Jaws Fracture Fused Mass Of Lexan Bottles Over Fire

features

Training Officer Wyckoff, N.J., Fire Department

A warehouse fire that converted thousands of plastic milk bottles into a hard mass covering remaining fire resulted in an unusual application of rescue and extrication equipment.

The Wyckoff, N.J., Fire Department responded to an alarm from the Garden State Farms warehouse on Braen Avenue at 7:37 p.m. Sunday, Oct. 7, with six pumpers, an aerial ladder and an emergency truck. A working fire was found in the interior of the warehouse with a heavy smoke condition. While 3-inch hydrant supply lines were being laid, pumpers connected, and an aerial ladder set up, an initial interior attack was made with two 1 1/2-inch lines from Engine 235, a 1000-gpm attack pumper that was first due in this area.

The initial attack lines darkened the fire and roof ventilation by the truck company diminished the smoke to a level where a better size-up of the situation could be made.

Fire under plastic mass

It was found that the fire area in the only portion of the warehouse not sprinklered, contained hundreds of plastic bags filled with several thousand plastic milk bottles made of Lexan, a polycarbonate. The seat of the fire was in an open bale of hay in the center of the bottle pile. The plastic bottles had softened, collapsed and fused from the heat. Visible fire continued in the center of the fused plastic mass.

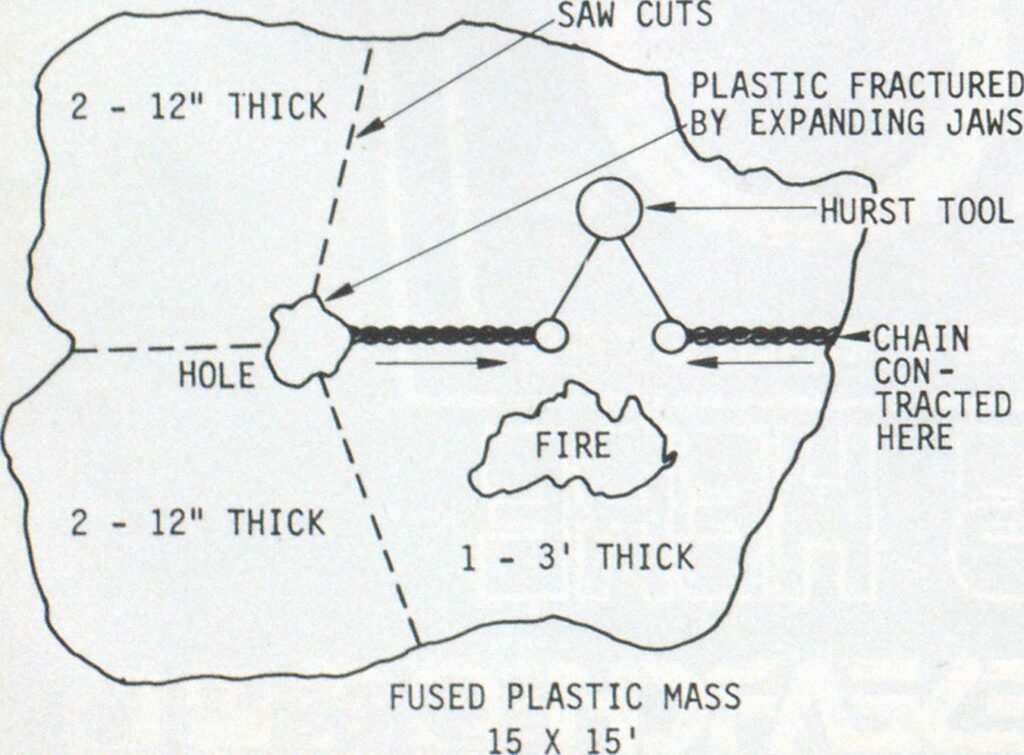

Therein was the problem. The melted and fused plastic mass covered an area approximately 15 X 15 feet with a depth ranging from 2 inches to 3 feet. The major portion of the area was at the 3-foot depth. Efforts were made to pry the mass from the floor. These resulted only in broken pike poles and frustration when other prying tools were tried unsuccessfully.

Chains used with jaws

There was an unfused hole in the plastic mass about 3 feet from one edge, so a decision was made by the deputy chief in charge to try unconventional means of breaking up the mass with emergency truck extrication equipment. A Partner K-12 saw made three cuts radially from the center hole to divide the mass into two small segments and one large segment. The jaws of a Hurst Tool were placed in the hole and expanded, causing the rupture of the plastic mass along the saw-cut lines and making it possible to remove the two small segments from the structure.

The largest and heaviest segment (which still had fire beneath it) was attacked by using the Hurst Tool with its chains. They were attached across the segment and the tool was operated to pull the chains together. The result was a further fracture of the segment into pieces small enough to be moved so that the remaining fire could be extinguished.

This action demonstrated another use for the Hurst Tool and Chief Russell Blum praised the ingenuity of the department personnel.

Since all of the equipment of this volunteer department was committed at the scene, the Northwest Bergen Mutual Aid Control Center dispatched one pumper each from adjacent Waldwick and Franklin Lakes to fill in the houses of Wyckoff Companies 1 and 3. Also under the plan, the Midland Park air cascade trailer was used to refill breathing apparatus cylinders while the remainder of the Midland Park department was standing by in quarters, covering the area served by Wyckoff Company 2.