Breathing Apparatus Safety System Includes Lab Tests and Inspections

features

To minimize the odds of mechanical failure of self-contained breathing apparatus, the Frankfurt Fire Department in West Germany provides its 800 paid and 900 volunteer fire fighters with a unique safety control program.

Fire fighter safety is the most important consideration of Frankfurt Fire Chief Ernst Achilles. The SCBA safety controls are part of a comprehensive safety and accident prevention program administered under Achilles’ direction.

All SCBA in the department has been standardized to assure familiarity with valves and gages by fire fighters, and to provide interchangeability of facepieces and backpack units. At least two manufacturers provide SCBA to the department. However, all apparatus are interchangeable and identical in operating characteristics.

Carry masks on belt

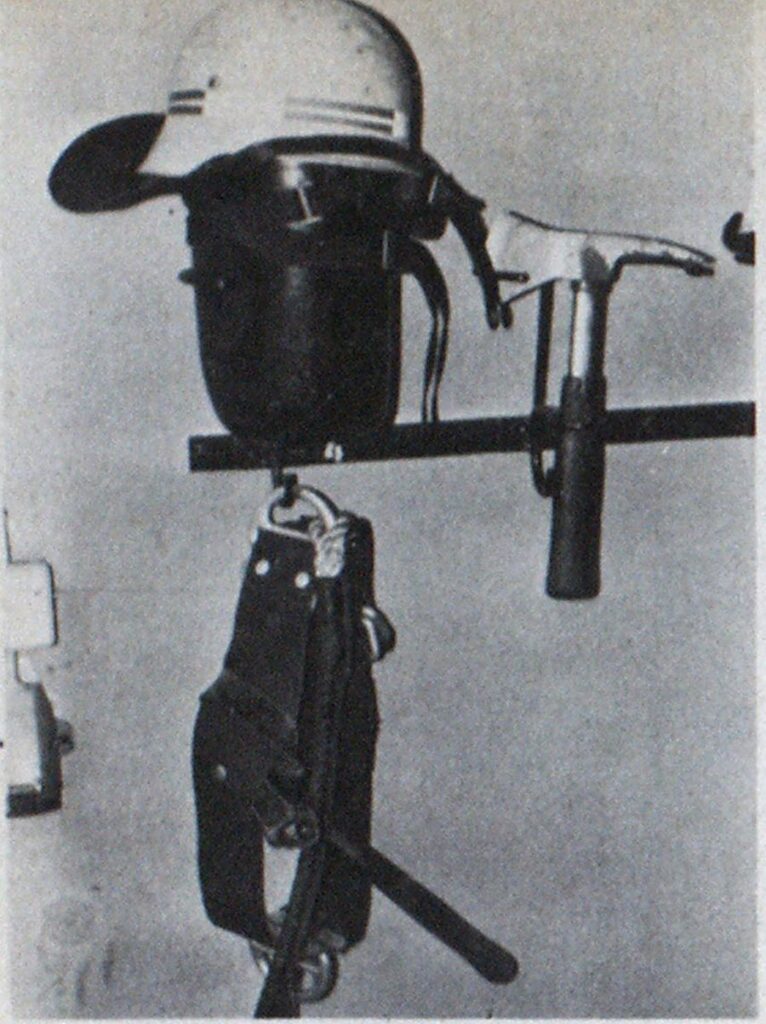

The department takes advantage of the interchangeability of backpack units with facepieces by issuing a facepiece to each fire fighter. Facepieces are available in three face sizes. A fire fighter is required to fit the mask to the configuration of his face each time he receives a replacement. The fitted facepiece is carried in a leather case on the fire fighter’s safety belt, and it is a mandatory part of the uniform at emergency calls. After a fire fighter uses his facepiece, he returns it to the department in exchange for one which has been inspected and tested in the fire department laboratory.

All SCBA in the department are positive pressure. Demand-type SCBA was eliminated from service in favor of the positive pressure type, which provides maximum protection against undetected leakage.

The twin-tank backpack unit provides approximately 45 minutes of air under normal operation. The cylinders are somewhat smaller than the standard American 30-minute cylinders and they fit closer to the contour of the fire fighter’s back, providing additional clearance in cramped spaces.

Fireground procedures

Each department engine and truck carries three backpack assemblies. Fire fighters requiring respiratory protection obtain their initial backpack units from their assigned apparatus and use their prefitted facepiece to complete the SCBA unit.

Department standard operating procedures require an officer to notify central dispatch whenever he commits more than two SCBA units at any incident. Once such notification is received, a specially equipped van, manned by three fire fighters trained as SCBA maintenance technicians, is dispatched to the scene. The van contains 25 additional backpack units, which are issued as replacements when the air supplies of working fire fighters are depleted. The van also contains air sampling facilities as well as equipment to handle all types of hazardous material incidents.

Depleted backpack units are turned in to the SCBA technicians for inspection, recharging and testing. Normally, depleted backpacks are not returned to an operation prior to complete laboratory testing to ensure that all components are operating correctly.

Units checked at lab

Used SCBA equipment is normally returned to the department SCBA laboratory in Fire Station 7. There the technicians disassemble the equipment for cleaning and inspection. After completing a visual inspection, cleaning, and disinfecting procedure, each facepiece and backpack has all operating components tested on an SCBA testing machine.

Facepieces are tested on a mannequin face by charging the mask with air. The test detects leaks in the mask and lowpressure hose, and it checks for proper operation of the intake and exhalation systems.

The backpack proof test includes testing the proper operation of the regulator, determining proper air volume deliveries at both sides of the regulator, and checking air delivery pressures and pressure gages.

Mobile recharging unit

A mobile SCBA recharging and testing laboratory is on the ready line at Station 7, available for dispatch to incidents requiring extensive use of SCBA equipment. The mobile laboratory is manned by the fire fighter technicians who normally work in the laboratory, and the vehicle contains 45 additional units prepared for immediate issue.

The mobile laboratory is equipped for on-site inspection, recharging and testing of SCBA units. Included in the equipment carried in the mobile laboratory is a high-pressure air compressor and filtering system, SCBA testing equipment, maintenance tools, a sink, and adequate bench space for inspecting and cleaning the equipment.

Frankfurt’s respiratory protection safety control program assures fire fighters that their equipment has met strict inspection and test standards and gives them the confidence that they can perform their duties with a minimum of concern about their breathing apparatus.