Pumpers Are Retrofitted For Preconnected Lines

JOHN BRASKO

Battalion Chief

and

PETER PRAY

Chief Engineer Independent Fire Co. No. I Maple Shade, N.J.

The officers of Independent Fire Co. No. 1 realized that the recurring manpower problems that faced the department called for equipment and procedure changes. One of the equipment changes called for the addition of 1¾ inch preconnected attack lines. The department’s engineers undertook the design and installation of the system.

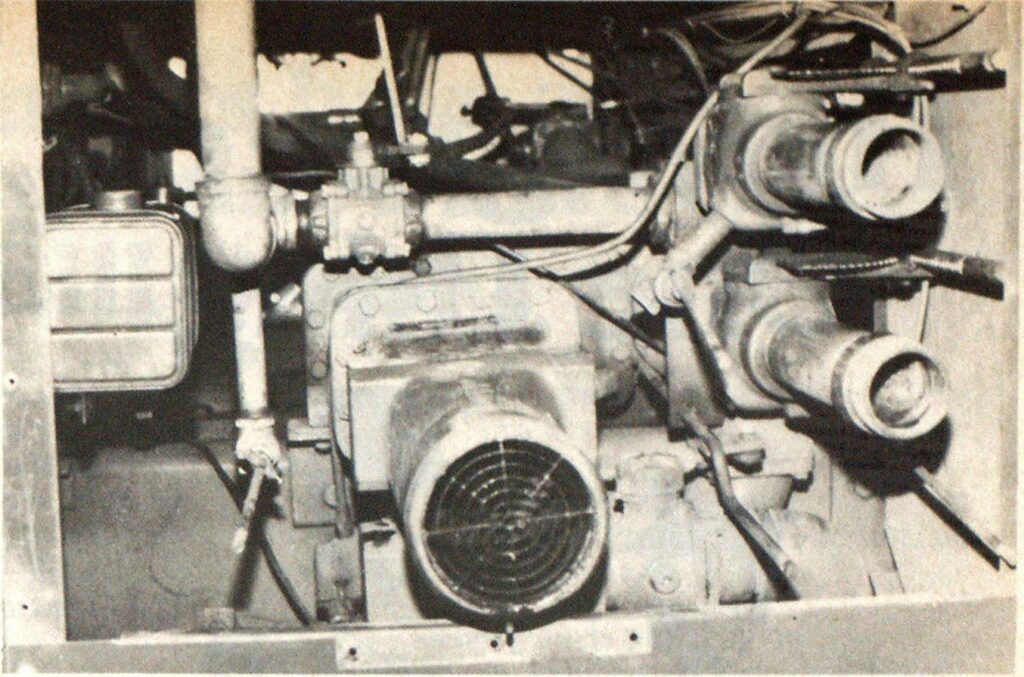

Each pump manifold had extra discharges which, when unplugged, were used to supply the water for the preconnects. Gages, ball valves and snubber valves were obtained from the apparatus manufacturer. Pipe, tubing, and fittings were purchased at a local hardware store. Other parts were scrounged from the firehouse.

Pumpers out of service

The pumpers were, in turn, taken out of service and the curbside pump panel was taken off. The pipe plug from the appropriate unused discharge was removed. Holes were drilled in the floor of the booster reel compartment and in the front of the hose bed to accommodate the piping. Pipe was then cut and threaded to run from the pump to the hose bed. Ball valves, the drain, and copper tubing to the gage completed this part of the installation.

The gage and snubber valve, as well as the ball valve control rod, were placed in appropriate holes cut in the main pump panel. Labels, also from the manufacturer, were added to the pump panel to identify the controls and the gage.

An adapter, pipe thread to fire department thread, was placed on the end of the discharge pipe for the connection of the hose. A hose body divider was made to form a separate compartment for the preconnect hose.

Hose load switch

Finally, a microswitch with one set of contacts normally open and the other normally closed was placed flush in the floor of the hose hed under where the preconnected hose rests. This switch was wired to a pair of pilot lights (one red and one green) placed on the pump panel under the preconnect discharge handle. The switch was wired with the normally open side to the green light and the normally closed side to the red light. This system shows the pump operator when the hose has cleared the hose bed by changing the light from red to green.

Hose was packed in a flat load. The arrangement that works best for us is to pack the first two folds, then place a hose strap across the load and finish the remainder of the line. The hose strap is secured around the hose and the nozzle. This allows one man to pull the hose load into the street. After unhooking the hose strap, the hose flakes out as he pulls the nozzle and first few folds.

We have found that this homemade preconnect system increases our speed and efficiency at a fire with low cost and simple installation.