There is no perfect size fire attack hoseline for all fires—there just isn’t! There is no “one size fits all,” either. Otherwise, I’m sure we would have found it by now and someone would have claimed credit for it.

While still on the job, I was assigned to conduct an engine company operations class for all engines on all shifts, including battalion chiefs. In each block of instruction, we reviewed department standard operating procedures (SOPs) and then flowed the three sizes of attack handlines (13⁄4, two, and 21⁄2 inch) found on engines. A flowmeter was used to verify flow differences in each size of hoseline while also going over nozzle mechanics. (Note: Nozzle mechanics are the methods firefighters use to control a nozzle while attacking a fire. In many cases, improper mechanics can lead to poor control and inferior flows during attack.) Then we conducted a simulated offensive fire attack pairing two engine companies on a 21⁄2-inch handline through the hose maze.

RELATED FIREFIGHTER TRAINING

The Two-Inch Attack Hose: The Middle Child (Always Misunderstood)

When it came to the two-inch hose, it was generally found that flows were way under what was expected—or promised years earlier. Most of the two-inch hose in the department at that time was between 10 and 15 years old. Higher pressure automatic nozzles were assigned to the two-inch lines departmentwide. The nozzles were old and not well maintained. Using the department’s SOP-mandated pump pressure of 125 pounds per square inch (psi) and pumping through a 200-foot hose layout, some of the older two-inch hose flowed in the neighborhood of 135 gallons per minute (gpm). Obviously, the question arose, why have two-inch hose when that is all it flows? (Note: This flow is easily beaten by 13⁄4-inch hose using a solid bore 15⁄16-inch nozzle or a 175-gpm constant-gallonage 50-psi low-pressure fog nozzle. If your department uses automatic or other higher pressure fog nozzles, then a regular nozzle maintenance program is a necessity. Low-pressure fog nozzles, solid bore nozzles, or break-apart style nozzles are worth researching and investing in.)

(1) Two-inch hose with 11⁄2-inch couplings and a solid bore nozzle with a 11⁄16-inch tip is simple and dependable. Flows will be in the range of 240 to 260 gpm. Low-pressure 250-gpm/50-psi fog nozzles are also available. Remember, it takes gpm to overwhelm and extinguish a fire—not high pressure and a lesser volume of water. As William Clark wrote years ago in his book Firefighting Principles and Practices, every fire has a critical flow rate. This new technology allows firefighters to deliver more water effectively. (Photos by Jeff Diederich.)

(2) Long and short barrels are available.

Since those times, hose, nozzle research, field testing, and development have taken place across the country and have given the fire service better equipment and more data, resulting in better attack capabilities than before. Research for hoselines and nozzles has led to newer materials, manufacturing, and testing, leading to greater flows and better hose manageability—and, of course, having firefighters train with this equipment on a regular basis has paid big dividends in firefighter attack capabilities.

Several years ago, Jerry Herbst of Elkhart Brass Co. and I discussed the introduction of a newer solid bore tip size aimed at better flows for two-inch hose—the 11⁄6-inch tip. This tip size beats down the old hydraulic rules where solid tip sizes should not exceed one-half of hose diameters. The 11⁄16-inch tip and modern two-inch hose is a superb marriage to some of the newer two-inch hose of today.

A point we realized is that we have been pushing a systems approach for attack hoselines and nozzles, which is best for any fire department and their firefighters. Why? Because it produces greater flows, better manageability of the nozzle, and easier hoseline mobility. It’s just that simple. The other part of the systems approach is that it is a low-pressure, high-volume attack package, which allows firefighters to flow big, even with minimal fireground staffing, which, sadly, is the rule rather than the exception for most fire departments.

The systems approach matches hoselines constructed of certain materials that allow a greater volume of water to flow more easily through the hoselines at reduced friction losses and not create a severe reaction force. Paired with a low-pressure nozzle, attack crew firefighters can flow more water and be more effective at extinguishment with a hoseline that is easily controlled.

(3) Some of the two-inch hose and nozzles tested at a Cleveland-area suburban fire department. Considerations were bend radius and resistance to kink along with the potential for nozzle whip. A well-matched attack hose system needs a good, high-volume nozzle valve and increased tip size (or high-volume/low-pressure fog tip). This prop simulated a doorway opening of a certain width to check for hose kinking when being moved through.

(4) Here, Jerry Knapp of Strategic Fire Training uses a pitot tube to measure a solid stream’s pressure during hands-on training at FDIC International 2021. Note the gauge placement behind the nozzle and the pitot tube reading taken at the nozzle tip. The pressure and orifice are then compared to a chart and referred to the flowmeter for flow volume. Friction loss is determined in the hoseline between the pump outlet and the gauge behind the nozzle. These numbers are approximate values as age, quality, material of the liner construction, any internal damage, and couplings impact flow and turbulence.

Recent Flows and Findings

While I was doing research and flow studies with a small group of firefighters from local fire departments in my area, Jeff Diederich, a lieutenant with the Bedford (OH) Fire Department, expressed concern about his department’s initial operations from standpipes in taller buildings with low initial staffing. Another of his concerns was standardization and minimum attack flows for his department and the other fire departments in the area. Understandably, his issues are echoed by many departments across the country.

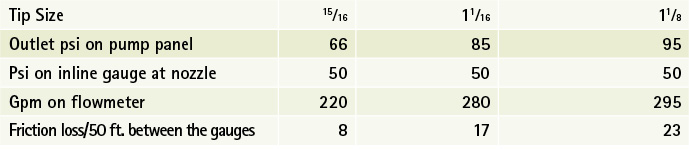

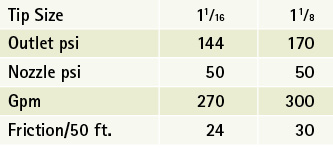

During our flow tests, a plan was devised to get good data on hose, nozzles, and flows so informed decisions could be made regarding which hose (and materials) performed best with flows and manageability of two-inch hose. A flowmeter was attached to a side discharge of an engine pump. Right after the flowmeter tube, a 21⁄2-inch inline gauge was also installed. Another inline gauge was installed behind the nozzle ball valve shut-off. The nozzle was pressurized to approximately 50 psi and then we pitoted the stream to verify the flow rate. Below are some of the findings using two 50-foot lengths (100 feet) of two-inch hose with 1½-inch couplings.

There will be approximately five to eight pounds more pressure between the back of the nozzle and the tip of the nozzle where the pitot tube measurement takes place. This is another area of discussion and understanding. Without a flowmeter or a reliable pitot tube measurement, you are dealing in approximate ranges. If you are using a combination nozzle, your only way to verify the flow is with a flowmeter. Know your flow!

(5) Two-inch hose with a 11⁄16-inch tip flowing at approximately 50 psi.

A Simple Comparison

Back in the 1970s and 1980s, there was a push to eliminate 21⁄2-inch attack hoselines in favor of using two-inch hose for big line operations. During our flow testing, we discussed the flow and friction loss properties of two-inch hose, specifically, why it should not replace the 21⁄2-inch hose, especially for heavy fire operations or when long hose stretches are necessary. To prove our point, we used 200 feet of two-inch hose with 11⁄2-inch couplings and flowed through two different solid tip sizes. To attain the flow rate of a 21⁄2-inch hose, the pump pressure was at least two to three times that of an equal length of 21⁄2-inch hose. When you have a need for two-inch hose beyond 250 feet, it should be supplied by a 21⁄2-inch hoseline. Some fire departments have already been doing this or are now using two-inch hose as a lead length on their standpipe attack hoseline kits. Below are some of the findings when we pumped a two-inch hose to match the 21⁄2-inch flows to demonstrate the friction loss differences.

In June 2015, I presented the three sizes of attack handlines at a conference. In our area of engine operations-fire attack training, there were three sections; one dealt with flows of different sizes of attack handlines using low-pressure nozzles. When the two-inch hose with solid bore nozzle was being demonstrated, the results were very much consistent as they were back home. (Before the conference, I had the same two-inch hose and nozzles shipped to the venue.) The intent was to check quality of pumps and flows of the same hose and nozzles at a venue across the country. Following were the results:

- 100 feet: two 50-foot lengths of two-inch hose.

- Couplings: ١½-inch thread size.

- Nozzles: same with split ball valve and 13⁄8-inch waterway.

- Tip sizes: solid bore one-inch, ١١⁄١٦-inch, 11⁄8-inch.

- Pump discharge pressure: approximately 90 to 95 psi (50-psi nozzle pressure plus 20-psi flow/50-foot length of hose).

- Flow results: one-inch—260 gpm; 11⁄16-inch—280 gpm; 11⁄8-inch—297 gpm.

When looking at the results of flow testing and seeing the higher volumes achieved, you may ask, why keep 21⁄2-inch hose then? It was agreed that the backpressure in the nozzle was starting to build to a point that was not acceptable. This is because as flow volume increases, so does the need for pressure to “push” that higher volume through the hoseline. We were made aware of fire departments taking old two-inch hose and putting solid tip nozzles on with 11⁄8-inch tips and then increasing pressure to obtain higher flows. This is not the intent of a low-pressure/high-volume system, nor is it a safe procedure.

As I mentioned earlier, the newer standards that apply to the materials, manufacture, and testing of our hoses and nozzles are mostly what is allowing for better flows and manageability. In the far distant past, when many of the old mathematical formulas were developed, there was one kind of material for hose lining—rubber! Hose jackets were cotton or Dacron. So, the formulas were based on those materials.

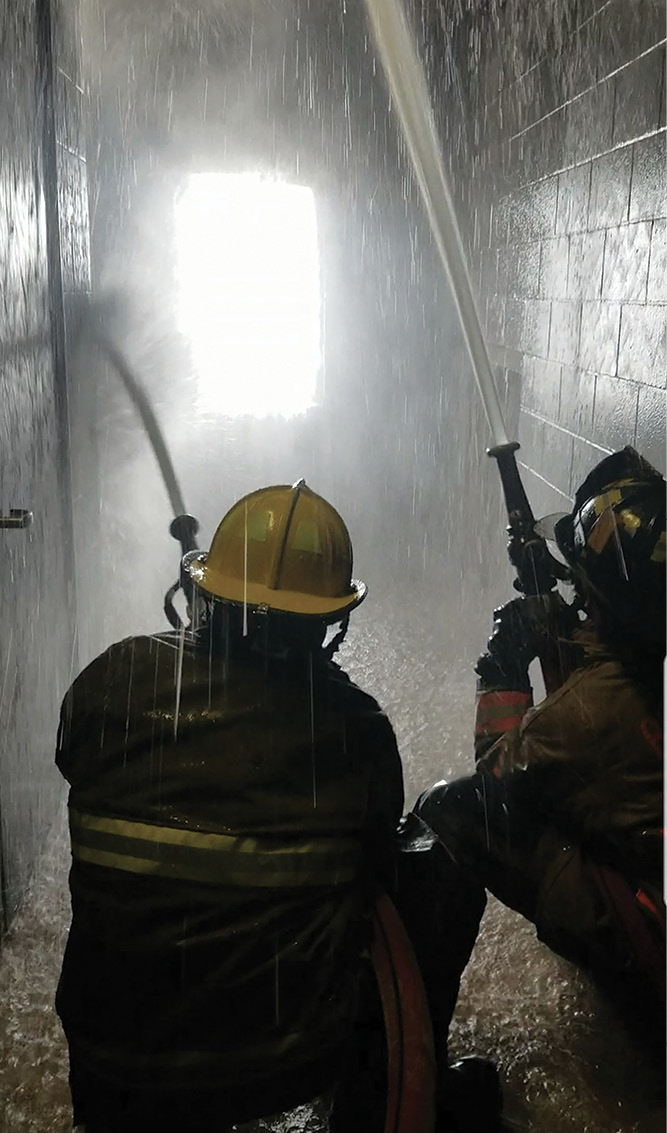

(6) Good nozzle mechanics are demonstrated with this two-inch line. The nozzle tip used is a San Francisco-style long barrel. Stream quality is very good, and volume is approximately 280 gpm. At a minimum, a second firefighter should always be with the nozzle firefighter to provide support on the line.

(7) Students operate two 150-foot-long two-inch hoselines with 11⁄16-inch solid tips. These two hoselines were supplied from a gated wye from a standpipe.

Today, we have several types of materials used for inner hose linings, and some of those allow greater flows because of low friction loss. Other factors are the hoses’ ability to expand and carry more water. Couplings, nozzle valves, and nozzle tips have all been reworked and machined for better flows.

Two-Inch Attack Lines and Capabilities

This is an intermediate size line and should not be considered as a replacement for 2½-inch attack lines. The two-inch hose is an excellent size attack line for immediate large flow from an engine water/booster tank or perhaps a tanker-pumper. It can provide for heavy knockdown and ease of mobility and advancement into a structure if that’s what conditions call for. Just remember, it can take a water tank down quickly, so initial water supply may be a concern. Remember, a properly equipped and pumped two-inch hose will flow in the low range of the 2½-inch line. Its use in standpipe operations has been realized as an entire two-inch attack line from the outlet to the nozzle or as the “lead 50-foot length” supplied by 2½-inch hoseline from the outlet.

In October 2021, the training company Strategic Fire Training conducted a hands-on training class for standpipe operations. Students were able to deploy and operate four 150-foot-long two-inch standpipe lines in the upper floors of an eight-story training structure with a total flow of just under 1,000 gpm. Each line (with 11⁄2-inch couplings) was equipped with the same style nozzle ball valve along with a 11⁄16-inch solid tip. There were two lines stretched from the fifth-floor outlet, connected to a wye on the standpipe outlet, which also had a flowmeter connected to it. Two lines were connected to the sixth-floor outlet from a wye also.

Like any attack hoseline, there need to be set “target flows” that give a particular size line its identification and capabilities. Even though we have consistently flowed between 240 and 260 gpm, two-inch hose should have a target flow of approximately 230 gpm as a minimum. This figure is what our group agreed on considering flowing pressures, manageability, and looking at the 13⁄4-inch (150 gpm target flow) and 21⁄2-inch (250 gpm target flow) lines. Each fire department should test and flow its own equipment, as results will vary from department to department.

Why 1½-Inch Couplings?

Generally, there are two sizes of couplings used for two-inch hose: 11⁄2-inch and 21⁄2-inch. It is interesting to note that coupling sizes have been a concern for some people because of a belief that there is an easier flow of the water and less turbulence through the larger coupling—for only a few gpm, but it is just an opinion and can vary per the type of material and other things mentioned before.

To illustrate a point, here is a lesser size hoseline than a 21⁄2-inch that has the capability to flow in the low-end range of a 21⁄2-inch hoseline. It is also interesting that as we are talking about a hoseline that can flow a great volume of water but is less bulky and very maneuverable, a 21⁄2-inch coupling is considered, which creates just that—more weight and bulk.

The bottom line is that 11⁄2-inch couplings are the most efficient size couplings for two-inch hose. They are universal in that the 11⁄2-inch couplings can be connected directly to an engine outlet with 1½-inch threads, to a wye, to a wye connected to a standpipe outlet, or directly to a 21⁄2-inch nozzle valve after removing the tips. The two-inch hose will get all the water necessary through that size coupling or adapter (from 21⁄2-inch to 11⁄2-inch).

The 21⁄2-inch couplings are obviously bigger, bulkier, and heavier than 11⁄2-inch couplings. They also have a greater tendency to catch on a door sill or get caught on corners or furniture while being advanced.

The most important thing to know about hose couplings is that 11⁄2-inch couplings have a waterway of 13⁄8 inches! A 21⁄2-inch nozzle ball valve has a waterway of 13⁄8 inches! So, the ability to flow is there regardless of coupling size. It may come down to personal preference.

Lessons Learned/Reinforced

- Low-pressure, high-volume fire attack systems are winning favor in fire departments across the country. They work well with all size hoselines.

- Two-inch hose is an excellent intermediate size attack hoseline, especially when outfitted with 11⁄2-inch couplings and low-pressure nozzles. It provides much more fire power than 13⁄4-inch attack hoselines and only weighs approximately 15 pounds more per 50-foot length when filled with water, allowing good mobility and control.

- Two-inch hose should never have been considered as a line to replace 21⁄2-inch attack hose because it does not have the “kill power” of the 21⁄2, the “king of hoselines.”

- There are only two kinds of fire service hydraulics—one of those is seen in promotional exams. The other is the kind that you will use most often in your career—street hydraulics. That’s where you may find yourself under stress supplying water to attack lines, trying to figure out numbers. It’s all about simplicity!

- Don’t expect to see absolute accurate numbers. In the past, some old “drillmasters” would pull out an old hydraulic formula and quiz you on it to see if you knew exactly what you were pumping. That was the preflowmeter era. Many people now realize we are looking for approximates or “target flows,” which are the minimum gpm that a particular size hoseline should be flowing; however, we should always work to beat that!

- When it comes to pumping into attack hoselines, you shouldn’t underpump or overpump. Nozzles are designed to operate at their best using certain set pressures. Pumping higher or lower into the lines creates lower volumes or higher reaction pressures.

- If your department wants to consider a low-pressure/high-volume attack system, you should first discuss and develop a plan to find what you are looking for. For example, do you want greater flows and hoseline mobility? What about engine company staffing? What are your personnel availability and initial stretching considerations? A quick hit or blitz line with move-in capabilities?

- Consult others with knowledge and experience with two-inch hose systems first, and then conduct your own research and field testing. Assemble your data; what you find should be used for the purchase and implementation. Present the equipment and train your people in its use; then, monitor its use.

- Firefighting is all about principles and practices.

JEFF SHUPE is a division chief (ret.) with the North Myrtle Beach (SC) Fire Department and a firefighter (ret.) with the Cleveland (OH) Fire Department with 47 years of service. He has an AS from the University of Cincinnati in fire protection engineering.

Jeff Shupe will present “The Engine Company: Effective Fire Attack” on Monday, April 25, and Tuesday, April 26, 8:00 a.m.-5:00 p.m., and “The Engine Company: Firefighting in Contemporary Times” on Wednesday, April 27, 3:30 p.m.-5:15 p.m., at FDIC International 2022 in Indianapolis.