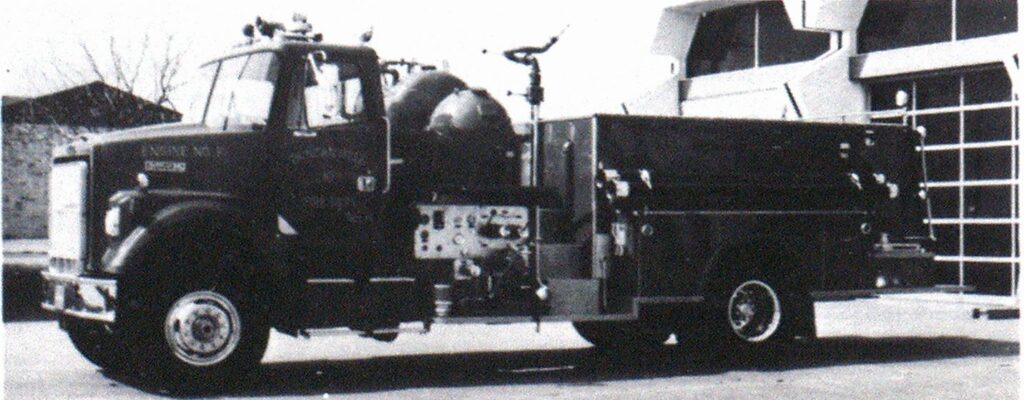

Excess City Chassis Used To Build New Texas Pumper

FEATURES

Refurbishing fire engines is a current trend because of the economic situation. We went one step more and built ours from a garbage packer chassis with the assistance of fire fighters, other taxpayers and businessmen. We have an engine that we’re proud of, and we saved up to $90,000.

When the City of Duncanville, Texas, purchased a 1979 Autocar chassis from the White Motor Corp. to be made into a garbage packer, it did not anticipate going out of the trash collection business. But in 1979 the city put trash collection out on contract and wondered what to do with the new chassis.

Lt. Emil Stewart suggested to Fire Chief Robert S. O’Burke that the fire department could build a fire engine out of it. O’Burke took the request to the city manager and city council. They approved the request, and the chassis was turned over to the fire department.

Installed pump

The department had an old General engine that was beyong ISO acceptance but still had a good 750-gpm pump. This was to be the start of the new engine. B shift at Central Fire Station started the preliminary engineering to install the pump. A special water tank had to be designed to hold the extra water desired by the department.

Construction began with the help and cooperation of several local manufacturing companies and individuals. Universal Manufacturing of Duncanville did all the metal breaking for the tank and compartments. The chrome plating was donated by Best Plating of Hutchins, Master Plating of Duncanville, and U.S. Plating of Dallas. The entire paint job was donated by Bob Hayes Chevrolet. White Motor Corporation donated an external tachometer, chrome hubcaps and lug nuts. Fibre Trend of Duncanville built and donated a 25-gallon fiberglass foam tank. Stewart Backhoe Service donated specialty tools. In all, local businesses donated about $6000 worth of parts and services.

Minimum cost

The City of Duncanville expenditures were about $48,200 for the entire unit. Through donations to the department and the fire fighters providing all the labor, the cost was kept to a minimum. The cost of a new unit of this type would be between $100,000 and $140,000.

The project was started in July of last year and completed Jan. 28. The engine carries more water than usual—about 1376 gallons. The engine has a 3-inch deck gun plumbed into the pump. It can deliver 700 gpm. Also, a 25-gallon foam tank is built into the system and is connected to an in-line proportioner and 150 feet of 1 1/2-inch hose. It has a selfcontained unit of 100 gallons of AFFF and 450 pounds of dry chemical.

When the engine was completed, the fire fighters throught it was as near perfect as possible. An old friend of the department, Lefty Lumpkin, had driven Engine 10 for the Dallas Fire Department, so we gave our new engine the number 10.