highways when responding to a call. But we found that our lights and sirens were not effective warnings in this congested area. Passenger cars did not see or hear us on the highway until we were right on top of them.

We decided that a repowering and upgrading of the apparatus was our only affordable alternative. Russ Con, out of West Nyack, N.Y., gave us a wellintegrated equipment retrofit. Despite our fears that remaining original equipment might not withstand the changes, we have found no problems since the repowering took place last July. I believe that a well-planned retrofit can anticipate and avoid such failures. Worn-out equipment, however, should be replaced when other equipment is being upgraded.

New engine, and more

We replaced our 1965 gasoline engine and five-speed manual transmission with an 8V-71 Detroit diesel engine and a model 644 Allison four-speed automatic transmission.

The electrical system was completely overhauled to provide adequate power for quartz lights. Our generator was replaced by a 12-volt, 100-amp, 110-volt capacity alternator with a built-in regulator along with a dual battery system with a master switch. In that process, we lost a driver’s compartment which had stored hand tools and extra quarts of oil.

We also took the opportunity to replace our corroded radiator with a new radiator. We conducted our yearly pump inspection during the retrofit and replaced valves and resurfaced as necessary. Finally, our driver seat was broken, so we replaced this with a new seat.

One of the most dramatic improvements we made was to replace our rotating warning light with a Federal Signal AeroDynic light bar and PA-20 siren. Even preoccupied interstate-highway drivers traveling at high speed now pull over to the right or stop well in advance of our truck. Both our citizens and our volunteers are much more comfortable with this new warning system.

The truck was recertified at its original capacity of 1000 gpm. In fact, the pumper exceeded certification requirements.

More improvements coming

In late 1981 or early 1982, we plan to initiate the second phase of our operation. At an additional cost of $15,000 or less, we will paint the truck and compartments and clean or replace our water tank. We plan to end up with a truck that looks like new, as well as one that feels like new.

Our repowering and refitting project saved our taxpayers an impressive amount of money. Also, there were other, less tangible benefits. Our 50-year member as well as our newest member can drive the automatic transmission with confidence. Our training program runs easier, because the fear of the ailing equipment has been eliminated. This repowered, easy-to-drive truck has boosted morale. When your men are volunteers, pride holds you together.