Reduced Manning Levels Requires Larger Size Hose

features

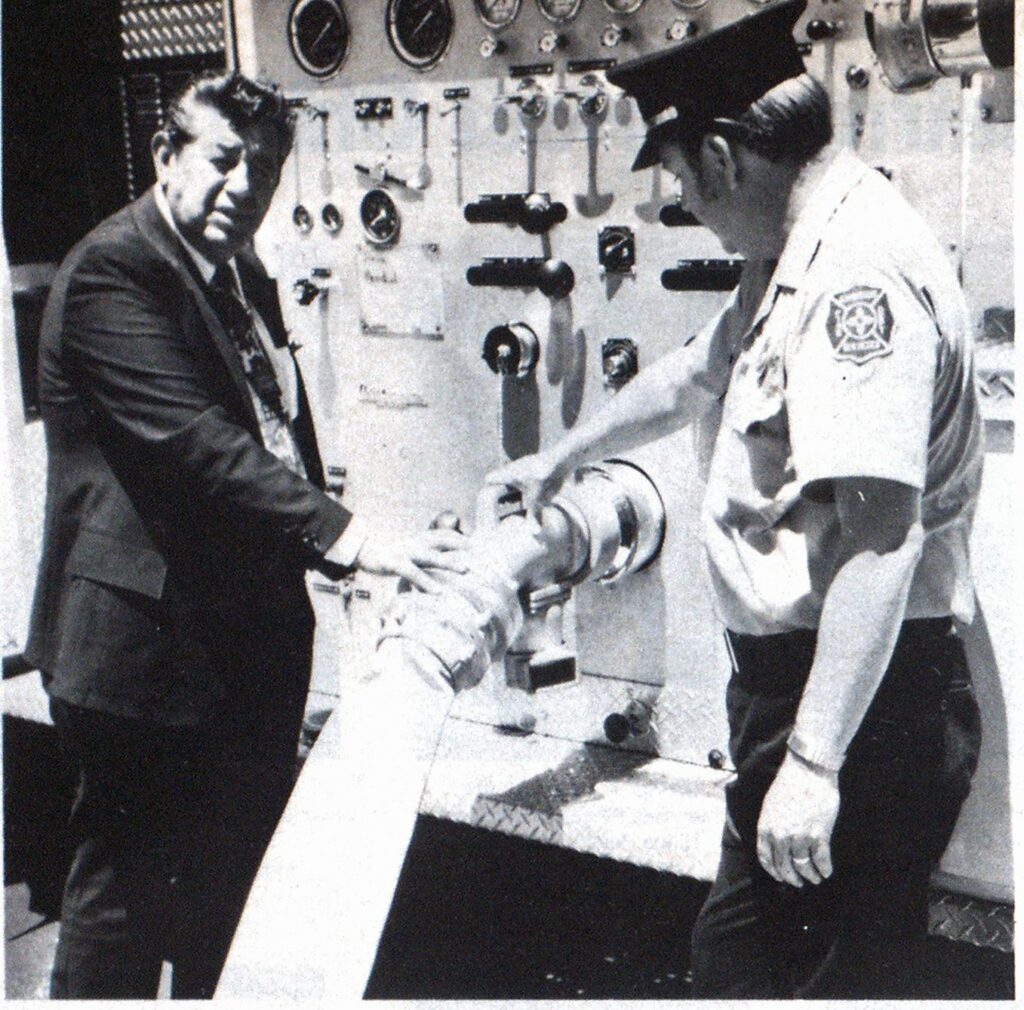

photos by Dave Windle

The continuing trend to construct large wood-frame apartment projects and office complexes throughout the nation presents a serious problem for fire fighters.

Often built with little or no automatic detection and extinguishing facilities, these structures require the rapid application of large quantities of water to halt fire spread and protect exposures. To further complicate matters, the economics of city government has forced lower manning levels on paid fire departments from coast to coast.

Like many other cities, Albuquerque has been affected to some extent by both these trends. The rapid expansion of the city from a population of approximately 35,000 in 1940 to over 320,000 today brought on a boom in apartment building during the early ’70s. A series of fires in apartment complexes under construction during that period showed the need for improved master stream capabilities in the fire department.

Although fortunate to have a modern water distribution system with adequate mains and good pressure, the Albuquerque Fire Department was limited by the fact that 2 1/2-inch hose was the largest it had.

Hose studies initiated

With these facts in mind and with the trend to lower manning with increased productivity and capability per man, Albuquerque Chief Arthur Martinez initiated studies in late 1974 to determine which size and type of large-diameter hose would be most appropriate for Albuquerque.

Captain Ross Aranda and Lieutenant Bernie Rutan were assigned to investigate the advantages and disadvantages of the various hose types and to obtain on a temporary basis samples of each for field tests. Consideration was mostly given to either conventional doublejacket 3-inch hose or to the larger diameter synthetic hose. Double-jacket hose larger than 3-inch was felt to be too heavy and bulky, considering the reduction of manpower on some companies. If synthetic hose was to be used, it was felt desirable to advance to at least 5-inch diameter.

Field tests of 3-inch hose merely verified the friction loss and flow information already available from other sources. The obvious advantage of 3inch hose was its similarity to 2 1/2-inch hose in wear and abrasion characteristics, in size (meaning that modification of hose beds would not be necessary), in the use of standard couplings, and in the relatively small increase in cost over 2 1/2-inch hose, thereby giving a much better cost-to-flow ratio.

The test of imported 5-inch hose with hermaphrodite, quarter-turn couplings was done with the same hydrant and 1000-gpm engine that were used in the 3-inch hose test.

Results of test

Three hundred feet of 5-inch hose was laid from the hydrant to the pump intake. The engine supplied three parallel 50-foot lengths of 2 ½ -inch hose to the intake manifold of an elevating platform and one 50-foot length to a deluge set. Two other inlets of the deluge set were fed from outlets on the elevating platform’s manifold. The hydrant static pressure was 120 psi.

With the basket 60 feet off the ground, a total of 2063-gpm was supplied by the two master streams. Flows were calculated from pitot gage measurements.

The impressive performance of the 5-inch hose convinced Martinez to implement a program to supply several engine companies as soon as funds would allow. In late 1975, 4000 feet of 5-inch hose was ordered, enough to equip six engines with 600 to 700 feet each.

With the decision to use 5-inch hose, the necessity to determine how best to implement its use and to develop a training program for those companies affected was realized. Rutan, one of the department members originally assigned to investigate large-diameter hose, was placed on special assignment at the Albuquerque Fire Academy and given these responsibilities. In addition to consultations with the manufacturer and several other departments using similar hose, Rutan spent two days with the Denver Fire Department observing their methods and operations.

Inline pumping capability

It was decided that the most advantageous use of the hose for Albuquerque would be as supply lines from a hydrant to an engine for inline pumping. An engine could now be located at the fire rather than at a hydrant several hundred feet distant.

With the excellent pressures available on the city’s water system, normally a minimum of 80 psi, 1000 gpm can be supplied over a distance of 900 to 1000 feet with no problem. In addition, the only two adapters needed for the 5-inch couplings were one at the hydrant and the other at the pump intake, eliminating the need for specialized Siameses or wyes. Finally, the pressure on the 5inch hose can he kept to much lower values than if it were fed from a pump discharge some distance from the fire.

For laying the hose, the use of a flat hose load with the line being payed out over a 20-foot rubber mat attached to the rear of the hose bed was found to be most satisfactory. This provides reasonable protection to the aluminum couplings as long as hose-laying speed is kept at about 5 mph.

A hose load of 600 to 700 feet per engine was selected. This was felt to be adequate for most locations where large quantities of water would be needed, yet it still allowed 1000 feet of 2 ½ -inch hose to be carried after the hose bed divider was moved to accommodate the 5-inch hose.

Hydrant man takes radio

Because the department had no large-diameter hose clamps, how to notify the hydrant man to open the hydrant required some discussion. The method selected was for the officer to leave his portable radio with the hydrant man. This has the disadvantage of leaving the officer without a radio until the hydrant man reaches the fire, but it gives reliable communications that prevent the charging of an unsecured line.

Concurrent with the preparations for using 5-inch hose, the department purchased four permanent-mount monitors for engines that would carry the largediameter line. These monitors were equipped with automatic nozzles and also straight tips.

The initial shipment of 5-inch hose was received in early 1976 and was phased into service on six engines. All six companies were trained and equipped in late spring, 1976.

Shortly after the first hose was in use, it was decided to equip each engine with a pump inlet relief valve. This was a precautionary measure to prevent damage to the hose by water hammer or buildup of air pressure in the line when the hydrant is first opened. These valves are set to dump water at a pressure of approximately 150 psi, since pressure on the city mains is as high as 125 psi in some areas. The relief valve also has a manually operated bleeder for releasing trapped air.

Large hose gets fire test

Although the 5-inch hose was used at several working fires, it was February 1977 before it was first used at a serious fire. This was the fire at the International House Apartments as reported in the December 1977 Fire Engineering. As reported in the article, the 5-inch hose met all expectations.

With the advantages of the largediameter hose fully verified in actual usage, Martinez decided that conversion of the entire department was justified. In February of 1977, an order was placed for 10,000 feet of 5-inch hose, enough to equip the remaining 12 engine companies plus the department’s reserve engines. Last February 1, the equipping of all units was completed.

In Albuquerque, use of 5-inch hose is not restricted to multiple-alarm fires but can be used at the discretion of a company officer. At any fire where any doubt exists as to the ability of a single 2 1/2 -inch supply line to provide enough water, officers are encouraged to lay the large hose. As pointed out by the chief, it is certainly much easier to reduce to a smaller line if a large water flow is needed than to attempt to increase water flow after commitment to a small supply line.

Advantages cited

A number of significant advantages have been gained by the Albuquerque Fire Department in converting to 5-inch hose. Foremost is the considerable increase in water available per engine at a fire scene. A single 5-inch line has approximately the same friction loss as six parallel 2 1/2-inch lines. At a flow of 1000 gpm, a loss of less than 7 psi per 100 feet is experienced with the 5-inch hose.

Even using a standard pump hookup with the engine located at the hydrant, four 2 1/2-inch lines would be required to provide 1000 gpm at increased pressure. For a typical lay of 500 feet, this would require more hose than was previously carried on a single Albuquerque engine.

Perhaps even more important is that large quantities of water are available immediately without waiting for additional engines or hose wagons to lay extra lines. With piped-in monitors or preconnected deluge sets, an engine can easily deliver 1000 gpm on the fire within 30 to 60 seconds after arrival. Such a quick hit by the first-arriving engine can often halt fire spread and hold a potentially serious fire to a single-alarm response with the existing manpower.

More efficient operations

By using inline pumping at major fires, large-diameter hose also provides more efficient operations by keeping apparatus close to the fire and allowing the apparatus driver a more active role in operations. Once the supply line is connected and the pump is in operation, the driver may operate the monitor in an initial attack while the remaining crew is extending hand lines or performing other duties.

At fires where a master stream device is not needed, multiple hand lines can be quickly extended from the first-arriving engines without the need for other incoming units to stretch hose, making for a faster attack. In addition, more 2 1/2-inch hose is now available for hand line use on each engine, even though the 2 1/2-inch load has been reduced, since none of it must be used for supply lines.

The location of engines close to the fire results in lower pump pressures for supplying ladder pipes and hand lines since friction loss in long lays of 2 1/2-inch hose from a pump at a hydrant does not have to be overcome. An engine being supplied through 500 feet of 5-inch hose and supplying the Siamese through three parallel 50-foot lengths of 2 1/2-inch hose would operate at an engine pressure of only 165 psi.

Less work with big hose

Unlike some new equipment, acceptance of 5-inch hose by Albuquerque fire fighters has been good. The all-synthetic construction eliminates the need for drying, so the hose is simply washed after use to remove dirt and foreign particles and then reloaded wet. A large amount of effort in drying and storing hose is therefore eliminated.

In addition, much less time and effort is required to pick up a single 5-inch line compared to multiple 2 1/2-inch lines. A single 100-foot section of 5-inch hose weighs 105 pounds with couplings, not much more than 100 feet of coupled 2 1/2-inch hose. Apparatus is therefore back in service sooner.

Only one disadvantage has yet been encountered with 5-inch hose in Albuquerque. Its size and weight when charged makes moving it impossible and crossing it difficult. Care must be exercised that it is laid on the same side of the street as the hydrant with the least possible obstruction to access of incoming apparatus. This is stressed in training and as yet has not been a particular problem at any fire in Albuquerque.